Special colored hot-press label of resin grinding wheel

A resin grinding wheel and color technology, which is applied in the field of labels, can solve the problems of single color, large color change range, and low efficacy, and achieve the effects of dense and stable chemical structure, increased ink viscosity, and high pigment concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

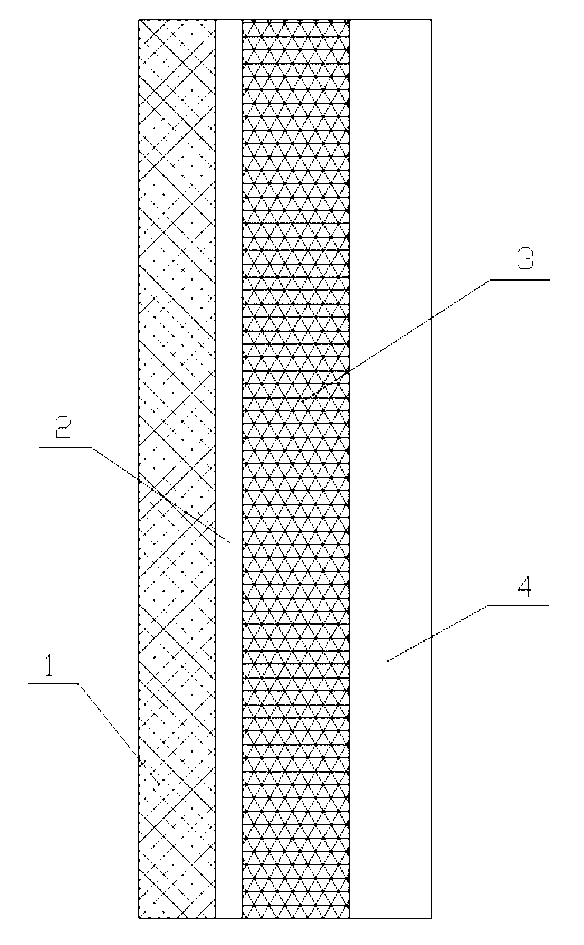

[0021] Such as figure 1 As shown, the color hot-pressed label for resin grinding wheels of the present invention includes a black cardboard or coated paper base layer 1, and a bottom layer 2, a pattern ink layer 3, and a protective layer 4 that are sequentially offset printed on the base layer 1. The bottom layer 2 can be filled with paper The unevenness and opacity of the surface protects the paper surface from being chalked by high temperature, effectively improves the ability to carry the ink layer, makes the ink layers of various colors firmly bonded, and can also change the hue of the base layer to silvery white, which is easier to show the subsequent colors; The pattern ink layer 3 can be laminated with 2-7 layers; the outer protective layer 4 can improve the abrasion, water and oil resistance of the finished label.

[0022] In order to reduce the discoloration range and adapt to the hot pressing and high temperature vulcanization process of the grinding wheel, the printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com