A kind of industrial wastewater treatment process

A technology of industrial waste water and treatment process, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of increasing tap water usage, unfavorable full utilization of resources, and failure to comply with circular economy and other issues, to achieve a wide range of uses, good economic and environmental benefits, and the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

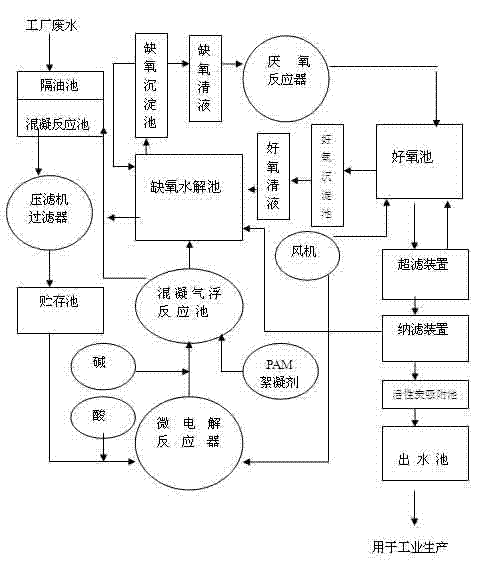

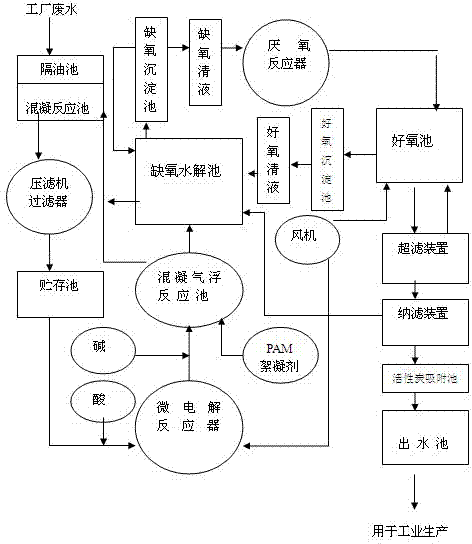

[0016] A kind of industrial wastewater treatment process, see figure 1 , the process includes the following steps:

[0017] 1) The industrial wastewater to be treated enters the grease trap for oil separation treatment;

[0018] 2) The waste water after oil separation enters the coagulation reaction tank, and the flow device of the coagulation tank is opened to carry out the coagulation reaction;

[0019] 3) The waste water after the coagulation reaction is filtered and sent to the storage pool for use;

[0020] 4) The waste water from the storage pool enters the micro-electrolysis reactor, and the pH value of the water in the micro-electrolysis reactor is adjusted with acid, which is controlled between 3 and 4; the acid can be one of hydrochloric acid, nitric acid or a mixture thereof; Activated carbon and iron powder are added into the reactor, and the amount of activated carbon and iron powder is both 0.01%-0.03% of the total amount of wastewater. Activated carbon and ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com