A method of increasing light absorption of solar cells

A solar cell and light absorption technology, applied in the field of solar energy applications, to achieve the effects of low cost, fully compatible production process and abundant reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

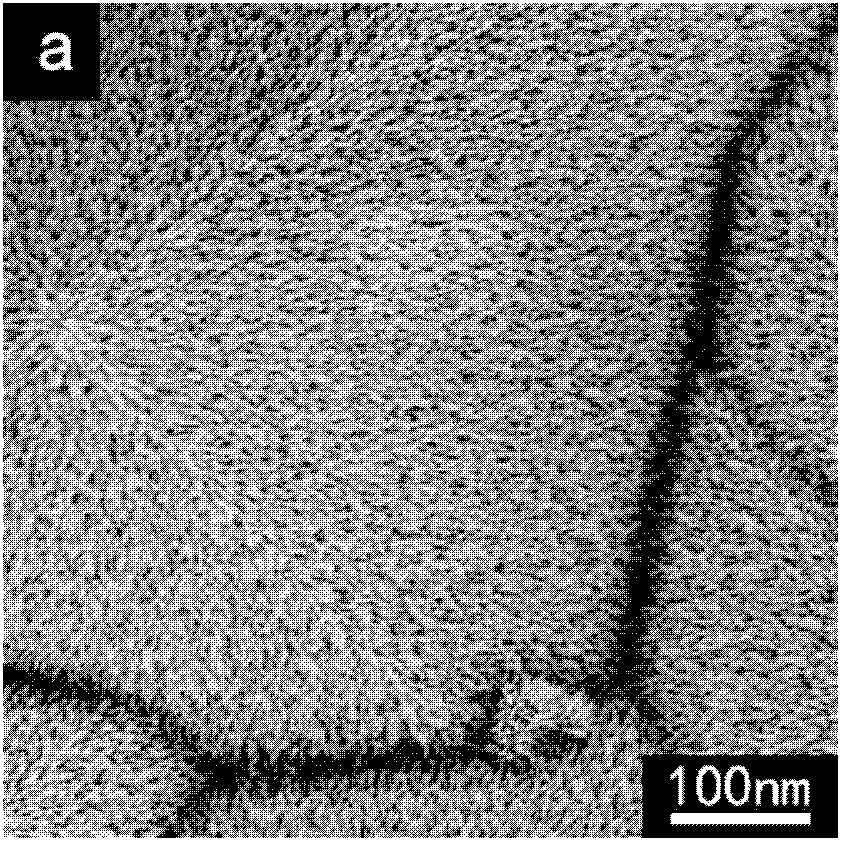

[0036] Disperse zinc oxide nanoparticles with a particle diameter of 80-100nm in water to form a solution with a volume concentration of 0.8% zinc oxide nanoparticles; then apply the solution on the surface by spin coating at a speed of 350rad / min On the light-receiving surface of the monocrystalline silicon solar cell, zinc oxide nanoparticles are uniformly dispersed on the light-receiving surface of the monocrystalline silicon solar cell; finally, the monocrystalline silicon solar cell coated with zinc oxide nanoparticles is naturally air-dried in the air.

[0037] The composition and structure of the product obtained above were characterized, and it can be seen from the XRD spectrum and scanning electron microscope photos that a layer of zinc oxide nanoparticles with a particle diameter of 80-100 nm grows on the light-receiving surface of the single crystal silicon solar cell.

