Method and device for controlling heat transfer performance of droplet condensation on superhydrophobic surface

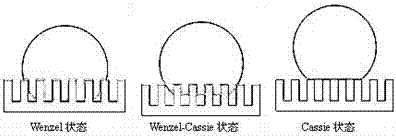

A technology of super-hydrophobic surface and heat transfer performance, applied in the field of heat transfer enhancement and control, can solve problems such as corrosion, droplets cannot fall off quickly, super-hydrophobic surface failure, etc., to achieve the effect of heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

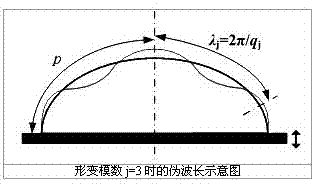

Method used

Image

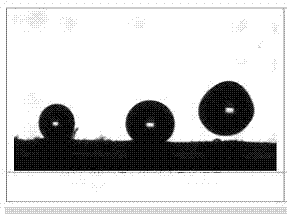

Examples

specific Embodiment approach

[0063] Depend on Figure 6 As shown, a drop-shaped condensation heat transfer performance control device, the device includes steam inlet 1, condensed water outlet 2, cooling water inlet 3, cooling water outlet 4, tube plate 5, cooling water return chamber 6, micro-vibration transduction 7, real-time control computer 8, heat transfer performance detection unit 9, micro-vibration transducer control bus 10, flow temperature signal bus 11, control cabinet 12, the upper end of the drop-shaped condensation heat transfer performance control device has a steam inlet 1. There is a condensed water outlet 2 at the lower end, and a cooling water inlet 3 and a cooling water outlet 4 are opened up and down the left side. The condensed water outlet 2 is connected to a heat transfer performance detection unit 9. The drop-shaped condensation heat transfer performance A cooling water return chamber 6 is built inside the control device, and the cooling water return chamber 6 is formed by a flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com