Senegenin derivative, as well as preparation method and application thereof

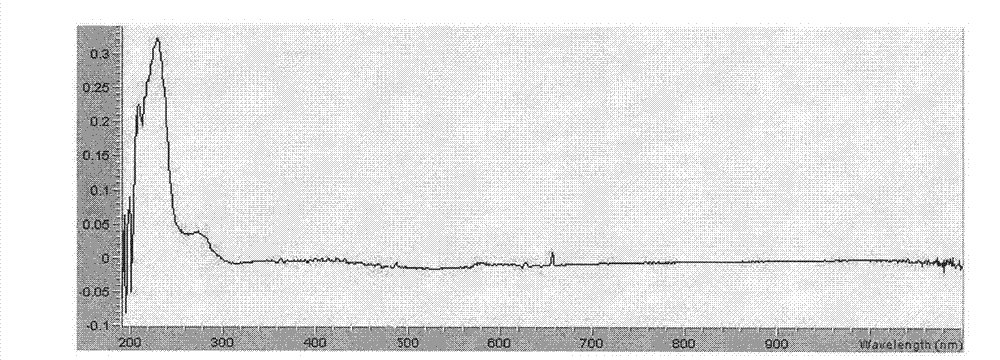

A polysapogenin and derivative technology, applied in steroids, measuring devices, instruments, etc., can solve the problems of large baseline drift, low sensitivity, solvent interference, etc., and achieve the effect of avoiding absorption detection defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

