Machining process of assembly type aluminum alloy door and window profile

A technology of aluminum alloy doors and windows and processing technology, which is applied in the field of doors and windows, can solve the problems of poor corrosion resistance and oxidation resistance of the antirust layer, affecting the service life of aluminum alloy doors and windows profiles, complex equipment, etc., to achieve automatic work and convenient installation and disassembly, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

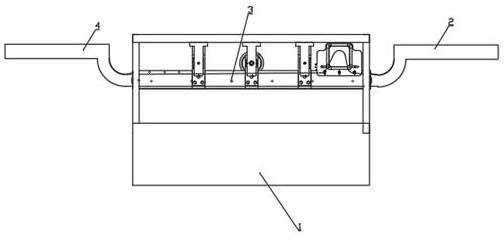

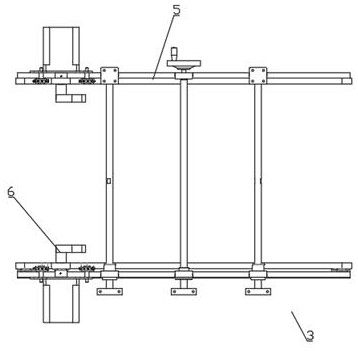

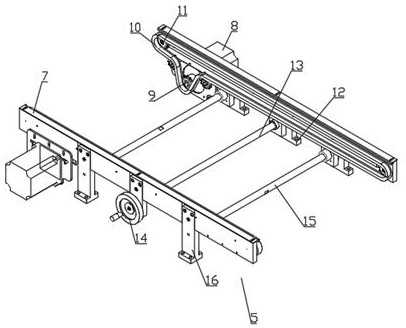

[0033] see Figure 1-3 As shown, a processing technology of assembled aluminum alloy door and window profiles includes the following steps:

[0034] The first step: put the anti-rust liquid into the soaking box 1; then control the rotation of the turntable 14 according to the length of the aluminum alloy door and window profiles, and drive the screw rod 13 to rotate, so that a group of transmission mounting plates 7 can be rotated along the limit Position slide bar 15 moves, adjusts the spacing between two groups of transmission mounting plates 7;

[0035] Step 2: Hang the aluminum alloy door and window profile on the feeding conveyor frame 2 through the hook 6, then start the drive motor 8 to work, drive the driving chain wheel 9 to work, and the driving chain wheel 9 rotates, so that the conveyor chain 10 moves along the upper The material conveying frame 2 and the unloading conveying frame 4 are conveyed, and the aluminum alloy doors and windows profiles are conveyed along t...

Embodiment 2

[0048] Compared with Example 1, the difference is:

[0049] The antirust solution is composed of the following raw materials in parts by weight: 12 parts of sodium molybdate, 9 parts of sodium silicate, 6 parts of sodium nitrate, 2 parts of surfactant, 1 part of thickener, 75 parts of deionized water, 12 parts of preservative, Antioxidant 10 parts.

[0050] The preparation process of antirust liquid comprises the following steps: mixing sodium molybdate, sodium silicate, sodium nitrate, surfactant, thickener, deionized water, preservative and antioxidant, and under the condition of temperature 100 ℃ After ultrasonic dispersion for 4 hours, the antirust solution was obtained.

[0051] The preparation technology of preservative comprises the following steps:

[0052] The first step: mix hexagonal boron nitride, sodium carbonate solution with a mass fraction of 2%, and ethanol, and ultrasonically disperse it for 20 minutes, then add dopamine hydrochloride for mixing, and stir a...

Embodiment 3

[0057] Compared with Example 1, the difference is:

[0058] The antirust liquid is composed of the following raw materials in parts by weight: 15 parts of sodium molybdate, 10 parts of sodium silicate, 7 parts of sodium nitrate, 2 parts of surfactant, 2 parts of thickener, 80 parts of deionized water, 15 parts of preservative, Antioxidant 8-12 parts.

[0059] The preparation process of antirust liquid comprises the following steps: mixing sodium molybdate, sodium silicate, sodium nitrate, surfactant, thickener, deionized water, preservative and antioxidant, and under the condition of temperature 100 ℃ After ultrasonic dispersion for 4 hours, the antirust solution was obtained.

[0060] The preparation technology of preservative comprises the following steps:

[0061] The first step: mix hexagonal boron nitride, sodium carbonate solution with a mass fraction of 2%, and ethanol, and ultrasonically disperse it for 20 minutes, then add dopamine hydrochloride for mixing, and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com