A Fully Differential Capacitance Readout Circuit with Cross Sampling and Double Summing of Charges

A capacitive readout and fully differential technology, which is applied in the direction of measuring devices, instruments, steering sensing equipment, etc., can solve the problems of increasing system area and power consumption, complicating temperature compensation circuits and methods, etc., to eliminate common-mode voltage drift, increase Large system dynamic range, the effect of suppressing mistuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

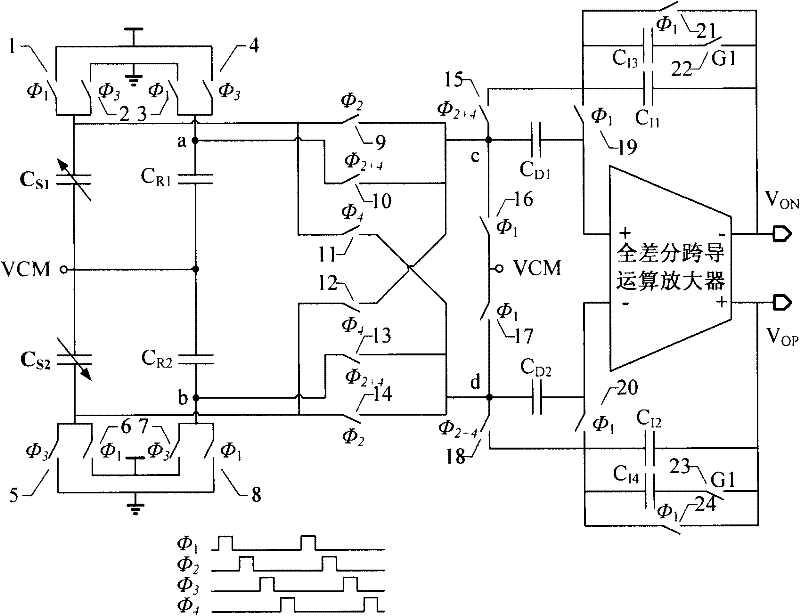

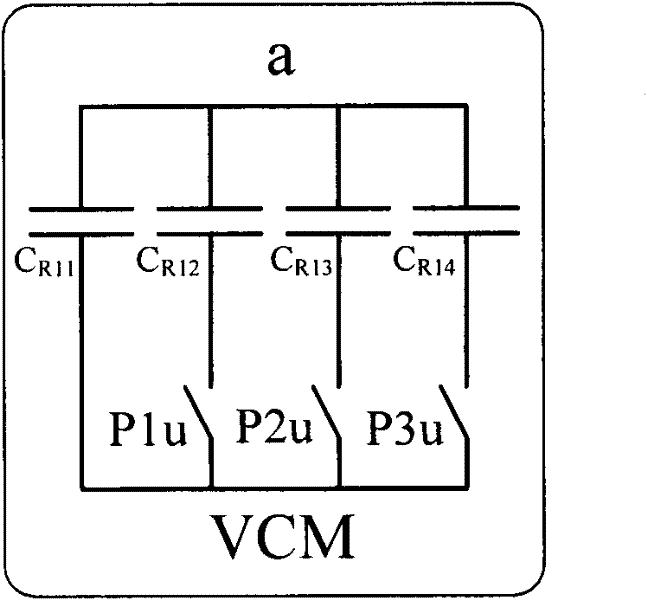

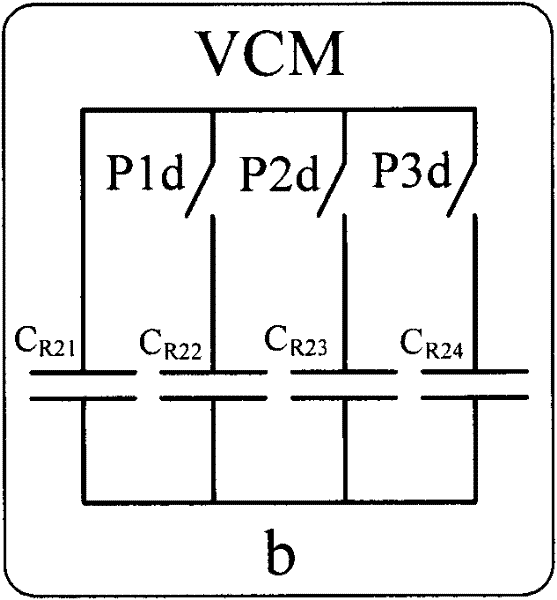

[0040]The present invention is oriented to capacitance sensors with differential structures such as micro-gyroscopes and micro-accelerometers. Aiming at the characteristics of weak output signals of micro-sensors, a fully differential weak capacitance readout circuit with cross sampling charge secondary summation is proposed. The circuit adopts switch Capacitive circuit implementation, insensitive to parasitic capacitance, suppressing circuit offset and low-frequency 1 / f noise through related double-sampling capacitors to improve capacitance resolution; using reference capacitors to reduce sensor capacitance mismatch and improve system dynamics range; fixed common-mode voltage, eliminates the impact of the mismatch of the reference capacitor in the readout circuit by means of the second summation of charges, and fixes the reference capacitor array (C R1 =C R2 ), which can eliminate the impact of common-mode voltage drift.

[0041] The cross-sampling charge quadratic summation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com