Weakly polar cigarette paper filter material and preparation and application methods thereof

A weak-polar, paper-based technology, applied in the application, e-liquid filter, tobacco, etc., can solve the problem that it is difficult to fundamentally improve the sensory quality of cigarettes with paper filter materials, and does not involve the evaluation of the impact of dry paper odor absorption, etc. problems, to achieve the effect of high industrialization realization, improved impact, and mature process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

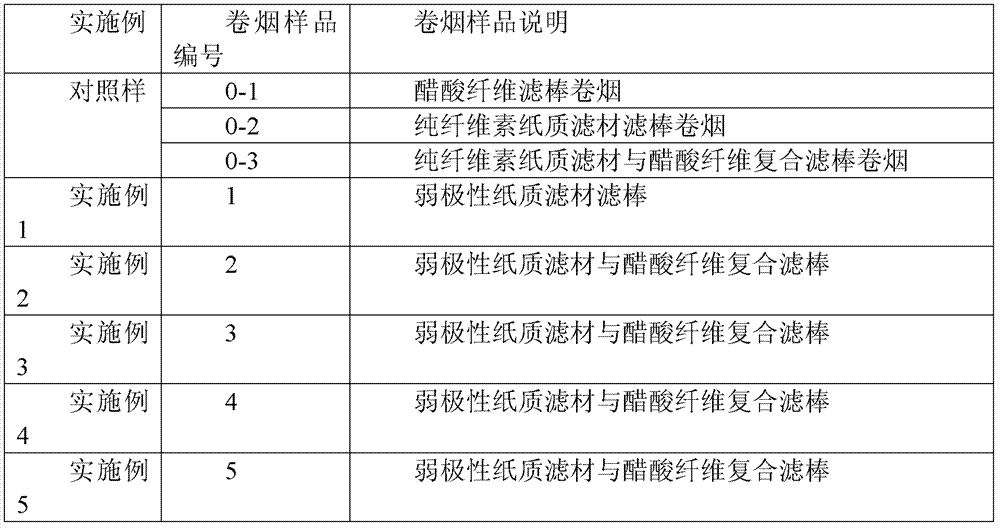

Embodiment 1

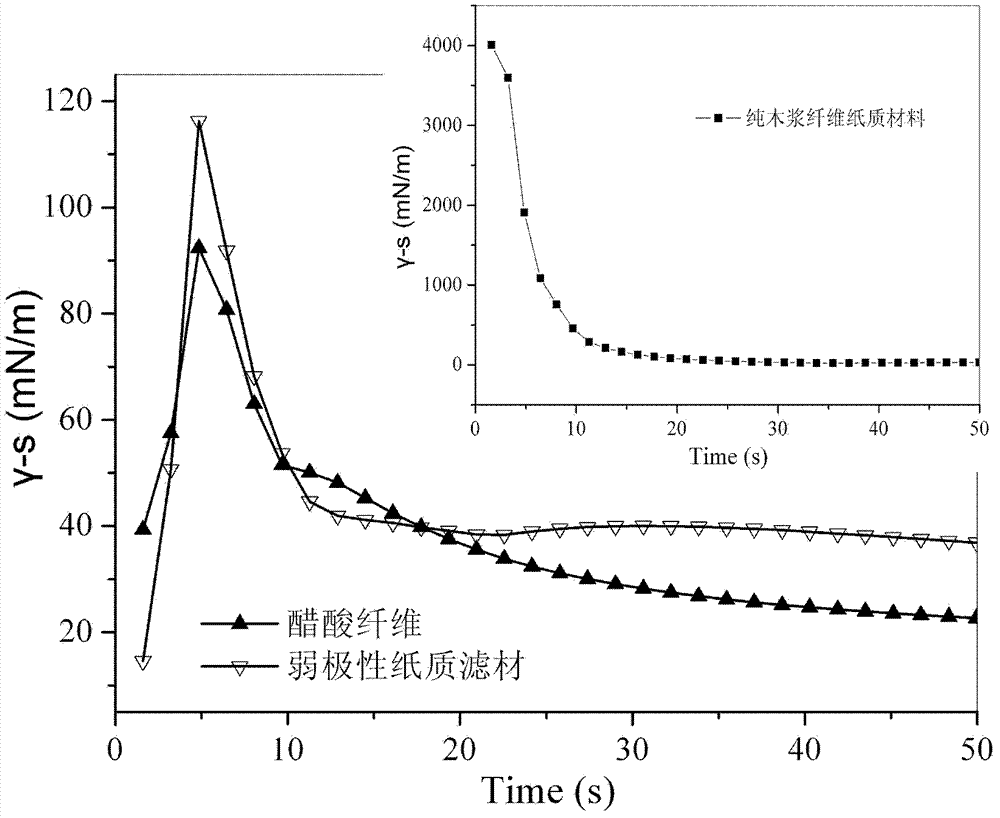

[0026] Mix wood pulp fiber and polypropylene fiber, and polypropylene fiber accounts for 20% of the total weight. After the mixed fiber is disintegrated, disc-grinded and beaten, polyethyleneimine with 1% dry pulp weight is added to the slurry, and it is prepared by wet method. Paper, to obtain a grammage of 35g / m 2 paper filter base paper.

