Surface mount type power led bracket manufacturing method and product thereof

A LED bracket and surface mount technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of poor heat dissipation, poor heat resistance, and low yield of ordinary insulating boards, and achieve good light output and excellent durability. Effects of thermal performance and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

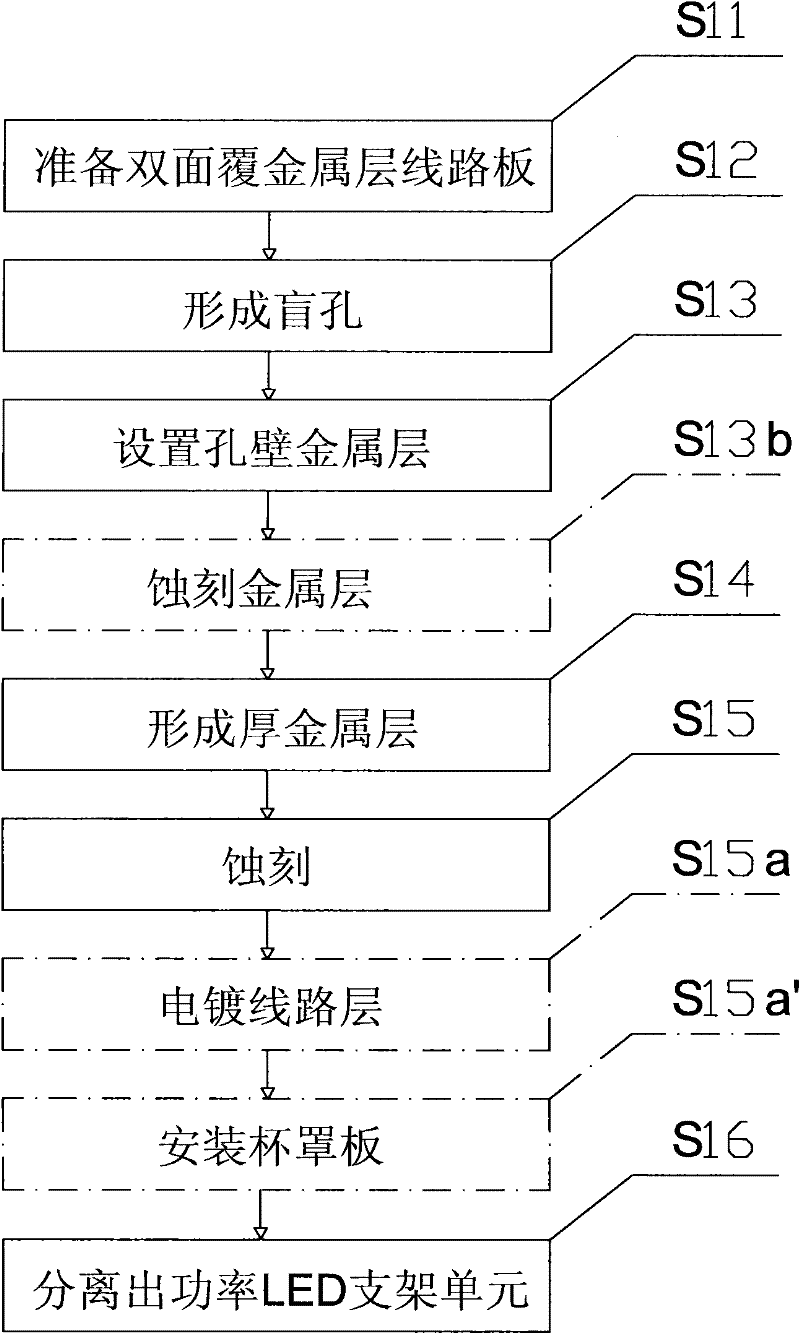

[0051] according to image 3 and Figure 4 Shown is Embodiment 1 of a method for manufacturing a power LED bracket provided by the present invention.

[0052] Such as image 3 Provided the process flow chart of the present embodiment, in conjunction with Figure 4 The schematic diagram of the process steps is given, and the specific manufacturing steps of this embodiment are described as follows.

