A kind of activated carbon for recovering gasoline evaporation by using broad-leaved forest sawdust and its production method

A production method and broad-leaved forest technology, applied in the field of activated carbon, can solve the problems of waste, increased production costs, high rosin content, etc., and achieve the effects of stable product quality, reduced production costs, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

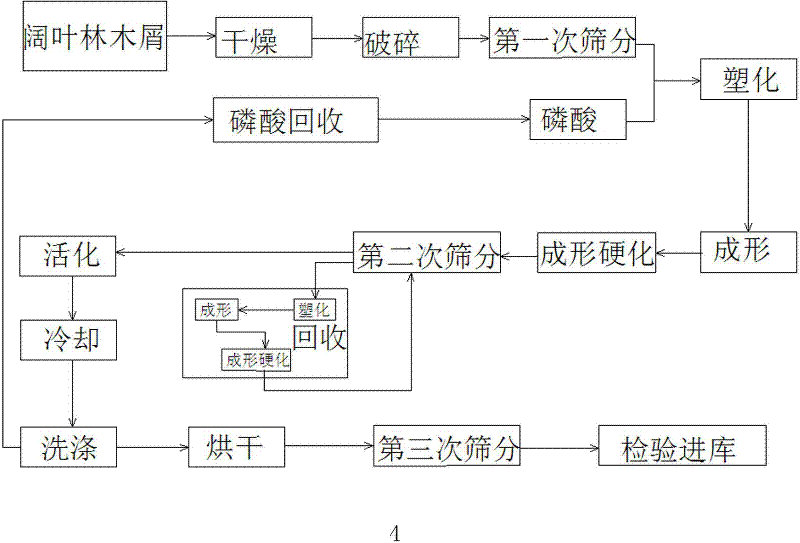

[0063] Dry the broad-leaved forest sawdust at a temperature of 110°C for 2.5 hours, then crush it into wood powder, and then sieve the crushed wood powder, and the particle range between (10-80) mesh is 98% . Mix the wood powder with the prepared phosphoric acid Baumé 50°Be’~60°Be’ in the ratio of 1:1.2 and pour it into the plasticizing furnace for plasticization.

