A method of manufacturing a polarization-maintaining optical fiber

A polarization-maintaining optical fiber and prefabricated rod technology, which is applied in the direction of manufacturing tools, glass manufacturing equipment, glass fiber products, etc., can solve the problems of low yield, time-consuming, affecting the strength of optical fibers, etc., to increase the probability of bursting, reduce production costs, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

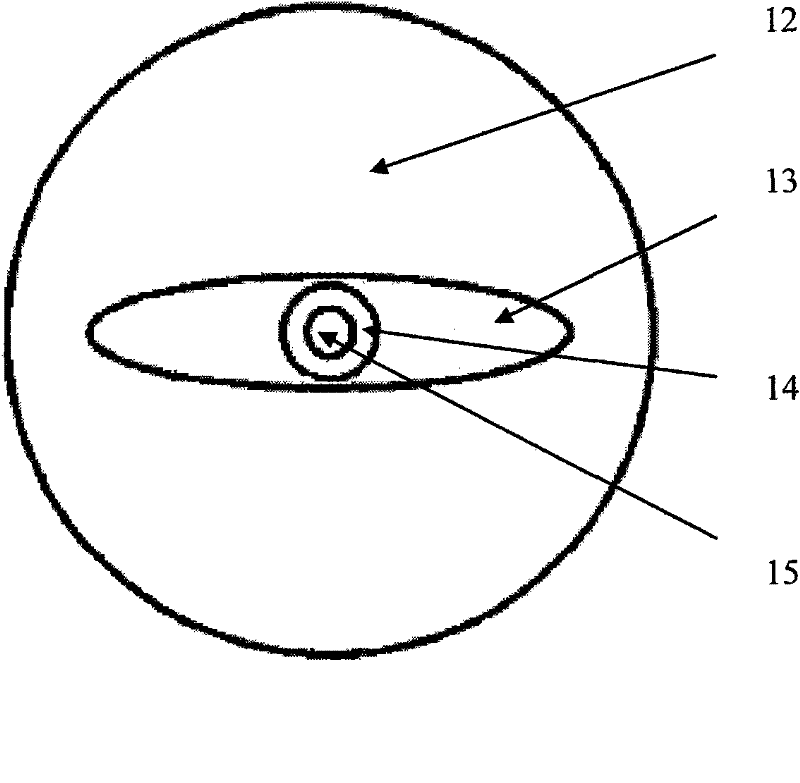

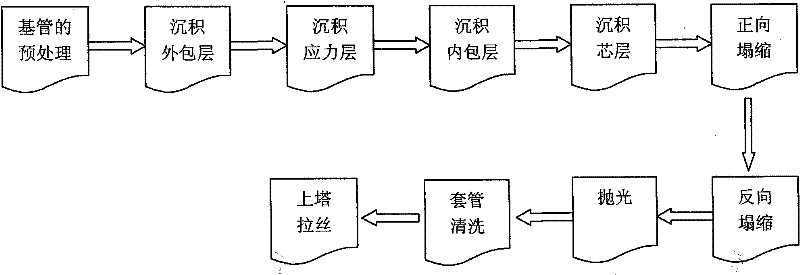

Embodiment 1

[0021] Embodiment 1: as figure 2 As shown, the pretreatment of the base tube, the deposition of the outer cladding layer, the deposition of the stress layer, the deposition of the inner cladding layer, the deposition of the core layer, the forward collapse, the reverse collapse, and the polishing process are carried out on the MCVD lathe to prepare the preform. Thinned into an optical fiber with a diameter of 40 μm, and coated with a light-cured coating on its periphery for protection, and the coating was cured by ultraviolet light to obtain an elliptical cladding polarization-maintaining optical fiber with a final coating diameter of 110 μm, and the ellipticity of the stress region is 2.8:1 , the main technical indicators of the elliptical cladding polarization maintaining fiber are shown in Table 1.

Embodiment 2

[0022] Embodiment 2: as figure 2 As shown, the pretreatment of the base tube, the deposition of the outer cladding layer, the deposition of the stress layer, the deposition of the inner cladding layer, the deposition of the core layer, the forward collapse, the reverse collapse, and the polishing process are carried out on the MCVD lathe to prepare the preform. Thinned into an optical fiber with a diameter of 40 μm, and coated with a light-cured coating on its periphery for protection, and the coating was cured by ultraviolet light to obtain an elliptical cladding polarization-maintaining optical fiber with a final coating diameter of 11 μm, and the ellipticity of the stress zone is 2.7:1 , the main technical indicators of the elliptical cladding polarization maintaining fiber are shown in Table 1.

[0023] Table 1 Main technical indicators of elliptical cladding polarization maintaining fiber

[0024] Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com