Preparation method of pesticide solvent replacing petroleum aromatic hydrocarbon solvent

A technology of aromatic solvents and pesticides, applied in the field of preparation of pesticide solvents, can solve the problems of processing, storage and transportation, aggravating the shortage of oil resources, unfavorable resource utilization, etc., to ensure social and food safety, strong wettability and permeability , Improve the effect of the drug effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

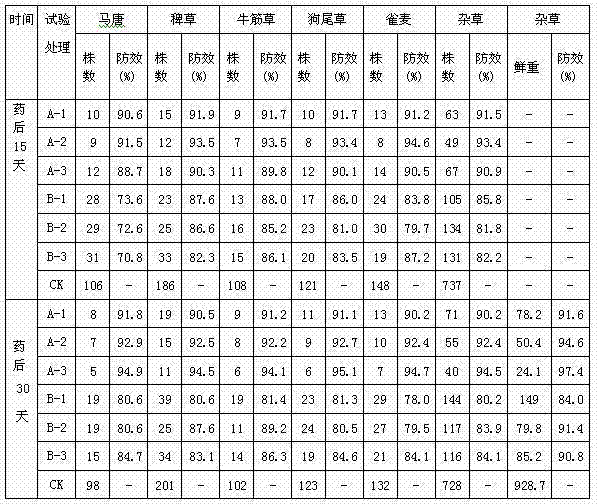

Image

Examples

Embodiment 1

[0043] (1) Filtration: It is carried out using conventional filtering equipment and processes known in the industry. Recover the waste oil, remove the solid impurities, mechanical suspended matter and part of the peptized substances contained in the waste oil.

[0044] (2) Acidification: Put the filtered waste oil and concentrated sulfuric acid with a mass concentration of 98% into the reaction vessel according to the mass ratio of 1:1, stir, heat to 105°C, and keep it warm for 1 hour, then stop stirring and let stand 1.5h, release the lower layer of acid solution, wash the upper layer of fat with water to a pH value of 4~5, heat to 250°C under a vacuum of 60mmHg and stir for 1h for dehydration.

[0045] (3) Esterification: Put the fatty matter and n-octanol treated in step (2) into the reaction kettle at a weight ratio of 6:1, then add concentrated sulfuric acid with a mass concentration of 98%, and heat under stirring Reflux for 15 hours, then distill off the n-octanol and ...

Embodiment 2

[0053] (1) Filtering: Instance 1 at the same time.

[0054] (2) Acidification: Put the filtered waste oil and concentrated sulfuric acid with a mass concentration of 80% into the reaction vessel according to the mass ratio of 1:8, stir and heat to 80°C, keep it warm for 3 hours, and then let it stand for 1 hour. Release the acid solution in the lower layer, wash the fat in the upper layer with water to a pH value of 4~5, heat to 120°C under a vacuum of 55 mmHg and stir for 3 hours for dehydration.

[0055] (3) Esterification: Put the fatty matter and n-octanol treated in step (2) into the reaction kettle at a weight ratio of 8:1, then add concentrated sulfuric acid with a mass concentration of 98%, and heat under stirring Reflux for 12 hours, then distill off the n-octanol, stop heating at 110°C to obtain the initial ester of the fatty substance, and the mass of the concentrated sulfuric acid is 5% of the total mass of the above-mentioned fatty substance and n-octanol.

[005...

Embodiment 3

[0063] (1) Filtering: Instance 1 at the same time.

[0064] (2) Acidification: Put the filtered waste oil and concentrated sulfuric acid with a mass concentration of 98% into the reaction vessel at a mass ratio of 9:1, stir, heat to 120°C, keep warm for 0.5h, and then stand for 3h , release the acid solution in the lower layer, wash the fatty matter in the upper layer with water to a pH value of 4~5, heat to 290~300°C under a vacuum of 55mmHg and stir for 0.5h for dehydration.

[0065] (3) Esterification: Put the fat and n-octanol after the treatment in step (2) into the reaction kettle at a weight ratio of 10:1, then add concentrated sulfuric acid with a mass concentration of 98%, and heat under stirring Reflux for 16 hours, then distill off the n-octanol, stop heating at 110°C to obtain the initial ester of the fatty substance, and the mass of the concentrated sulfuric acid is 3% of the total mass of the above-mentioned fatty substance and n-octanol.

[0066] (4) Deacidific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com