A kind of preparation method of metavanadate nanocrystal/polymer composite fluorescent film

A technology of metavanadate and composite fluorescence, which is applied in the field of preparation of metavanadate nanocrystal/polymer composite fluorescent film, which can solve the problems of serious pollution, cumbersome process, and unstable luminescent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0138] The present invention will be further explained below in conjunction with the drawings:

[0139] figure 1 Shown is the state diagram of polyacrylamide gel. The position of each part should be correct, proportioning according to quantity, and operation in order.

[0140] The chemical materials used in preparation are determined according to the preset range, in grams, milliliters, millimeters, centimeters 3 It is the unit of measurement.

[0141] The invention can also use rubidium nitrate as a raw material to prepare a composite fluorescent film.

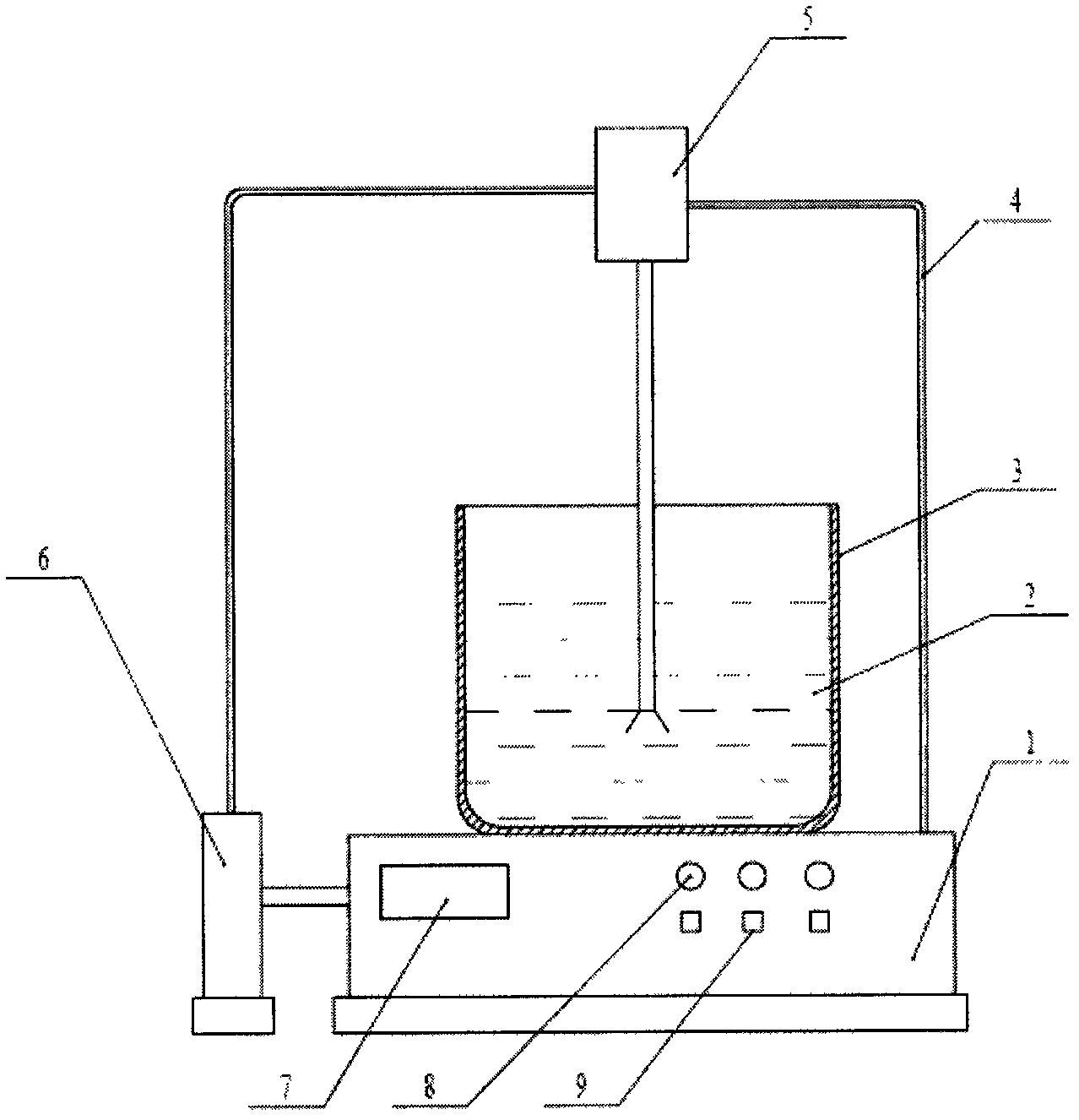

[0142] The polyacrylamide gel is carried out in a beaker. The beaker 3 is placed on the electric heater 1, the stirrer 5 is inserted into the beaker 3, and the stirrer 5 is fixed by the bracket 6; the electric heater 1 is provided with a display screen 7, Indicator light 8, control switch 9, electric heater 1 is connected to stirrer 5 through wire 4, and mixed solution 2 is in beaker 3.