[0053] Step S11) preparing a double-sided metal-clad circuit board:

[0054] Prepare a double-sided metal-clad circuit substrate 1, such as Figure 4 As shown in A, it includes a common insulating substrate 10 , a metal layer 1 1 covering the upper surface of the substrate, and a metal layer 2 12 covering the lower surface of the substrate 10 . The material of the substrate 10 has no special requirements, it is an ordinary insulating board, such as a PCB board, preferably, a cheap glass fiber cloth substrate, CEM-3 (3 grade composite epoxy material, English Composit Epoxy Mater...

Embodiment 2

[0074] according to Figure 5 and Figure 6 Shown is Embodiment 2 of a method for manufacturing a power LED bracket provided by the present invention.

[0075] Such as Figure 5 Provided the process flow chart of the present embodiment, in conjunction with Figure 6 The schematic diagram of the process steps is shown, and the specific manufacturing steps of this embodiment are described as follows.

[0076] Step S21) preparing a double-sided metal-clad circuit board:

[0077] Prepare a double-sided metal-coated circuit substrate 2, including an ordinary insulating substrate 20, a metal layer 21 covering the upper surface of the substrate, and a metal layer 2 22 covering the lower surface of the substrate; the material of the substrate 20 has no special requirements , is an ordinary insulating board, such as a PCB board, preferably, a cheap glass fiber cloth substrate (FR-4), CEM-3 (3-level composite epoxy material, English Composit Epoxy Material Grade-3), CEM -1 (Class 1...

Embodiment 3

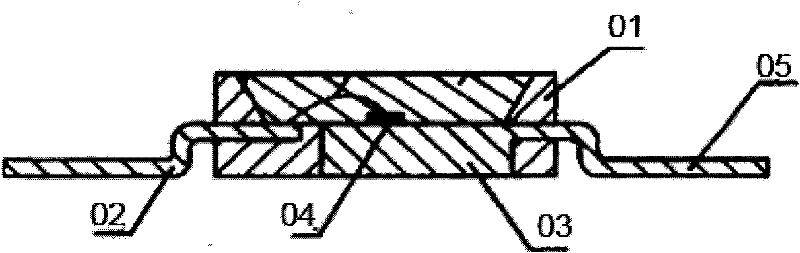

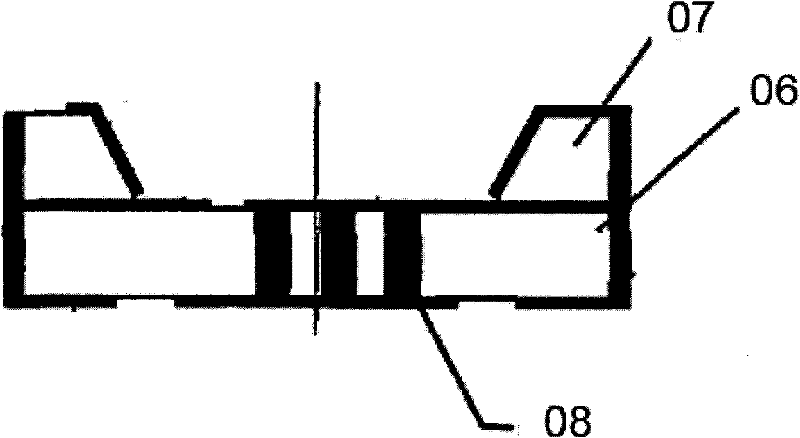

[0098] according to Figure 7 As shown, a power LED bracket provided by the present invention has a structure including: a double-sided metal-clad circuit board is a bracket substrate 3, at least one through hole 31 is arranged on the bracket substrate 3, and a through hole 31 The positive and negative electrodes 32 on both sides and the chip placement portion 351 at the bottom of the through hole 31 . Wherein, the support substrate 3 is composed of a metal layer 33, a metal layer 2 34 and an insulating substrate placed between the two metal layers; preferably, the positive or negative electrodes 32 each include at least one through The small electrode through hole 321 of the support substrate 3 is provided with a conductive layer 322 or filled with a conductive material (not marked) on the inner wall of the small electrode through hole 321; surrounding, the lead connecting portion 331 for welding metal wires, and the positive and negative electrode layer 1 332 located on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com