A new type of water-based rust inhibitor

A technology of water-based anti-rust agent and anti-rust additive, applied in the field of anti-corrosion of metal materials, can solve the problems of precipitation, affecting operation, high price, and achieve the effects of convenient use, inhibiting corruption, and eliminating the cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

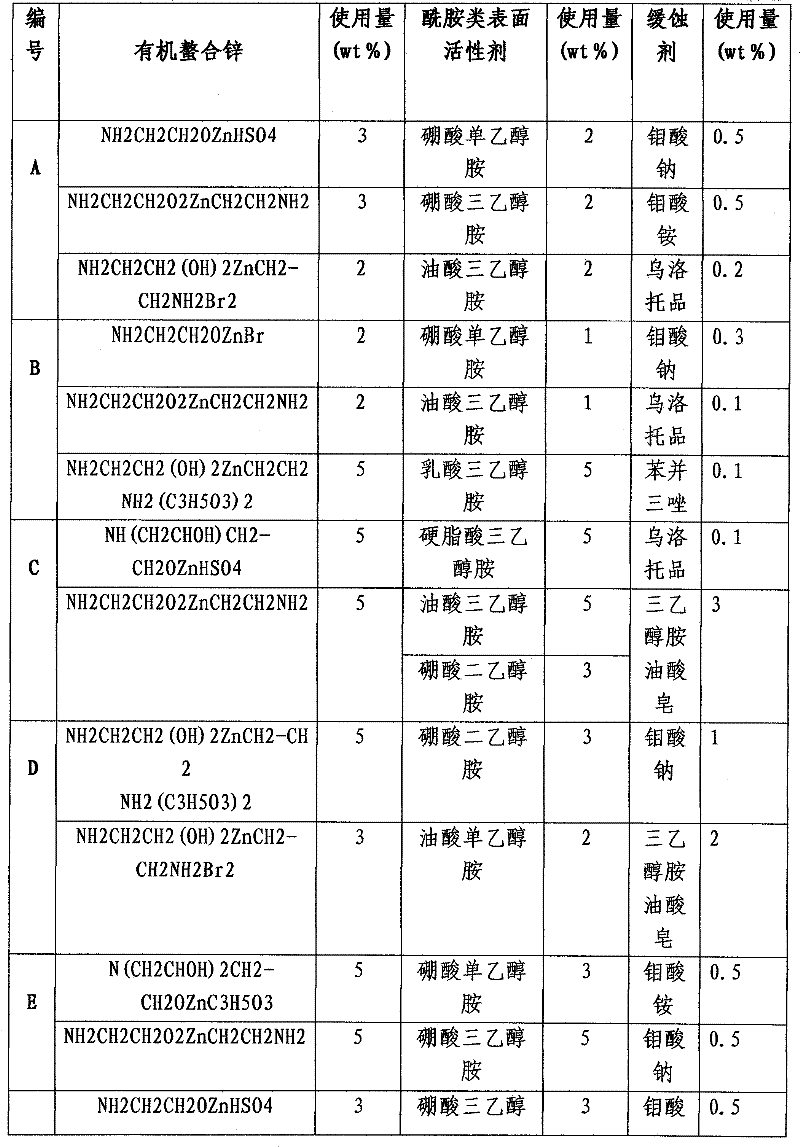

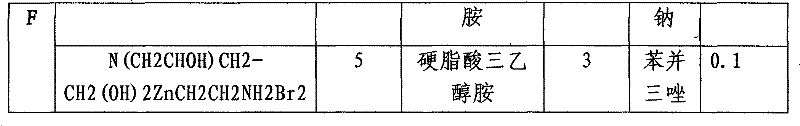

Method used

Image

Examples

Embodiment Construction

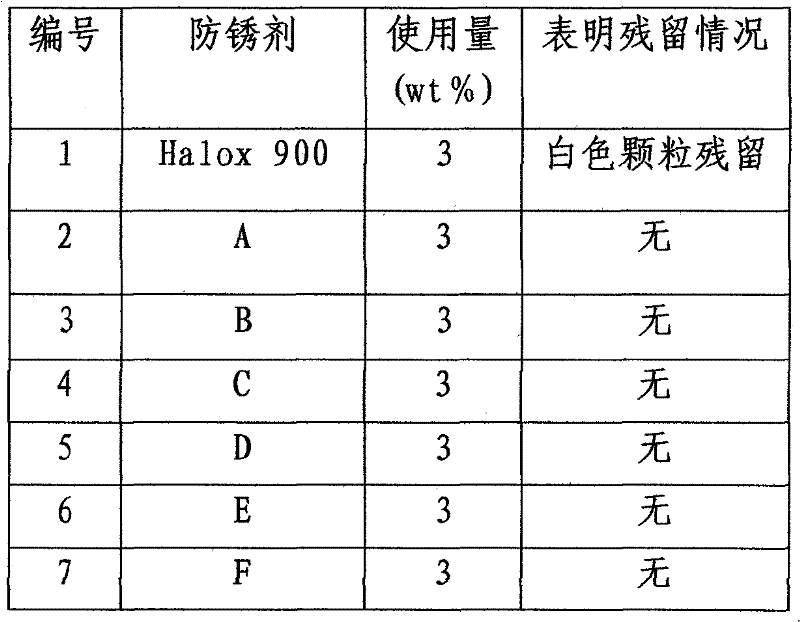

[0030] Metalworking fluids such as metal cutting fluids, grinding fluids, and cleaning agents have similar requirements for water-based antirust agents. Therefore, the antirust effect of 45 steel and chrome steel is tested on the spot when using this antirust agent alone or when it is added to the cleaning agent. Experiment; the advantages of this antirust agent are demonstrated by comparing with the product halox 900 of the American halox company in the residual test, salt spray test and indoor coupon test.

[0031] The water-based cleaning agent is formulated as fatty alcohol polyoxyethylene ether 15WT15%, builder 10%. In the field experiment, the amount of antirust agent added to the cleaning agent was 8%. After the antirust agent is added to the cleaning agent, it needs to be fully stirred until it is uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com