A kind of steam explosion pretreatment method of Ginkgo biloba

A technology of Ginkgo biloba leaves and pretreatment, which is applied in directions such as medical raw materials derived from Ginkgo biloba, can solve the problems of increased energy consumption, increased cost, and affected extraction efficiency processing process, etc., and achieves the effects of enhancing the degree of damage and improving the dissolution efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

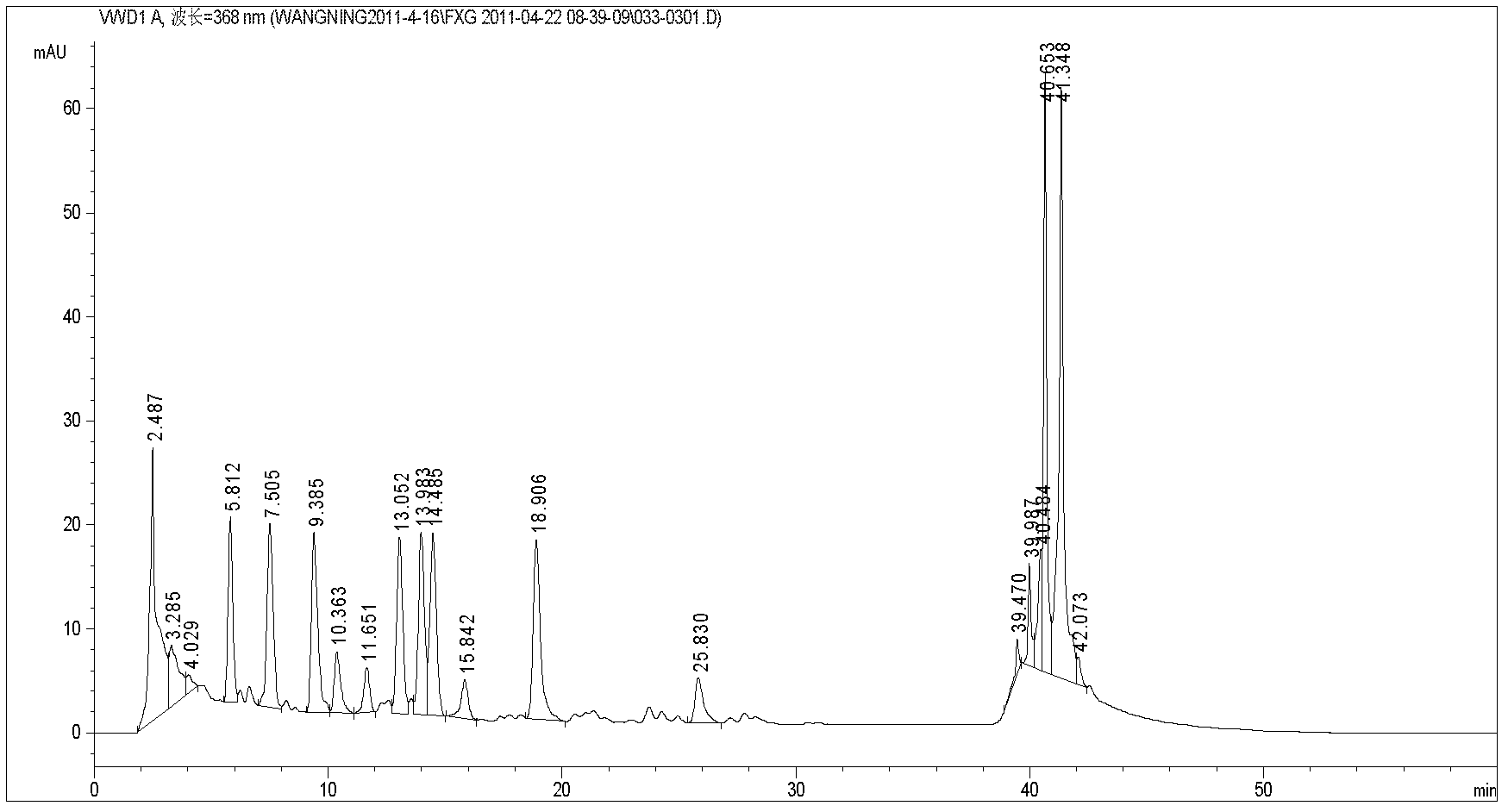

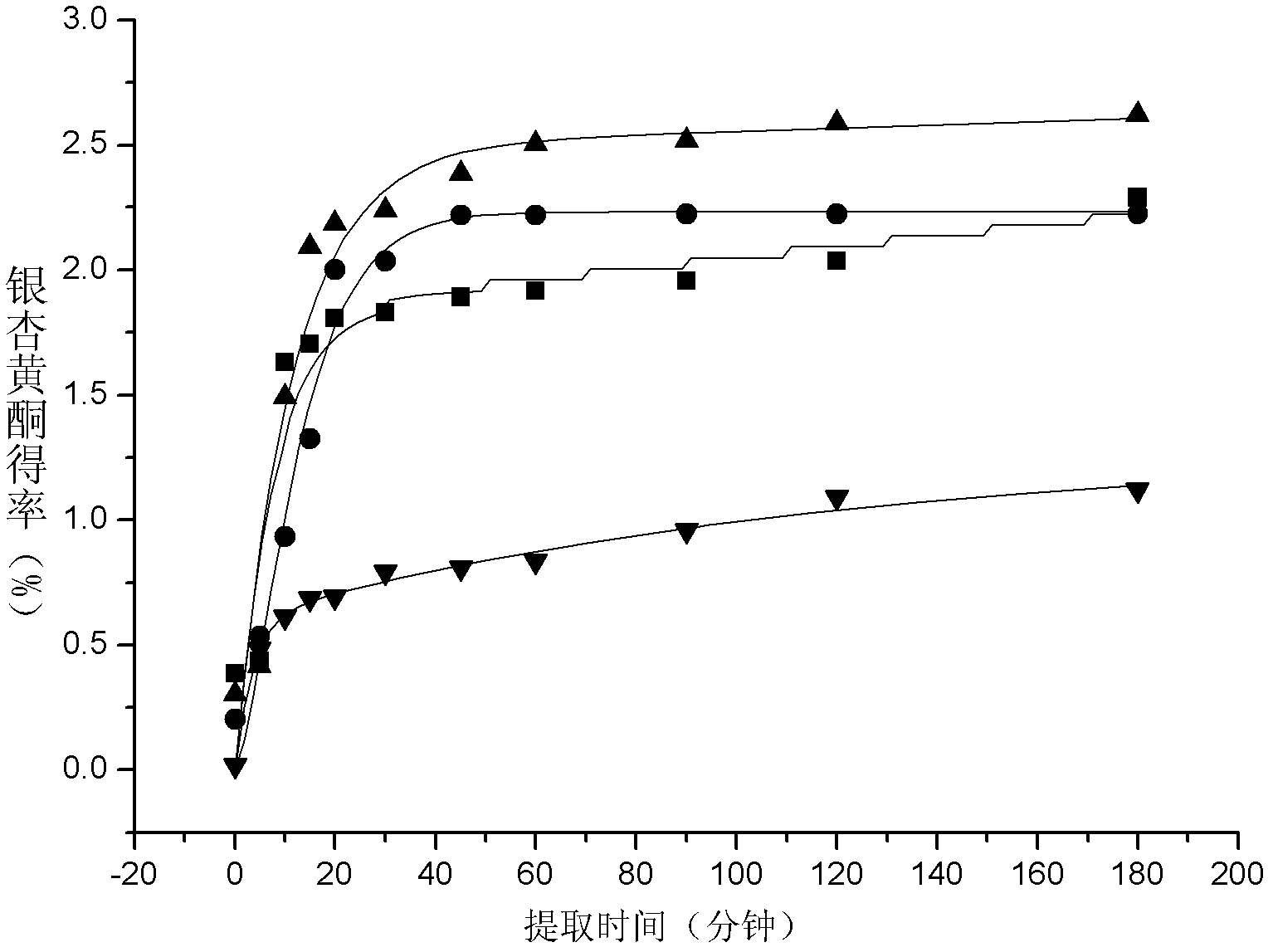

Embodiment 1

[0024] Add the solution according to the ratio of 1:1 of the quality of the dry ginkgo leaves and the acetic acid solution of pH4.0, and then soak for 30 minutes at room temperature; Put liquid nitrogen into the tank to make the temperature in the tank reach 180°C, maintain it for 5 minutes, and then carry out steam explosion treatment; then quickly release the pressure, release the material processed in the steam explosion tank into the normal pressure container, and obtain the material after gas explosion pretreatment. Grind the steam-exploded ginkgo leaves and the original untreated ginkgo leaves to 60 mesh with a plant pulverizer, add 70% ethanol solution at a liquid-solid ratio of 20:1 (mL / :g), heat and reflux in a water bath at 85°C for 2 hours, filter, The filtrate is reclaimed, the filter residue is repeatedly extracted 3 times as described above, the filtrate is combined, and the extraction rate of the total flavonoids of Ginkgo biloba is measured in the filtrate: 2.49...