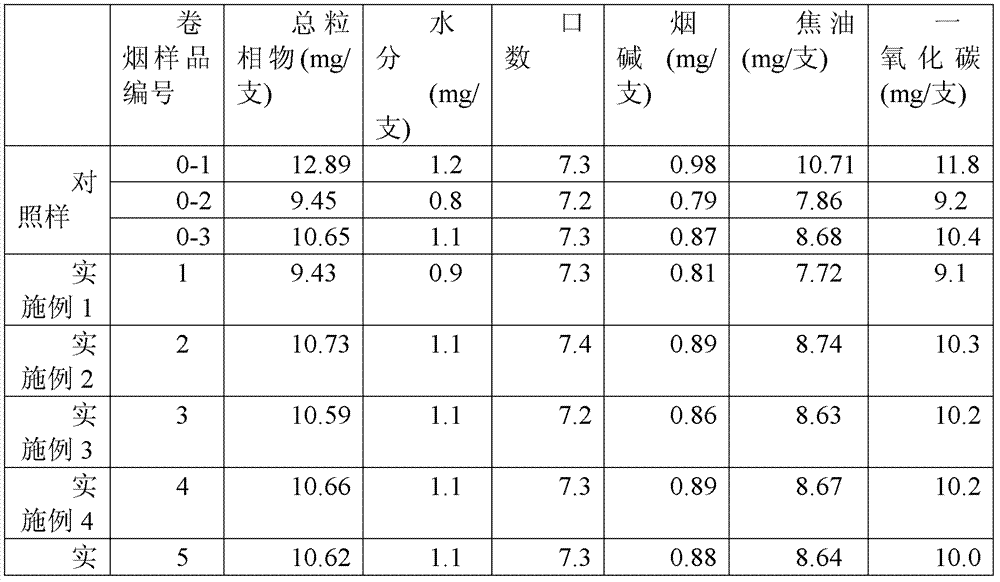

[0027] After cutting and embossing the obtained weak polarity paper filter material, it is molded to prepare cigarette paper filter rods, and then coiled to prepare cigarettes. The smoke analysis and sensory quality evaluation of cigarettes with weak polarity paper filter materials were carried out, and it was found that compared with the control cigarettes with cellulose acetate filter sticks, the tar was significantly reduced, and the sensory quality evaluation of cigarettes was basically the same; In comparison, the tar level was basically the same, but the sensory quality of cigarettes was significantly improved.

Embodiment 2

[0029] The wood pulp fiber and the polyethylene fiber are disentangled, disc-grinded and beaten respectively, and the polyethylene fiber accounts for 10% of the total weight, then the two kinds of pulp are mixed in proportion by weight, and 0.8% of dry pulp weight of dialdehyde is added in the pulp Starch, papermaking by wet process, to obtain a grammage of 40g / m 2 paper filter base paper.

[0030] After cutting and embossing the obtained weak polarity paper filter material, it is molded to prepare a cigarette paper filter rod, and the paper filter rod and acetate filter rod are compounded according to the ratio of length 10:15 to prepare a composite filter rod. Rod, and then paper / acetate fiber composite filter rod was wound to prepare cigarettes.

[0031]Smoke analysis and cigarette sensory quality evaluation were carried out on the weak polarity paper filter material composite filter stick cigarettes, and it was found that compared with the control cellulose acetate filter...

Embodiment 3

[0033] The wood pulp fiber and the polystyrene fiber are disentangled respectively, disc grinding and beating, the polystyrene fiber accounts for 8% of the total weight, then the two kinds of slurry are mixed in proportion by weight, and 0.7% of dry pulp weight is added in the slurry Sodium dodecylbenzene sulfonate and 1.5% polyethyleneimine, wet-laid to give a grammage of 36 g / m 2 paper filter base paper.

[0034] After cutting and embossing the obtained weak polarity paper filter material, it is molded to prepare a cigarette paper filter rod, and the paper filter rod and acetate filter rod are compounded according to the ratio of length 10:15 to prepare a composite filter rod. Rod, and then paper / acetate fiber composite filter rod was wound to prepare cigarettes.

[0035] Smoke analysis and cigarette sensory quality evaluation were carried out on the weak polarity paper filter material composite filter stick cigarettes, and it was found that compared with the control cellul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com