A Method for Cutting 170μm Silicon Wafer

A technology for silicon wafers and cutting fluids, applied in the directions of cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of silicon wafer damage, cleaning, uncleanness, affecting the yield and quality of silicon wafers, etc. Achieve the effect of reducing thickness, reducing production cost, improving film yield and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with specific embodiment, further illustrate the present invention, should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention, after having read the present invention, always adopt the mode of equivalent replacement or equivalent transformation to obtain The technical solutions all fall within the protection scope of the present invention.

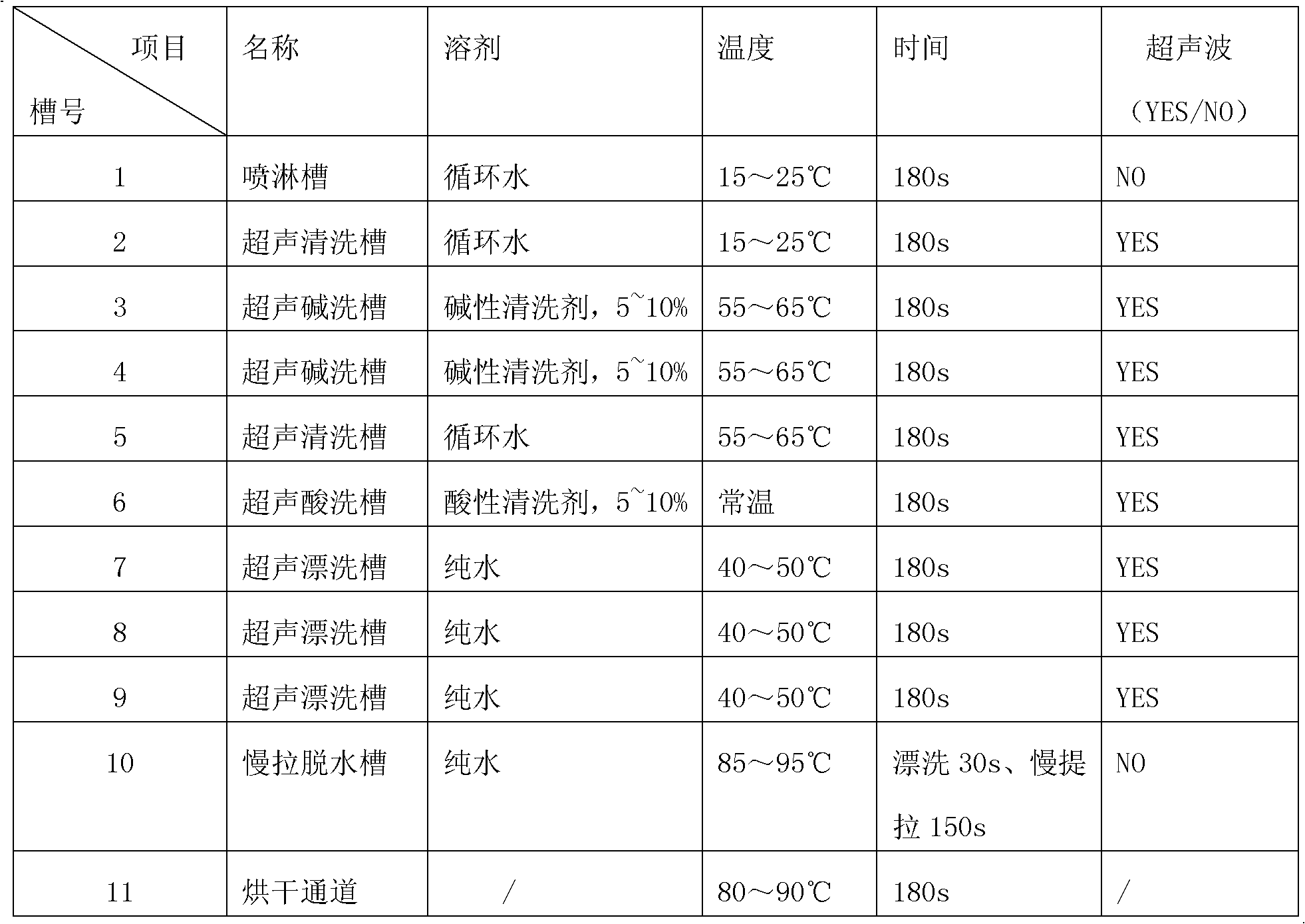

[0037] A method for cutting a 170 μm silicon wafer, comprising the steps of:

[0038] 1. Bonding silicon ingots: first put the silicon ingots and glass plates into an ultrasonic water tank for cleaning, the cleaning water temperature is 30-40°C, the cleaning time is 15min, and then in an environment of 25±3°C and humidity ≤60% , the silicon ingot and the glass plate are bonded together with glue, and the amount of glue is 0.5-0.7g / cm 2 , according to the calculation of the bonding surface of the silicon ingot an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotational viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com