Method for producing nano fluid pathway with large area and available size base on SU-8 photosensitive resist

A technology of SU-8 and nanofluid, which is applied in the photolithographic process of the patterned surface, the process for producing decorative surface effects, optics, etc., can solve the problem of high processing cost, increased cost and cycle, electron beam or focused particles Long beam processing time and other issues, to achieve the effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

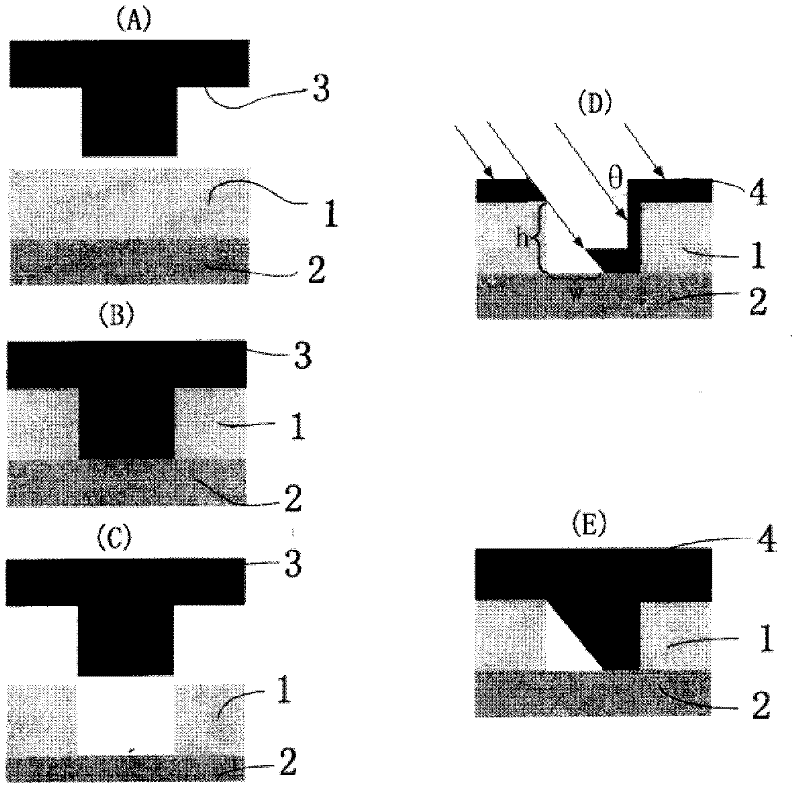

[0029] Embodiment 1 is carried out by the following process:

[0030] 1. Spin-coat SU-8 photoresist 1 on the surface of the quartz sheet, and form a quartz substrate 2 after baking, such as figure 1 as shown in (A);

[0031] 2. On the embossing template 3 with grating lines, the line height is h, spin-coat the release agent on the surface of the embossing template 3 and laminate it on the quartz substrate 2, as figure 1 As shown in (B), preheating softens the SU-8 photoresist 1 on the surface of the quartz substrate 2, and applies an embossing pressure of 1Mpa to the embossing template 3, so that the embossing template 3 is pressed into the softened SU-8 photoresist 1, keep the imprint pressure for 20 minutes and then cool naturally to obtain the combination of imprint template 3, quartz substrate 2 and SU-8 photoresist 1;

[0032] 3. Carry out ultraviolet exposure to the SU-8 photoresist 1 in the combination through the light-transmitting quartz substrate 2, the exposure ...

