Corrosion inhibitor for gas dehydration glycol regeneration unit in gas field

A regenerative device and ethylene glycol technology, which is applied in corrosion inhibition of gas production equipment and gas production in oil and gas fields, can solve problems such as corrosion and perforation of regeneration towers, and achieve the effects of prolonging life, accelerating dehydration speed and low chemical degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

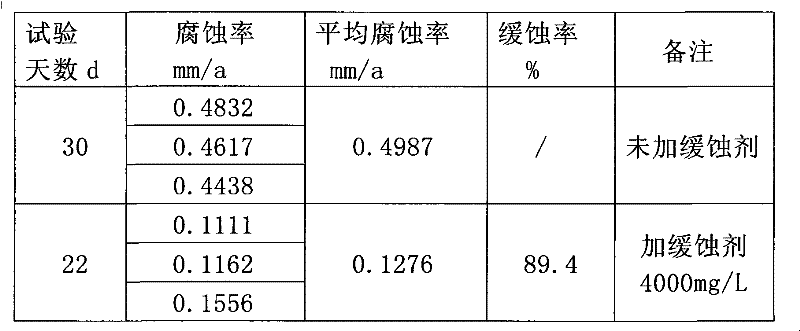

[0018] Example 1: Preparation of composite corrosion inhibitor for gas field gas dehydration ethylene glycol regeneration unit: at room temperature, add each component into the reactor by weight, stir for 45 minutes, and stir evenly; the weight of each component is: 12 0.5 part of alkyl hydroxyethyl imidazoline, 0.1 part of methyl pentynol; 0.2 part of hydroxyethylidene diphosphonic acid, 16 parts of triethanolamine, 0.5 part of Mannich base, 0.1 part of dehydroascorbic acid; Hydroquinone 0.03 part. The hanging plate experiment was carried out indoors, and the experimental results are as follows:

[0019] Indoor experiment effect table

[0020] dosage

Embodiment 2

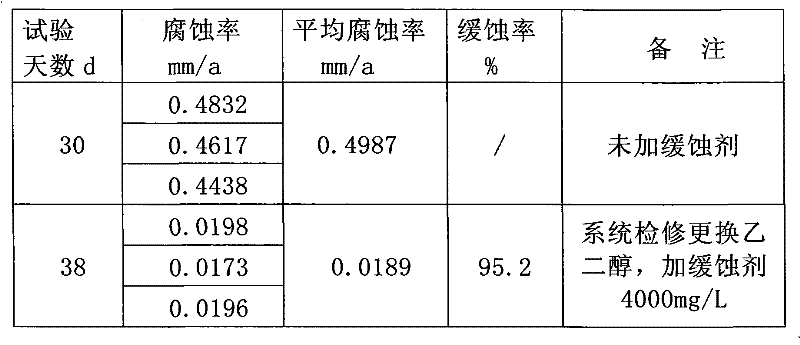

[0021] Example 2: The preparation of the composite corrosion inhibitor for the gas field gas dehydration glycol regeneration unit is the same as that in Example 1. The parts by weight of each component are: 0.45 parts of cycloalkyl KLSS-A imidazoline; 0.13 parts of methylpentynol; 0.3 parts, 18 parts of triethanolamine, 0.35 parts of Mannich base, 0.12 parts of dehydroascorbic acid; 0.06 parts of tert-butyl hydroquinone. Use: Add at the inlet of the ethylene glycol aqueous solution of the ethylene glycol dehydration regeneration equipment; detect the pH value of the liquid in the ethylene glycol rich liquid tank; etchant. Glycol dehydration speed increased by 20%. The on-site use effect is as follows:

[0022] On-site use effect table

[0023]

Embodiment 3

[0024] Example 3: The method of preparation and use of the composite corrosion inhibitor for gas field gas dehydration glycol regeneration unit is the same as that of Example 2. The parts by weight of each component are: 0.55 parts of carboxymethyl amphoteric imidazoline; 0.14 parts of methylpentynol; 0.45 parts of hydroxyethylidene diphosphonic acid, 17 parts of triethanolamine, 0.45 parts of Mannich base, and 0.14 parts of dehydroascorbic acid Parts; 0.09 parts of tert-butyl hydroquinone. Glycol dehydration speed increased by 22%.

[0025] On-site use effect table

[0026]

[0027] After 9 months of field tests, it has been proved that the ethylene glycol regeneration equipment is in stable operation, has no effect on the performance of ethylene glycol, has no side effects on the operation of reboilers, regeneration towers and other equipment, and can control the corrosion of ethylene glycol regeneration equipment to within 0.20mm / a or less; after equipment maintenance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com