Separation process for synthesizing mercaptoethanol by using hydrogen sulfide in crude gas

A mercaptoethanol, hydrogen sulfide technology, applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of corrosion of gas pipelines and equipment, low economic return, catalyst poisoning, etc. The effect of simple separation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

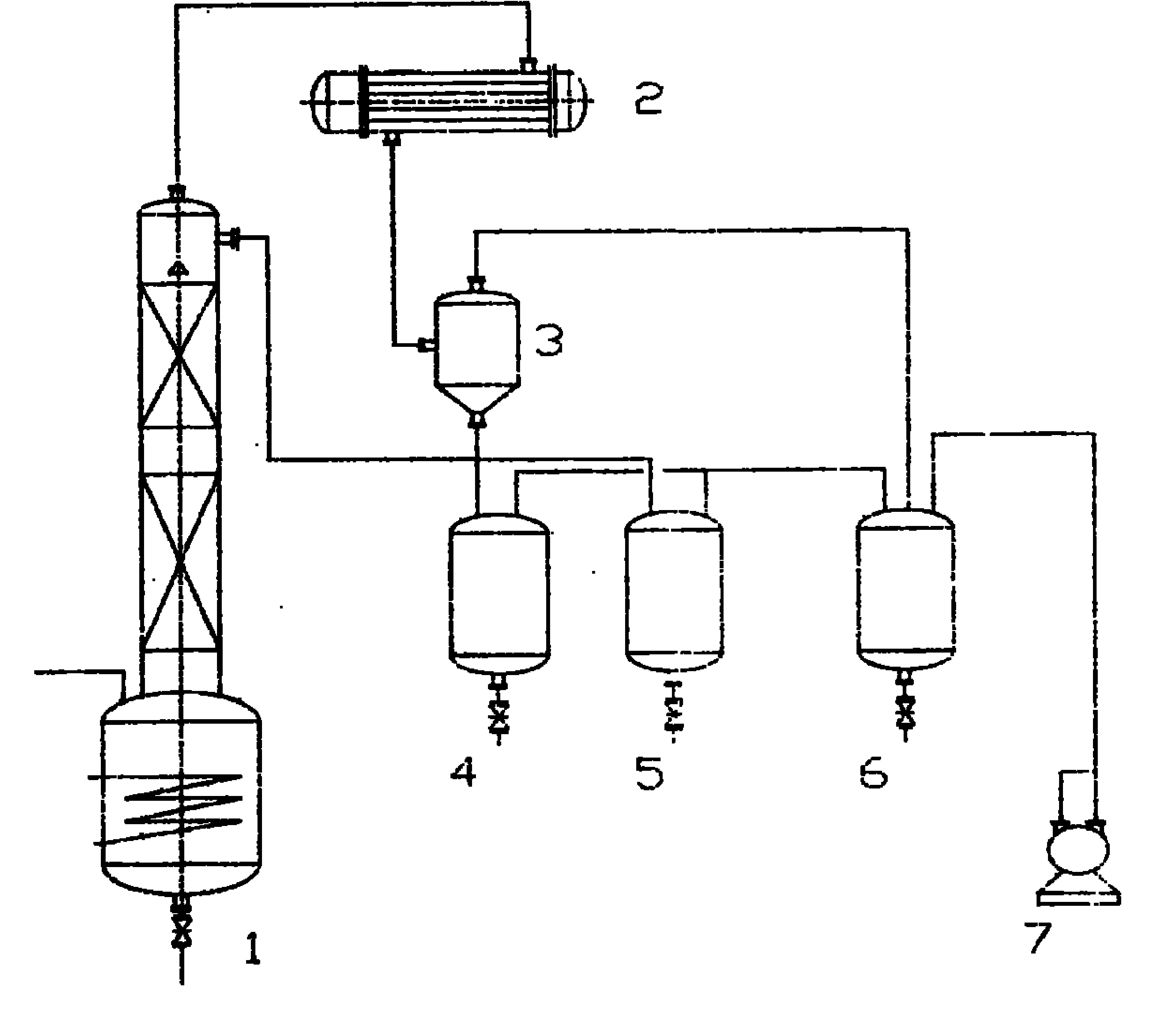

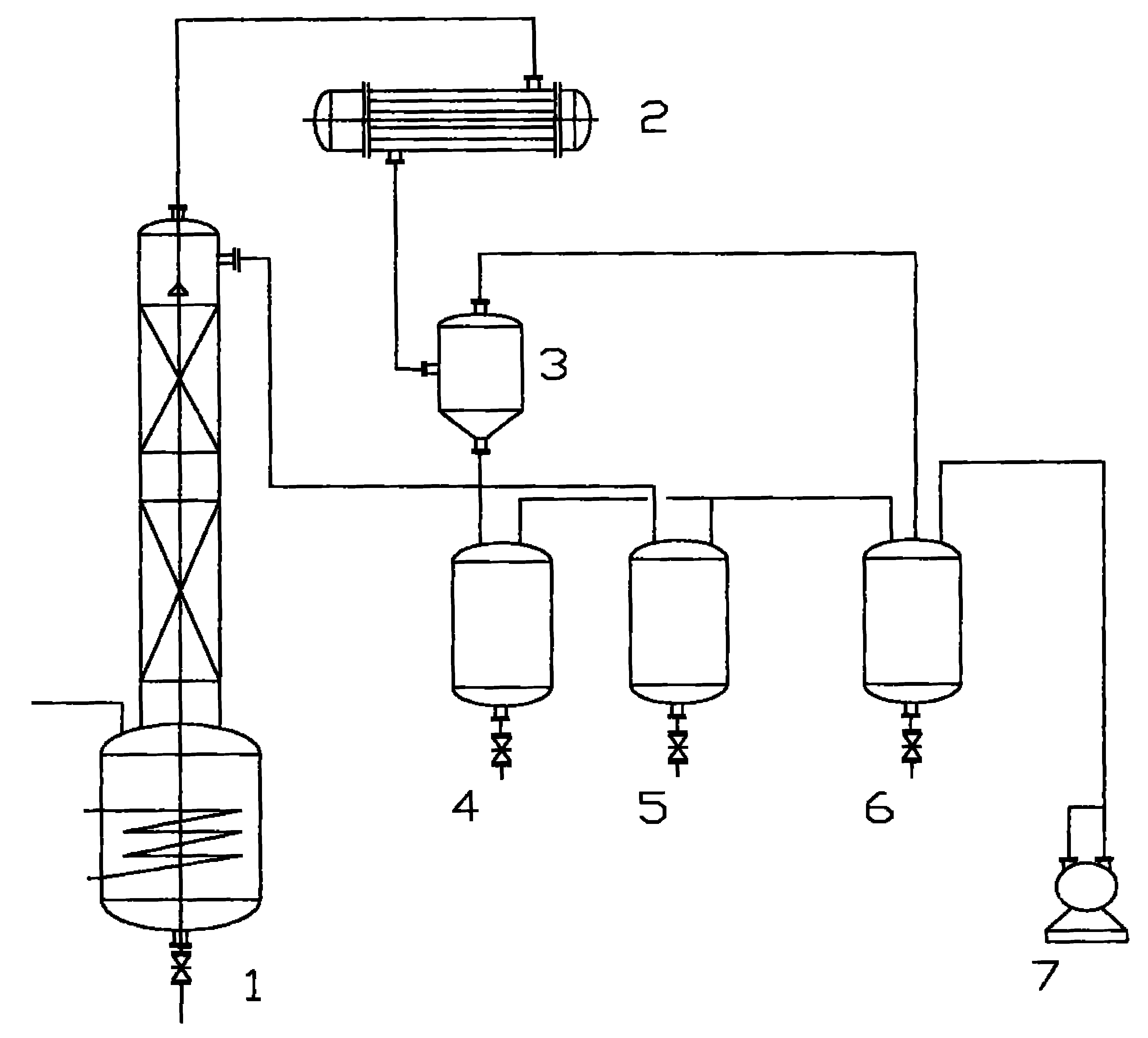

[0011] The separation process system for the synthesis of mercaptoethanol from hydrogen sulfide in crude gas is mainly composed of rectification tower, condensing cooler, gas-liquid separation tank, front fraction tank, product tank, buffer tank, vacuum unit and so on. The bottom of the rectification column is equipped with a feed inlet, the rising steam pipe on the top of the tower is connected to the inlet of the condensing cooler, the outlet of the condensing cooler is connected to the gas-liquid separator, the liquid outlet is connected to the front fraction tank and the finished product tank, and the gas-liquid separator The other interface of the front distillate tank and the finished product tank is connected with the buffer tank, and the buffer tank is connected with the vacuum unit. The lower ends of the front distillate tank, finished product tank and buffer tank are all provided with clean outlets. Add liquid crude mercaptoethanol with a content of about 90% into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com