Antioxidation slag removal agent for welding of metal materials

A technology of metal materials and slag removal agent, which is applied in the direction of welding medium, welding equipment, metal processing equipment, etc., can solve the problems of easy harm to human health, poor slag removal effect, unfavorable production and use, etc., to improve physical and chemical properties, improve Effect of mechanical strength and consumption saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

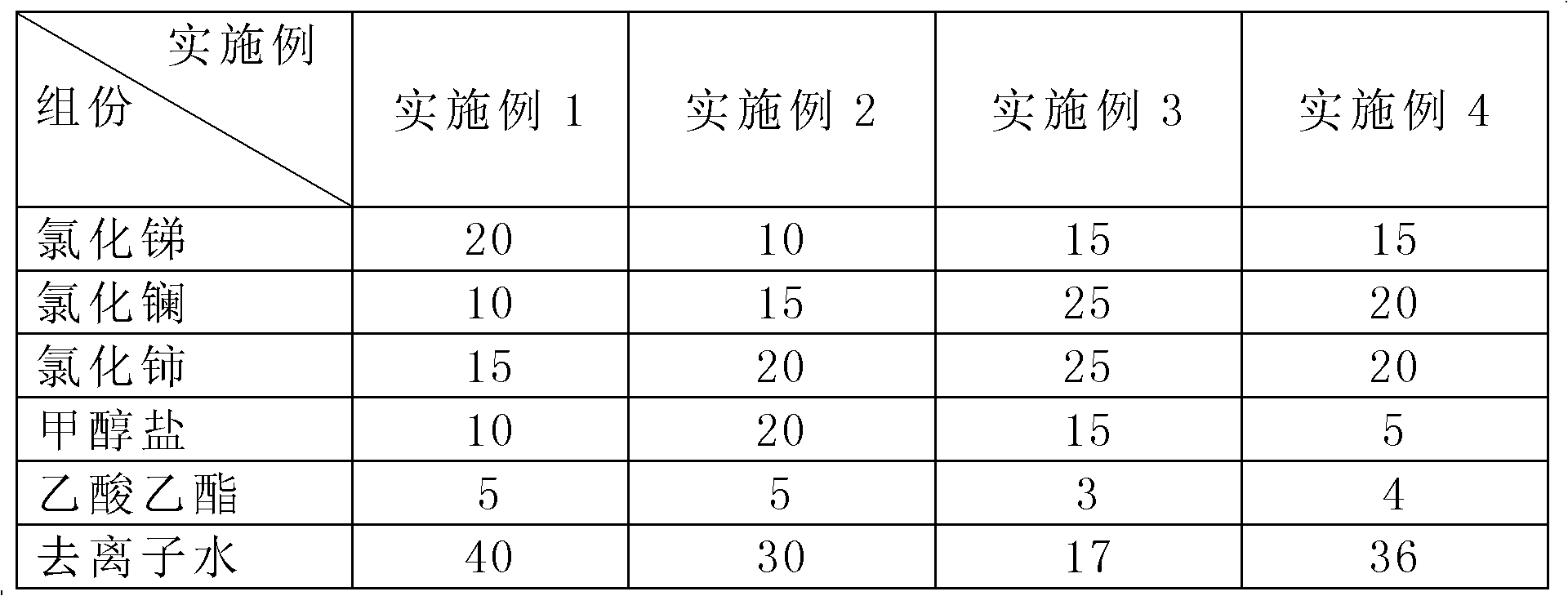

Embodiment 1

[0030] According to the mass percentage of each component in the above-mentioned Table 1 Example 1, the raw materials are selected, and after being configured into a solution, after stirring evenly, let stand for precipitation for 60 minutes, and after standing, pass the obtained solid matter through a 200-mesh stainless steel sieve, Put the sieved solid in a drying oven, control the temperature at 135°C, and dry for 60 minutes; put the dried solid in a grinder for grinding and crushing, and then pass through a 200-mesh sieve to obtain this product. The finished product of the slag removal agent invented can be packed in bags according to different specifications according to actual needs, and stored in a dry, dark, and ventilated manner.

Embodiment 2

[0032] According to the mass percentage of each component in the above-mentioned Table 1 Example 2, the raw materials are selected, and after being configured into a solution, after stirring evenly, let stand for precipitation for 60 minutes, and after standing, pass the obtained solid matter through a 250-mesh stainless steel sieve, Put the sieved solids in a drying oven, and dry them for 60 minutes at a controlled temperature of 125°C to 130°C; put the dried solids into a grinder for grinding and crushing, and pass through 250 mesh The finished product of the slag-removing agent of the present invention can be obtained; it can be packed in bags according to different specifications according to actual needs, and stored in a dry, light-proof and ventilated manner.

Embodiment 3

[0034] According to the mass percentage of each component in the above-mentioned Table 1 Example 3, the raw materials are selected, and the following specific steps are consistent with the method in Example 1, so they are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com