Method for preparing baking soda and white carbon black from rice husk power generation waste

A technology of baking soda and white carbon black, applied in chemical instruments and methods, alkali metal compounds, silicon dioxide, etc., can solve the problems of unsatisfactory economic value and unusable physical and chemical properties of caustic soda, and achieve high economic value, The effect of profit improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

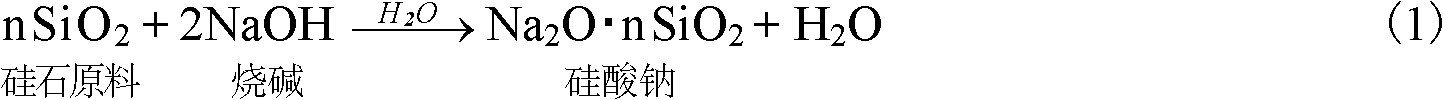

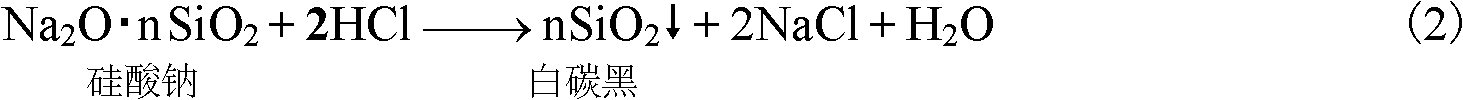

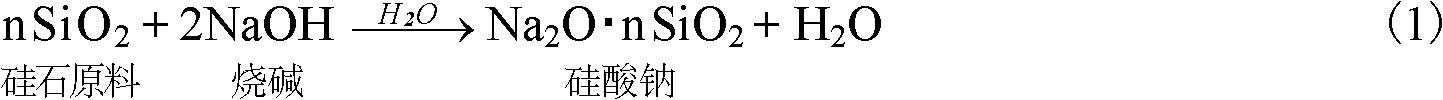

Method used

Image

Examples

Embodiment 1

[0094] Add 1500 grams of 15% caustic soda solution to the pressure reactor with stirring, and then add 500 grams of rice husk ash with a silicon dioxide content of 67.5%, and react at 160° C. and corresponding saturated steam pressure for 75 minutes to complete the reaction. The reaction product is filtered, and the filter residue is watered twice, each time the water consumption is three times the weight of the filter residue, and the washing water is recovered and incorporated into the silicic acid nanofiltrate, and then washed with water until the pH is 8 to 7, and then dried to obtain a specific surface of 650m 2 159 grams per gram of activated carbon. Filtrate is Na 2 O and SiO 2 The sodium silicate solutions with contents of 9.49% and 18.36% respectively, weighing 1780 grams, were carbonized according to the following steps.

[0095] Add 650 grams of the above-mentioned sodium silicate solution into a stirred reactor, add 1500 milliliters of water to dilute (total vol...

Embodiment 2

[0097] Add 450 grams of rice husk ash with a silica content of 74.1% to the pressure reactor with stirring, and then add 1100 grams of 20% caustic soda solution, and react at 200° C. and corresponding saturated steam pressure for 60 minutes. Filter the reaction product, firstly dilute the filter residue with water twice, each time the water consumption is three times the weight of the filter residue, wash water recovery and merge into silicate nanofiltrate, continue to wash with water until pH 8-7, and then dry to obtain a specific surface area of 635m 2 114 grams of active carbon per gram; Filtrate weighs 1390 grams, is the sodium silicate solution that sodium oxide and silicon dioxide content are respectively 11.9% and 23.2%, prepare baking soda and white carbon black by following carbonization step:

[0098] Add 500 grams of the above-mentioned sodium silicate solution into a stirred reactor, control the temperature at 75° C., add 1800 grams of 13.5% sodium bicarbonate sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com