Embodiment 2

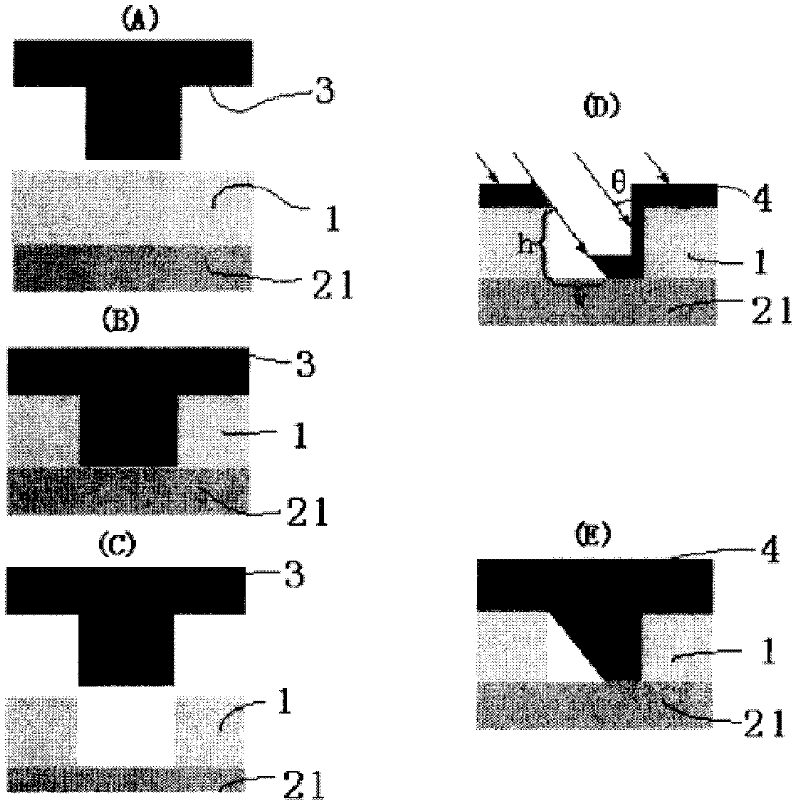

[0035] Spin-coat SU-8 photoresist 1 on the glass surface, and form a glass substrate 21 through baking, such as figure 2 as shown in (A);

[0036] Others are the same as the specific embodiment 1.

Embodiment 3

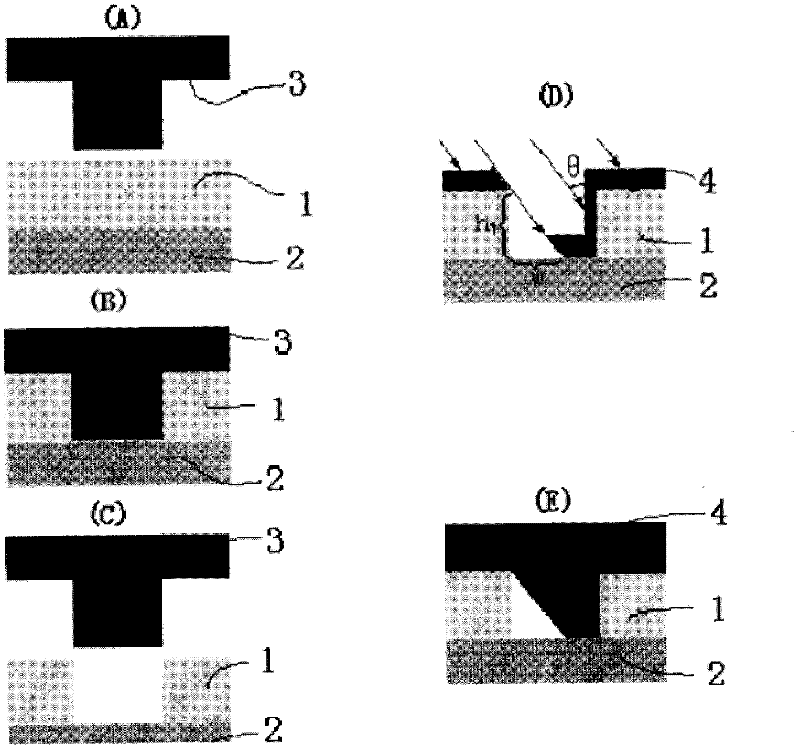

[0038] 1. Spin-coat SU-8 photoresist 1 on the surface of the quartz sheet, and form a quartz substrate 2 after baking, such as image 3 as shown in (A);

[0039] 2. On the embossing template 3 with grating lines, the line height is h 1 , laminated on the quartz substrate 2 after spin-coating a release agent on the surface of the imprint template 3, such as image 3 as shown in (B);

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com