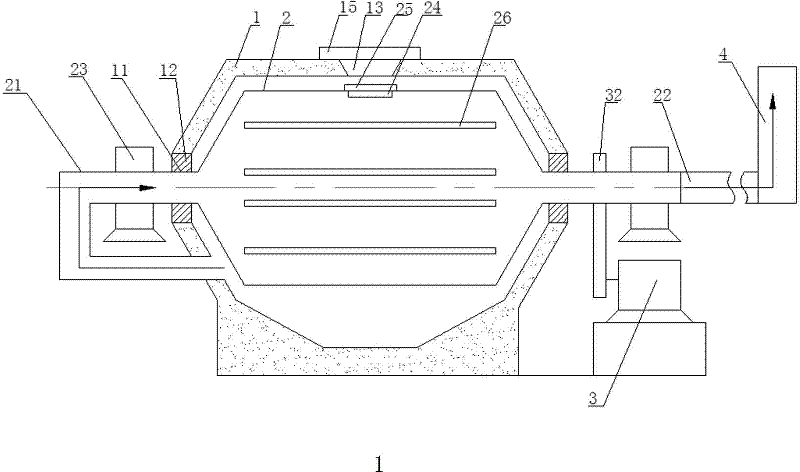

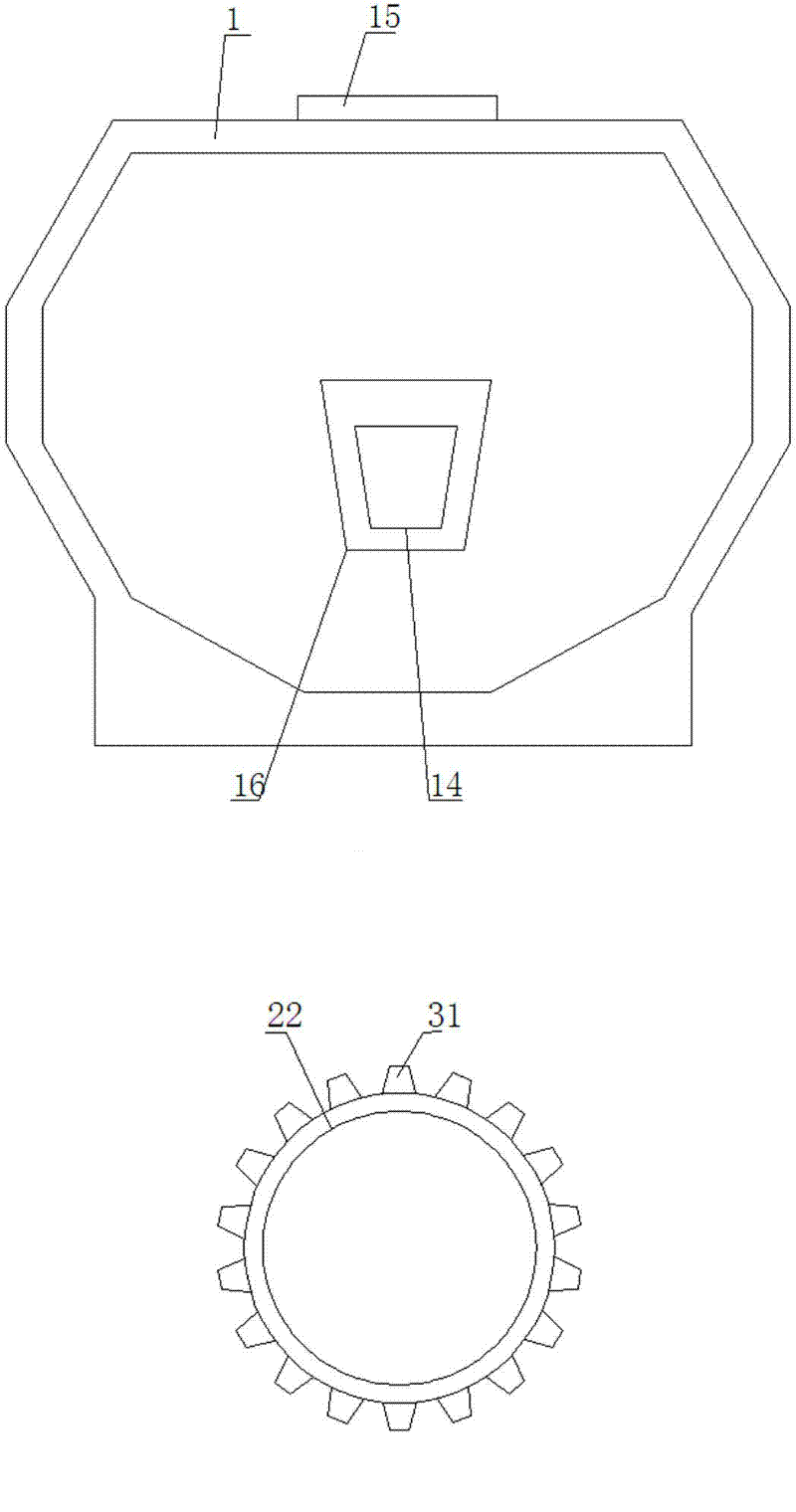

[0064] The interlayer temperature of the melting furnace is 150-220°C, and the plasticizing time is 1.5 hours. The plasticized charcoal is put into the forming machine to form a spherical shape, and then the formed spherical charcoal or columnar charcoal is formed and hardened. The temperature of the first zone of forming and hardening is 250°C for 2 hours; the temperature of the second zone is 250°C for 6 hours. After forming and hardening, the second screening is carried out. After the second screening, the qualified product (carbon material) enters the "olive" type converter for activation. The pre-activation t...

example 2

[0071] Dry the broad-leaved forest sawdust at a temperature of 130°C for 1 hour, then crush it into wood powder, and then sieve the crushed wood powder for the first time, and the particles are in the range of (10-80) mesh 97%. Mix the wood powder with the prepared phosphoric acid Baume degree 50°Be'~60°Be' in the ratio of 1:1.2 and pour it into the plasticizing furnace for plasticization. The interlayer temperature of the plasticizing furnace is 220°C and the plasticizing time is After 1.5 hours, put the plasticized carbon material into the forming machine to form a spherical shape, and then shape and harden the formed spherical carbon or columnar carbon. The temperature in the first area of forming hardening is 180°C for 5 hours; the temperature in the second area is 350°C , time 4 hours. After forming and hardening, the second screening is carried out. After the second screening, the qualified product (carbon material) enters the "olive" type converter for activation. Th...

example 3

[0078] Dry the broad-leaved forest sawdust at a temperature of 110°C for 3 hours, then crush it into wood powder, and then sieve the crushed wood powder for the first time, and the particles are in the range of (10-80) mesh 97%. Mix the wood powder with the prepared phosphoric acid Baume degree 50°Be'~60°Be' in the ratio of 1:1.2 and pour it into the plasticizing furnace for plasticization. The interlayer temperature of the plasticizing furnace is 240°C and the plasticizing time is After 2 hours, put the plasticized carbon material into the forming machine to form a spherical shape, and then shape and harden the formed spherical carbon or columnar carbon. The temperature in the first zone of forming hardening is 190°C, and the time is 4.5 hours; the temperature in the second zone is 280°C , time 5 hours. After forming and hardening, the second screening is carried out. After the second screening, the qualified product (carbon material) enters the "olive" type converter for ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com