A production process of a logistics pallet

A production process and pallet technology, applied in the direction of textiles and papermaking, etc., can solve the problems of consuming large petrochemical resources, polluting the environment with waste products, and large heat deformation, etc., and achieve the effect of abundant sources, high degree of automation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

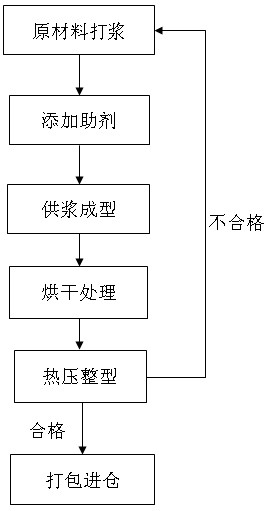

Method used

Image

Examples

Embodiment 1

[0029] 1) The raw material is beaten, the pulper is filled with water, the raw wood pulp is added, the motor is started for hydrolysis, the pulping time is set to 8 minutes, and the pulping concentration is guaranteed to be 5%;

[0030] 2) Adding additives, the slurry after beating is screened out by a vibrating screen to remove impurities in the wood pulp, and alkyl ketene polymer waterproofing agent, corn starch, and dehydration synergist are added in the thick stock tank. The three additives account for the total formula. The mass percentage content is: 1%, 5%, 0.5%, and the slurry is adjusted to a uniform level, and then supplied to the homogenization tank through a slurry pump;

[0031] 3) For slurry forming, select the fruit holder mold, install the mold on the press, set the suction time to 1.7s, the dehydration time to 8s, the mold passing time to 1s, and the demoulding time to 0.2s, and then the homogenate is directly supplied Forming machine, the forming machine uses...

Embodiment 2

[0036] 1) Beat raw materials, inject water into the pulper, add raw wood pulp boards, start the motor for hydraulic disintegration, set the pulping time to 8 minutes, and ensure that the pulping concentration is 7%;

[0037] 2) Adding additives, the slurry after beating is screened out by a vibrating screen to remove impurities in the wood pulp, and alkyl ketene polymer waterproofing agent, corn starch, and dehydration synergist are added in the thick stock tank. The three additives account for the total formula. The mass percentage content is: 3%, 8%, 0.8%, and the slurry is adjusted to uniformity, and then supplied to the homogenization tank through the slurry pump;

[0038] 3) Slurry supply molding, select the load-bearing tray mold, install the mold on the press, set the slurry suction time to 1.7s, the dehydration time to 8s, the mold passing time to 1s, and the demoulding time to 0.2s, and then the homogenate is directly supplied Forming machine, the forming machine uses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com