Pulsed plasma thruster with water working medium

A pulsed plasma and thruster technology, which is applied in the direction of utilizing plasma, thrust reverser, machine/engine, etc., can solve the problems of low specific impulse of working medium and inability to generate a large amount of plasma, so as to improve the utilization rate and save costs. and space effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

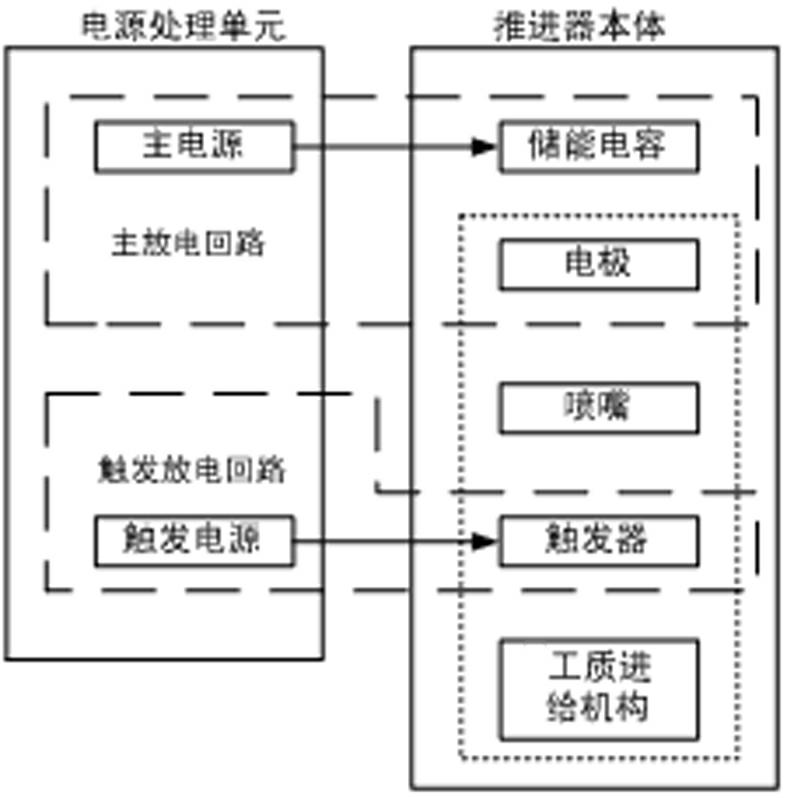

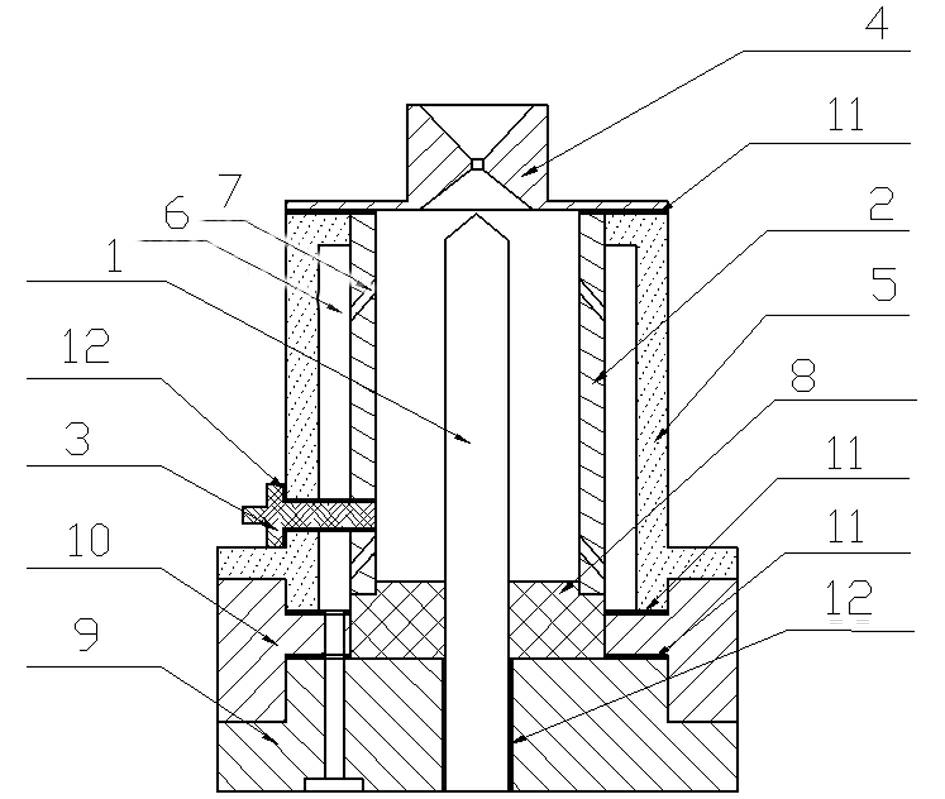

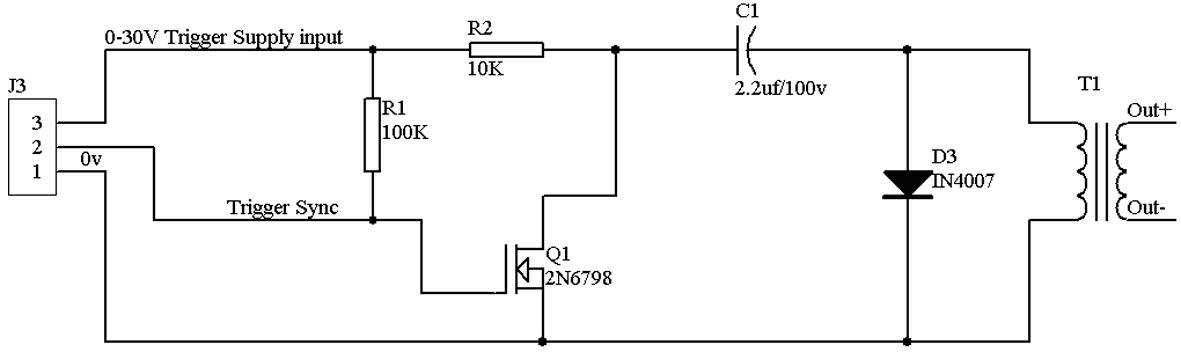

[0021] Such as figure 1 , 2 As shown, a hydraulic pulse plasma thruster according to the present invention includes two parts: a thruster body and a power processing unit. The propeller body is composed of a propeller structure and an energy storage capacitor. The propeller structure includes an anode 1, a cathode 2, a trigger 3, a working medium feeding mechanism and a nozzle 4. The anode 1 is a thoriated tungsten slender cylinder with a diameter of 2.4mm; the cathode 2 is a copper ring coaxial with the anode, with an inner diameter of 7mm, an outer diameter of 18mm, and a length of 26mm; an electrode cavity is formed between the anode 1 and the cathode 2, and the trigger 3 is connected to the cathode 2. The working fluid feeding mechanism includes an atomizer for atomizing the hydraulic fluid. The outside of the anode 1 and the cathode 2 are sealed with a casing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com