Method for preparing polystyrene maleimide membrane for gasoline desulfurization by pervaporation

A technology of maleimide membrane and maleimide, applied in dialysis purification, chemical instruments and methods, semi-permeable membrane separation, etc., can solve the problems of no advantages, large energy, consumption, etc., and achieve cost Inexpensive, simple synthesis steps, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of the present embodiment is realized like this, comprises the following steps:

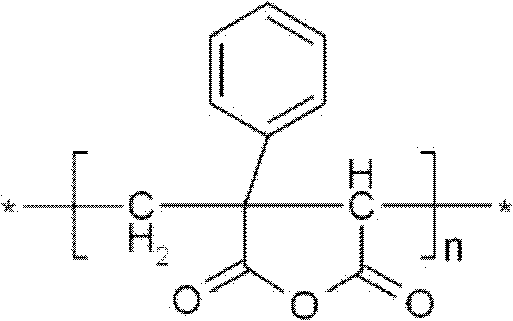

[0039] Step 1: Preparation of polystyrene maleic anhydride copolymer (SMA)

[0040] Dissolve maleic anhydride in toluene at room temperature; after fully dissolving, add initiator benzoyl peroxide (BPO) and styrene; heat in a water bath at 60°C, react for 2 hours, filter the resulting precipitate, and wash; at 80°C Vacuum dried to obtain polystyrene maleic anhydride copolymer (SMA). The mass percentages of the above raw materials are as follows: maleic anhydride accounts for 5%, toluene accounts for 80%, initiator benzoyl peroxide (BPO) accounts for 2%, and styrene accounts for 13%.

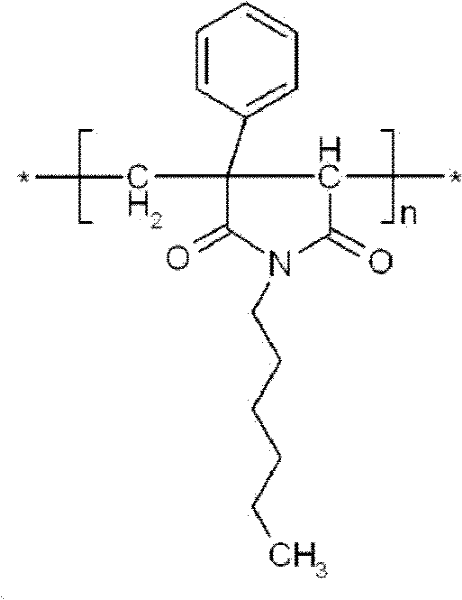

[0041] Step 2: Preparation of polystyrene maleimide (SMI) solid material

[0042]At room temperature, add the polystyrene maleic anhydride copolymer (SMA) prepared in step 1 and n-hexylamine for imidization into the reaction flask, and dissolve it with dimethylformamide; use an inert ...

Embodiment 2

[0048] The preparation technology of the present embodiment is realized in this way, comprises the following steps:

[0049] Step 1: Preparation of polystyrene maleic anhydride copolymer (SMA)

[0050] Dissolve maleic anhydride in toluene at room temperature; after fully dissolving, add initiator azobisisobutyronitrile (AIBN) and styrene; heat in a water bath at 70°C, react for 3 hours, filter the resulting precipitate, and wash; at 90°C Dry under vacuum to obtain polystyrene maleic anhydride copolymer (SMA). The mass percentages of the above substances are: maleic anhydride accounts for 7%, toluene accounts for 75%, initiator accounts for 1.5%, and styrene accounts for 16.5%.

[0051] Step 2: Preparation of polystyrene maleimide (SMI) solid material

[0052] At room temperature, in the reaction flask, add the polystyrene maleic anhydride copolymer (SMA) prepared in step 1, n-heptylamine for imidization, dissolve with dimethylformamide; use inert gas argon protection, Stir ...

Embodiment 3

[0058] The preparation method of the present embodiment is realized like this, comprises the following steps:

[0059] Step 1: Preparation of polystyrene maleic anhydride copolymer (SMA)

[0060] Dissolve maleic anhydride in toluene at room temperature; after fully dissolving, add initiator azobisisobutyrate dimethyl (AIBME) and styrene; heat in a water bath at 80°C, react for 5 hours, filter the resulting precipitate, and wash; Vacuum-dried at 100° C. to obtain polystyrene-maleic anhydride copolymer (SMA). The mass percentages of the above substances are: maleic anhydride accounts for 9%, toluene accounts for 70%, initiator azobisisobutyrate dimethyl (AIBME) accounts for 1%, and styrene accounts for 20%.

[0061] Step 2: Preparation of polystyrene maleimide (SMI) solid material

[0062] At room temperature, add the polystyrene maleic anhydride copolymer (SMA) prepared in step 1 and aniline for imidization to the reaction flask, and dissolve it with dimethylformamide; use in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com