Edible vegetable oil with lower trans fatty acid and refining method thereof

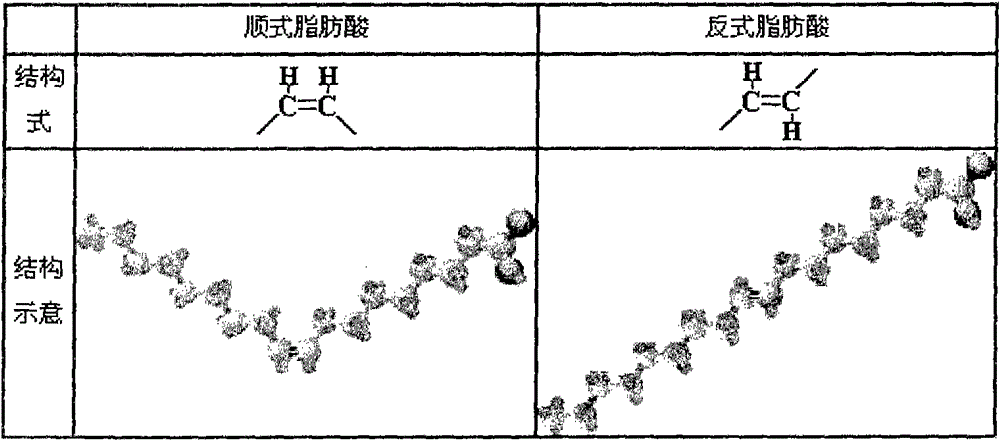

A technology of trans fatty acid and edible vegetable oil, applied in the direction of fat oil/fat refining, fat production, food science, etc., can solve the problems that vegetable oil cannot meet the purity and storage resistance, reduce deodorization temperature, brain function decline, etc., and achieve trans fatty acid The effect of low content, purity and storage resistance, and high smoke point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 400 tons of soybean oil, its crude oil quality: FFA=0.51% PV=2.47meq / kg Impurities: 0.03% Phospholipids: 61.36ppm

[0040] Refining 200 tons of soybean oil according to conventional process conditions, namely: crude oil→degumming→deacidification→desoaping→dehydration→decolorization→deimpurity→deoxidation→deodorization→cooling→finished product

[0041] The parameters of each section are as follows: according to the oil content 0.1wt%, evenly add phosphoric acid; according to the free fatty acid content, evenly add caustic soda and superalkali 15%; according to the oil quantity 10wt%, add soft water for washing; then, according to the oil quantity 1.2wt%, add clay for decolorization, The secondary filter element is 25μm, the deodorization temperature is 255°C, the deodorization flow rate is 10500L / h, the deodorization time is 45min, and the vacuum is maintained at 4τ; after all of them are refined, a mixed sample is taken for inspection.

[0042] The remaining 200 tons of...

Embodiment 2

[0049] 400 tons of canola oil, the quality index of crude oil is as follows: FFA=0.42% PV=2.8meq / kg Impurities: 0.03% Phospholipids: 31.3ppm

[0050] Refining 200 tons of canola oil according to conventional process conditions, the parameters of each section are as follows: add phosphoric acid evenly according to the oil content 0.08wt%; add caustic soda evenly according to the free fatty acid content and super alkali 15%; After washing with soft water; according to the oil content of 1.2wt%, clay is added for decolorization. The secondary filter element is 25μm, the deodorization temperature is 255°C, and the deodorization flow rate is 10500L / h.

[0051] Refining the remaining 200 tons of canola oil according to the method of the present invention, replacing the secondary filter element with 10 μm, pressurized filtration to maintain the normal flow rate; the deodorization temperature is set at 240 °C, the flow rate is 10500 L / h, and the deodorization time After 45 minutes, a...

Embodiment 3

[0058] Compared with 400 tons of dewaxed corn oil that has been neutralized and decolorized, its quality indicators are as follows: FFA=0.20% PV=1.57meq / kg Impurities 0.01% Phosphorus 0.56ppm

[0059] 200 tons of dewaxed corn oil were refined, decolorized and deodorized according to conventional process conditions (since the oil has been dewaxed, there is only a decolorization and deodorization section). Add clay according to 0.8wt% of the oil amount, the filter element is 25μm, the deodorization temperature is 260°C, the vacuum is maintained at 4τ, the flow rate is 10000L / h, and the deodorization time is 45min.

[0060] Refining the remaining 200 tons of dewaxed corn oil according to the method of the present invention, replacing the secondary filter element with 10 μm, pressurized filtration to maintain the normal flow rate; the deodorization temperature is set at 245 ° C, the flow rate is 10500 L / h, and the deodorization time is 45 minutes. Adjust the vacuum to be stable at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com