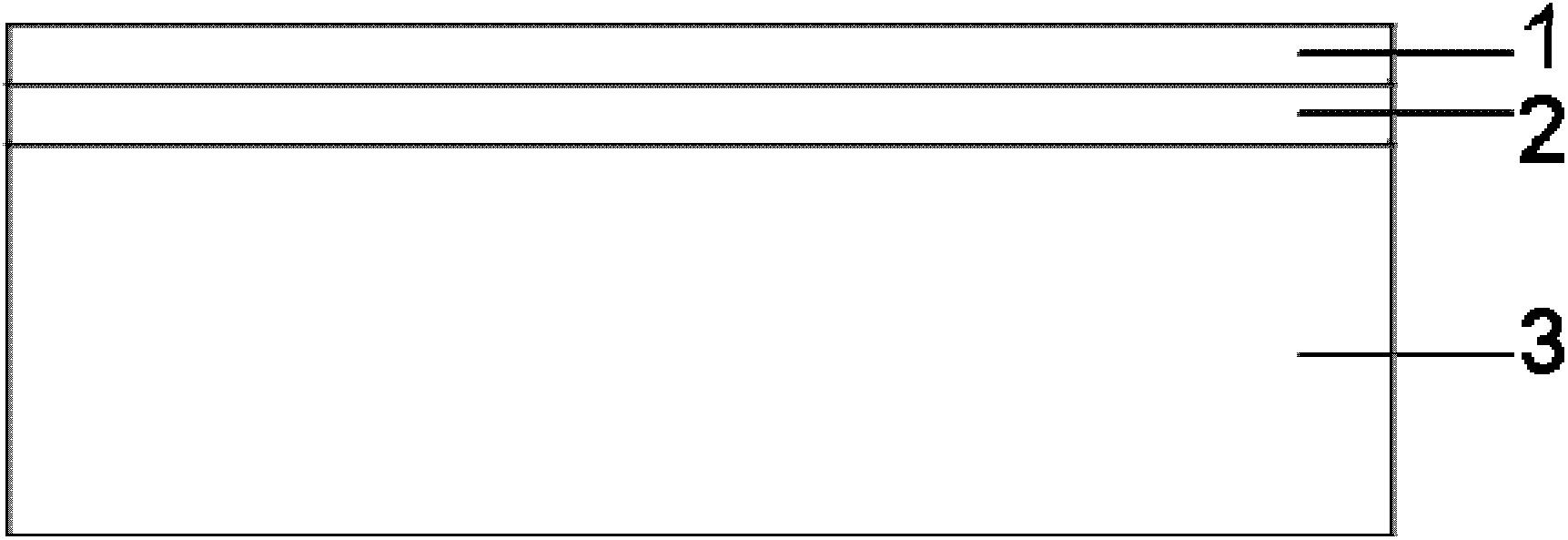

[0038] The schematic diagram of its product structure is shown in figure 1 As shown, a layer of ...

Embodiment 2

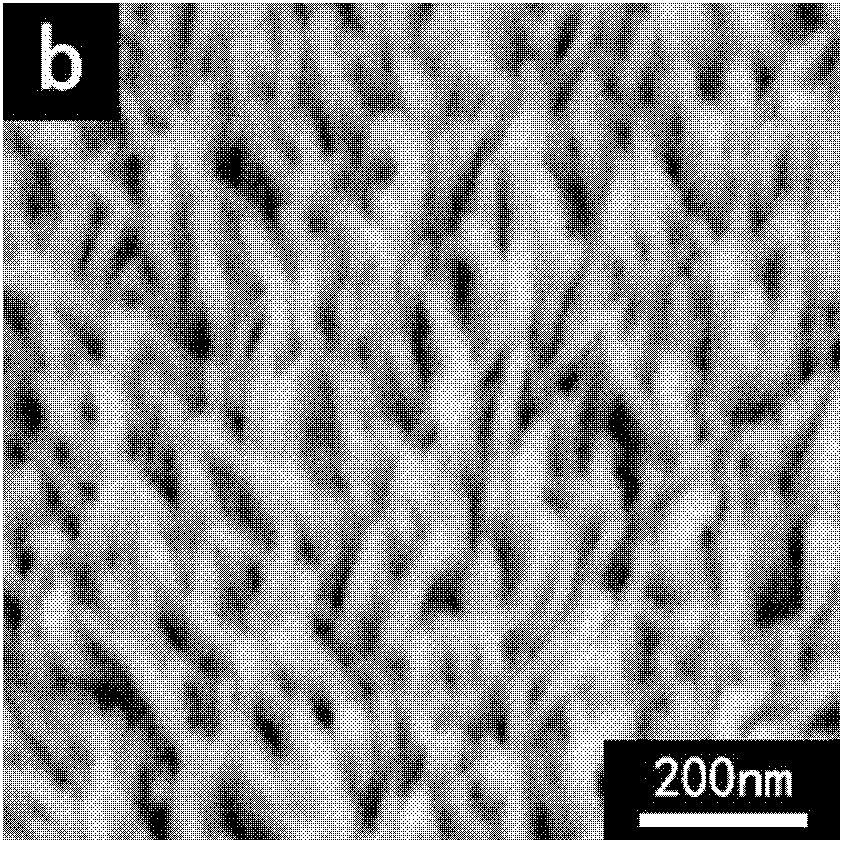

[0040] Disperse titanium dioxide nanoparticles with a particle diameter of 60-80nm in water to form a solution with a volume concentration of 0.5% of titanium dioxide nanoparticles; uniformly dispersed on the light-receiving surface of the polycrystalline silicon solar cell; finally, the polycrystalline silicon solar cell coated with titanium dioxide nanoparticles is naturally air-dried in the air.

[0041] The composition and structure of the product obtained above were characterized, and it can be seen from the XRD spectrum and scanning electron microscope photos that a layer of titanium dioxide nanoparticles with particle diameters of 60-80 nm grows on the light-receiving surface of the polycrystalline silicon solar cell.

Embodiment 3

[0043] Disperse tin dioxide nanoparticles with a particle diameter of 60-80nm in water to form a solution with a volume concentration of 0.5% tin dioxide nanoparticles; then apply the solution by spin coating at a speed of 350rad / min Cover the light-receiving surface of the thin-film solar cell, so that the tin dioxide nanoparticles are uniformly dispersed on the light-receiving surface of the thin-film solar cell; finally, the thin-film solar cell coated with the tin dioxide nano-particle is naturally air-dried in the air.

[0044]The composition and structure of the product obtained above were characterized, and it can be seen from the XRD spectrum and scanning electron microscope photos that a layer of tin dioxide nanoparticles with a particle diameter distribution of 60-80 nm grows on the light-receiving surface of the thin-film solar cell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com