A kind of chemical modification method of polymer powder

A technology of polymer and polymer particles, applied in the field of chemical modification of polymer powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

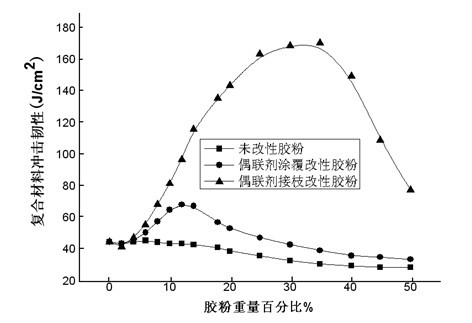

Image

Examples

Embodiment 1

[0046] Stir and disperse 100g of polymethylmethacrylate (PMMA) powder with an average particle size of 25μm into 300ml containing 5% diethylenetriamine (weight ratio, the same below), 15% KH-550 and 20% dilute hydrochloric acid (original concentration 15%) in diethylene glycol monomethyl ether solution. Ultrasonic treatment with 300W power for 10 minutes, then placed in a 900W power microwave generator to stir, put into the cooling water inner coil, the microwave generator works at half full power, control the temperature of the reaction system not to exceed 110°C, and react for a total of 20 minutes. The polymer powder was obtained by filtration, washed three times with ethanol (200 ml ethanol each time), and dried in vacuum. The C / Si atomic ratio on the surface of the polymer particles was determined to be 100:14.3 by XPS. Measured with a MasterSizer 2000 laser particle size analyzer (Malvern, UK), the average particle size has hardly changed and is still about 25 μm.

[0...

Embodiment 2

[0052] Stir and disperse 100g of polymethylmethacrylate (PMMA) powder with an average particle size of 5 μm into 300ml containing 5% diethylenetriamine (weight ratio, the same below), 20% diethylenetriaminopropyltrimethoxysilane (Veco A-1130) and 30% dilute hydrochloric acid (original concentration 15%) in diethylene glycol monomethyl ether solution. Ultrasonic treatment with 300W power for 10 minutes, then placed in a 900W power microwave generator to stir, put into the cooling water inner coil, the microwave generator works at 50% full power, control the temperature of the reaction system not to exceed 110°C, and react for 30 minutes in total . The polymer powder was obtained by filtration, washed three times with ethanol (200 ml ethanol each time), and dried in vacuum. The C / Si atomic ratio on the surface of the polymer particles was determined to be 100:16.2 by XPS. Measured with a MasterSizer 2000 laser particle size analyzer (Malvern, UK), the average particle size has...

Embodiment 3

[0055] Stir and disperse 100g of polymethylmethacrylate (PMMA) powder with an average particle size of 780μm into 300ml containing 5% diethylenetriamine (weight ratio, the same below), 10% N,N-bis-(triethoxy Silicon propyl) imine (G-402) and 10% dilute hydrochloric acid (original concentration 15%) in diethylene glycol monoethyl ether solution. Ultrasonic treatment with 300W power for 10 minutes, then placed in a 900W power microwave generator to stir, put into the cooling water inner coil, the microwave generator works at 80% full power, control the temperature of the reaction system not to exceed 110°C, and react for a total of 8 minutes . The polymer powder was obtained by filtration, washed three times with ethanol (200 ml ethanol each time), and dried in vacuum. The C / Si atomic ratio on the surface of the polymer particles was determined to be 100:21.5 by XPS. Measured with a MasterSizer 2000 laser particle size analyzer (Malvern, UK), the average particle size hardly c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com