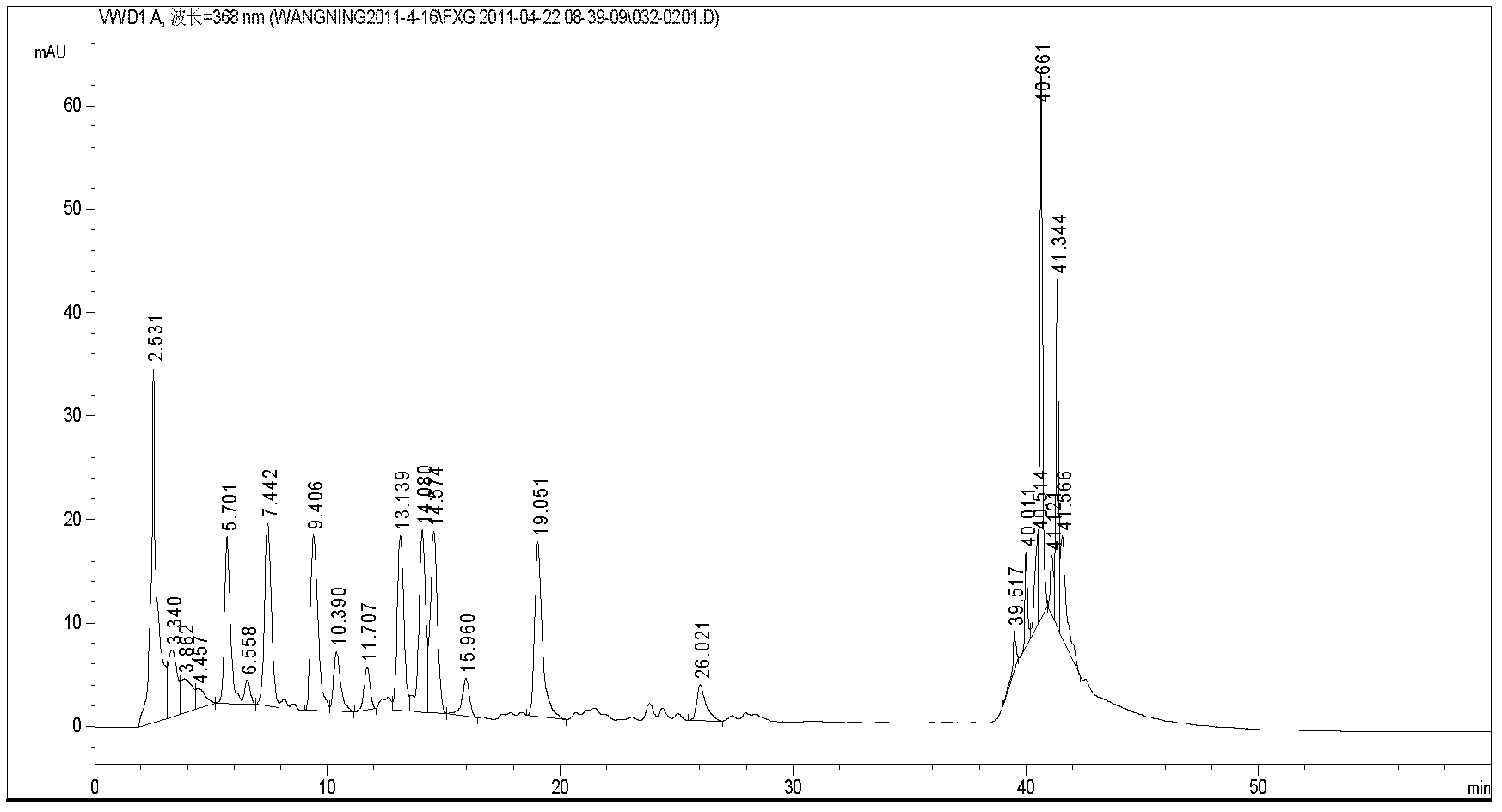

Embodiment 2

[0026] Add distilled water according to the ratio of 1:2 of the quality of dry ginkgo leaves and distilled water, and then soak at normal temperature for 60 minutes; put the soaked material in the steam explosion tank, and feed ozone to make the temperature in the tank reach 150 ° C. After 30 minutes, the steam explosion treatment is carried out; then the pressure is quickly released, and the material processed in the steam explosion tank is released into the normal pressure container, and the material after the gas explosion pretreatment is obtained. Grind the steam-exploded ginkgo leaves and the original untreated ginkgo leaves to 60 mesh with a plant pulverizer, add 70% ethanol solution at a liquid-solid ratio of 20:1 (mL / :g), heat and reflux in a water bath at 85°C for 2 hours, filter, Reclaim filtrate, filter residue is repeatedly extracted 3 times by above-mentioned method, merges filtrate, measures the extraction rate of ginkgo total flavonoids in the filtrate: 2.18g tot...

Embodiment 3

[0028] Add the solution according to the ratio of 1:3 of the quality of the dry ginkgo leaves and the sodium hydroxide solution of pH 10.0, and then soak at room temperature for 60 minutes; put the soaked material in the steam explosion tank, and feed nitrogen to make the tank The internal temperature reaches 200°C and is maintained for 1 minute before steam explosion treatment; then the pressure is quickly released, and the material treated in the steam explosion tank is released into the normal pressure container, and the material after gas explosion pretreatment is obtained. Grind the steam-exploded ginkgo leaves and the original untreated ginkgo leaves to 60 mesh with a plant pulverizer, add 70% ethanol solution at a liquid-solid ratio of 20:1 (mL / :g), heat and reflux in a water bath at 85°C for 2 hours, filter, Reclaim filtrate, filter residue is repeatedly extracted 3 times by above-mentioned method, merges filtrate, measures the extraction rate of ginkgo total flavonoids...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com