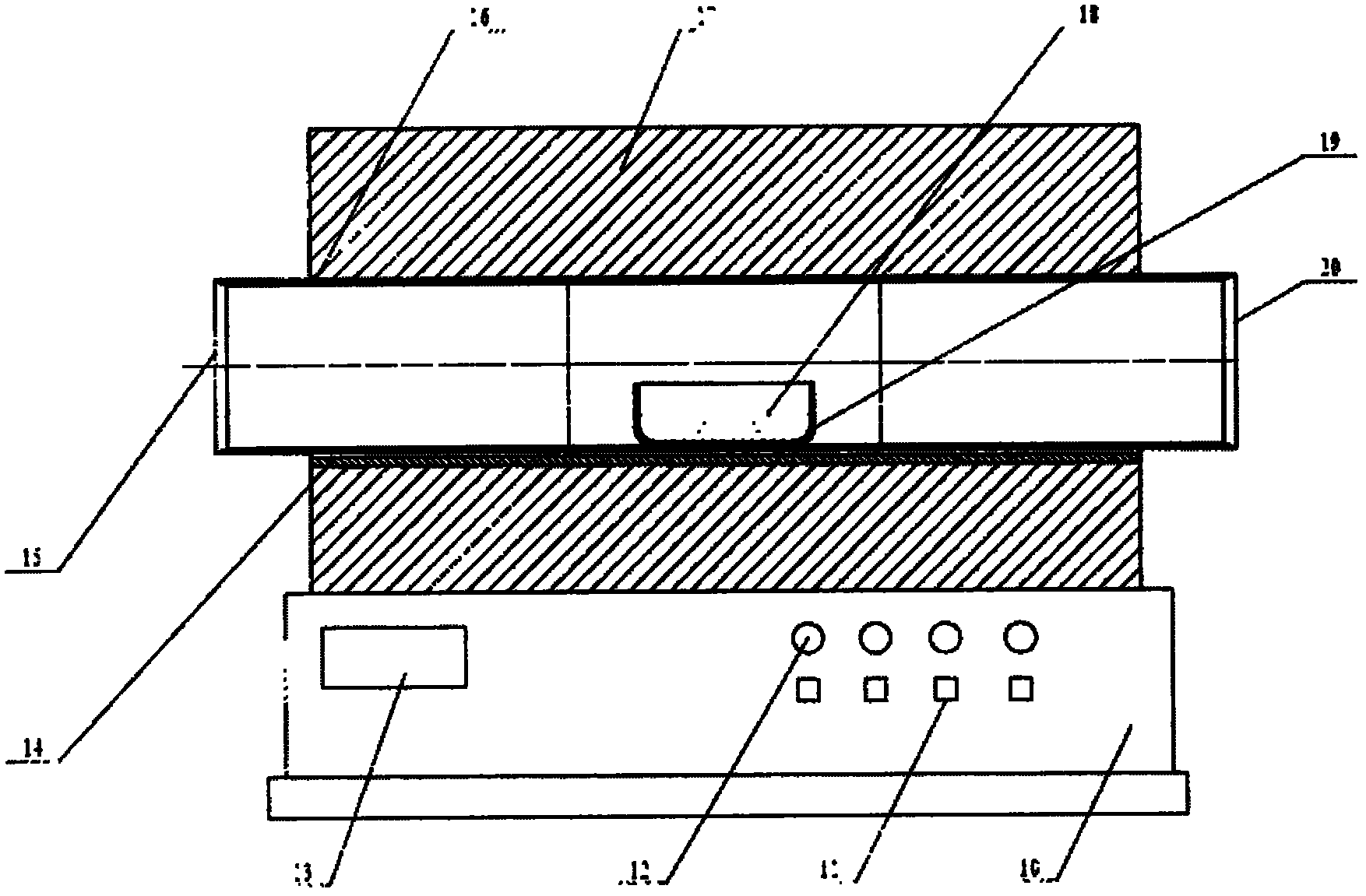

[0143] figure 2 Shown is the low-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com