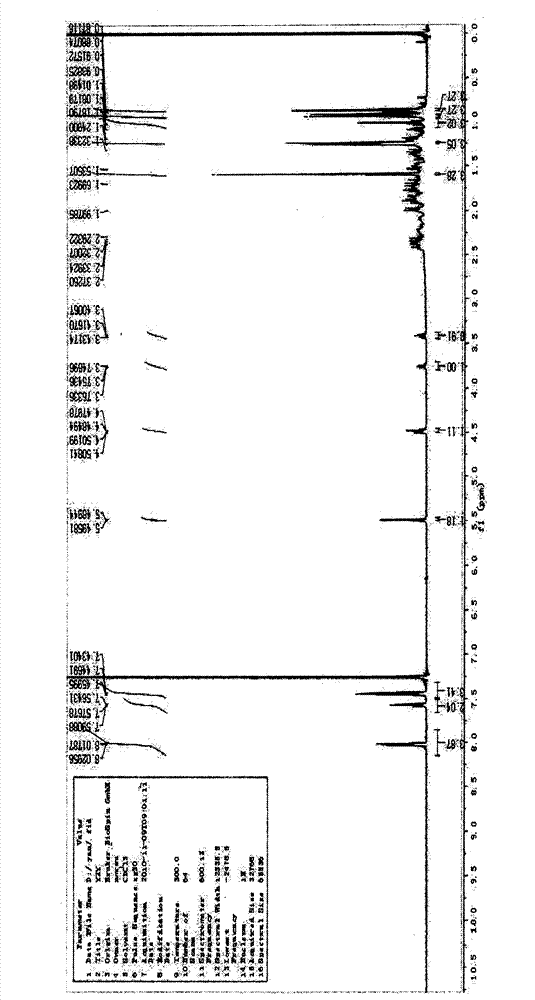

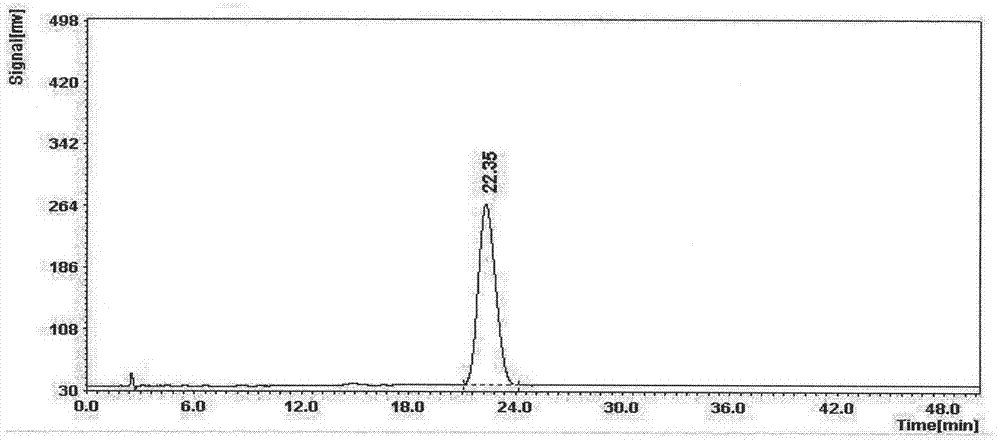

[0026] (1) Synthesis of Polygagenin Derivatives

[0027] Weigh 0.1g of polygalagenin, put it in a flask, add 15mL of dichloromethane, 5mL of pyridine, 4mL of benzoyl chloride, 0.005g of 4-dimethylaminopyridine, ice-water bath, stir for 0.5h, and obtain the crude product of polygalagenin derivative .

[0028] (2) Separation by silica gel column chromatography

[0029] Take the silica gel, weigh it accurately, place it in an evaporating dish, slowly pour the crude product solution of polygagenin derivatives into the evaporating dish, stir with a glass rod, dry it, and weigh it accurately. Another appropriate amount of silica gel (200-300 mesh) was taken, swelled with petroleum ether-acetone (volume ratio 100:10), and packed into a column.

[0030] Load the sample, and sequentially use petroleum ether-acetone (volume ratios of 100:10, 100:15, 100:20, 100:25, 100:30, 100:35) for 3 column volume gradient elution. The petroleum ether-acetone (volume ratio 100:35) elution fraction...

Embodiment 2

[0037] (1) Synthesis of Polygagenin Derivatives

[0038] Weigh 0.3 g of polygalagenin, put it in a flask, add 45 mL of dichloromethane, 10 mL of pyridine, 8 mL of benzoyl chloride, 0.005 g of 4-dimethylaminopyridine, stir in an ice-water bath, and stir for 1 hour with a magnetic stirrer to obtain polygala saponin derivatives Crude goods.

[0039] (2) Separation by silica gel column chromatography

[0040] Weigh an appropriate amount of silica gel, accurately weigh it, place it in an evaporating dish, slowly pour the crude product solution of polygagenin derivatives into the evaporating dish, stir with a glass rod, dry it, and accurately weigh it. Take an appropriate amount of silica gel (200-300 mesh), swell it with petroleum ether-acetone (volume ratio 100:10), and pack it into a column.

[0041] Load the sample, and sequentially use petroleum ether-acetone (volume ratios of 100:10, 100:15, 100:20, 100:25, 100:30, 100:35) for 3 column volume gradient elution. The petroleum...

Embodiment 3

[0048] (1) Synthesis of Polygagenin Derivatives

[0049] Weigh 0.5 g of polygalagenin, put it in a flask, add 75 mL of dichloromethane, 15 mL of pyridine, 12 mL of benzoyl chloride, 0.01 g of 4-dimethylaminopyridine, stir in an ice-water bath, and stir for 1 hour with a magnetic stirrer to obtain polygala saponin derivatives Crude goods.

[0050] (2) Separation by silica gel column chromatography

[0051] Weigh an appropriate amount of silica gel, accurately weigh it, place it in an evaporating dish, slowly pour the crude product solution of polygagenin derivatives into the evaporating dish, stir with a glass rod, dry it, and accurately weigh it. Take an appropriate amount of silica gel (200-300 mesh), swell it with petroleum ether-acetone (volume ratio 100:10), and pack it into a column.

[0052]Load the sample, and sequentially use petroleum ether-acetone (volume ratios of 100:10, 100:15, 100:20, 100:25, 100:30, 100:35) for 3 column volume gradient elution. The petroleum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com