A Rotary Microwave Vacuum Dryer

A microwave vacuum drying and rotary technology, used in non-progressive dryers, dryers, drying solid materials, etc., can solve the problem that the solvent needs to be recovered or the system containing strong irritating toxic gases cannot be realized, and the material container cannot be pumped. Vacuum, material can not be granulated and other problems, to achieve the effect of shortening drying time, fast solvent evaporation, and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

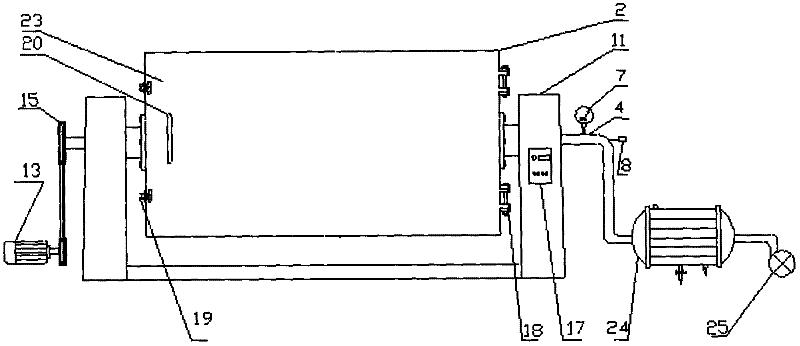

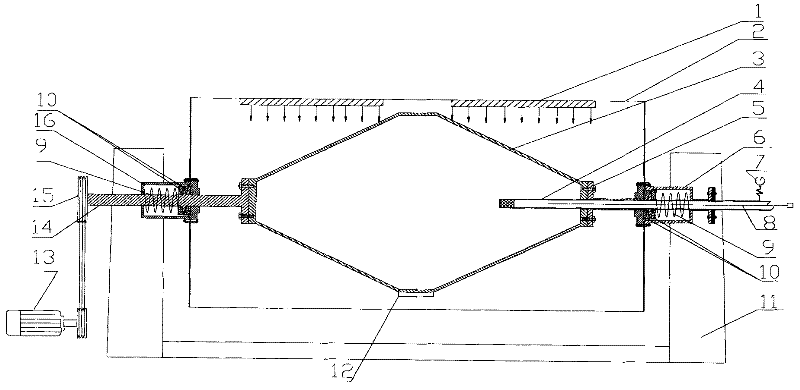

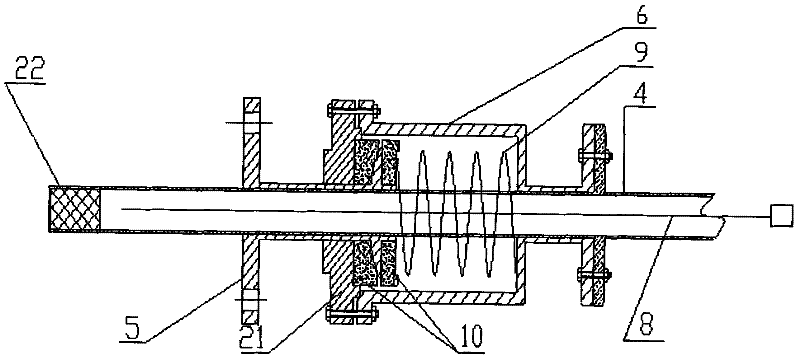

[0017] The specific embodiment: below in conjunction with accompanying drawing, the best embodiment of the present invention is described in detail:

Embodiment

[0018] Embodiment: a kind of rotary microwave vacuum drier (see Figure 1-Figure 3 ), which includes a bracket 11, an operation panel 17 is provided on the bracket 11, a microwave oven body 2 is connected between the brackets 11, a microwave generator 1 is arranged at the upper end of the microwave oven body 2, and one end of the oven door 23 is connected to the microwave oven body 2 through a door hinge 18 , the other end of the oven door 23 is connected with the microwave oven body 2 through the lock nut 19, the oven door 23 is provided with an oven door handle 20, and the microwave oven body 2 is provided with a double-cone rotary material cavity 3, and the double-cone rotary container The material cavity 3 has a built-in vacuum filter tube 4 with a filter head 22. One end of the double-cone rotary material cavity 3 is connected to the vacuum filter tube 4 through a hollow shaft 5 with a flange, and the vacuum filter tube 4 is connected to condensation recovery. 24, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com