Full-bridge rectification-DC push-pull inverter ac-dc converter

An AC-DC, DC push-pull technology, applied in the direction of converting DC power input to DC power output, AC power input converting to DC power output, and irreversible AC power input converting to DC power output, etc. It can solve the problem of low feasibility. , high control difficulty, complex structure and other problems, to achieve the effect of economical and practical, simplified circuit structure, small system volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

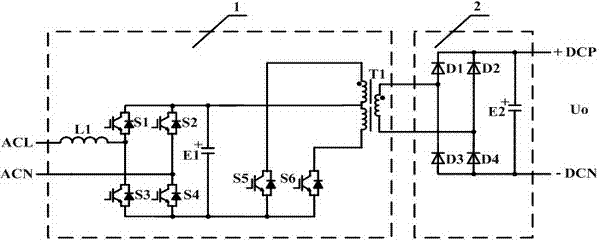

[0025] like figure 1 As shown, this embodiment provides a full-bridge rectification-DC push-pull inverter AC-DC converter, including: step-down circuit 1 and a rectifier circuit 2 connected thereto, wherein: step-down circuit 1 Convert high-voltage power frequency AC voltage into low-voltage high-frequency AC voltage. In the rectifier circuit 2, the low-voltage high-frequency AC voltage is converted into a low-voltage DC voltage, and the impedance conversion circuit can be connected in series in the subsequent stage to obtain linear input impedance and linear grid-side impedance to ensure a good grid-side power factor.

[0026] The step-down circuit 1 includes a sequentially connected boost inductor L1, a single-phase input rectifier (shown as S1 to S4 in the figure), an input filter capacitor E1, and a push-pull converter for AC chopping (S5 and S6 in the figure). shown) and high-frequency transformer T1 for step-down.

[0027] The boost inductor L1 used in the step-down ...

Embodiment 2

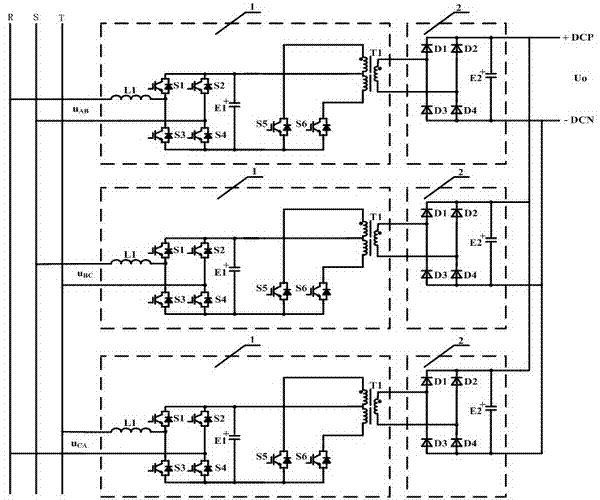

[0038] like figure 2 As shown, a schematic diagram of a three-phase input and output parallel full-bridge rectifier-DC push-pull inverter AC-DC converter. each of them Full-bridge rectification-DC push-pull inverter AC-DC converter The input terminals of the three-phase alternating current are respectively connected to any two phases, the three groups Full-bridge rectification-DC push-pull inverter AC-DC converter The output terminals are connected in parallel and output DC voltage.

[0039] This embodiment can avoid excitation saturation of the transformer and support greater power output.

Embodiment 3

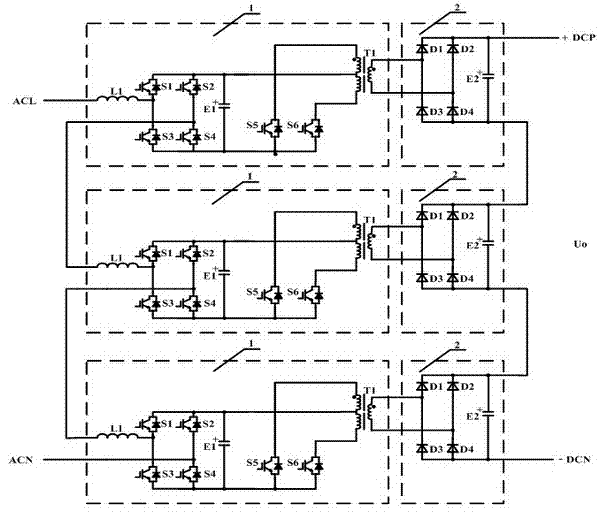

[0041] like image 3 As shown, a schematic diagram of an AC-DC converter with a full-bridge rectifier-DC push-pull inverter in series with input and output in series. consists of three groups of the same structure Full-bridge rectification-DC push-pull inverter AC-DC converter Composition, the three groups Full-bridge rectification-DC push-pull inverter AC-DC converter The input ends are connected in series, and the output ends are connected in series to output DC voltage.

[0042] This embodiment can avoid excitation saturation of the transformer, and realize high voltage input and greater power output.

[0043] After the device adopts the step-down circuit and the rectifier circuit, it can make the grid side of the power electronic converter work at the unit power factor without the need of the rear-stage series impedance conversion circuit, and eliminate the pollution of the harmonic current to the grid, which is conducive to simplifying the circuit design. , redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com