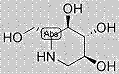

Method for preparing 1-deoxynojirimycin by membrane separation technology

A deoxynojirimycin and membrane separation technology, which is applied in the field of preparing 1-deoxynojirimycin by membrane separation technology, can solve serious pollution problems, achieve good product quality, reduce the generation of pollutants, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Fresh mulberry leaves are dried, crushed, weighed 10kg, put into an extraction tank, add 8 times the amount of deionized water and soak at 50°C for 5 hours, extract 3 times, filter the soaking solution and add a hollow polyamide fiber nanofiltration membrane system with a molecular weight cut-off of 300 to filter, Add an appropriate amount of deionized water for dialysis, add hollow polyamide fiber reverse osmosis membrane to concentrate the permeated liquid, add ethyl acetate to extract the concentrated solution for 3 times, concentrate the aqueous phase under reduced pressure, and dry in vacuum to obtain 21 products, of which 1-deoxynojiri Mycin content is 83.4%.

Embodiment 2

[0019] Fresh mulberry leaves are dried, crushed, weighed 50kg, put into an extraction tank, add 10 times the amount of deionized water and soak at 60°C for 3 hours, extract twice, filter the soaking liquid and add a hollow polyethersulfone nanofiltration membrane system with a molecular weight cut-off of 500, Add an appropriate amount of deionized water for dialysis, add hollow polyethersulfone reverse osmosis membrane to concentrate the permeated liquid, add ethyl acetate to extract the concentrated solution 4 times, concentrate the aqueous phase under reduced pressure, and dry in vacuum to obtain 112 products, of which 1-deoxynojiri Mycin content is 79.3%.

Embodiment 3

[0021] Fresh mulberry leaves are dried, crushed, weighed 100kg, put into the extraction tank, add 10 times the amount of deionized water and soak at 50°C for 4 hours, extract twice, filter the soaking liquid and add a hollow polytetrafluoroethylene nanofiltration membrane system with a molecular weight cut off of 400 to filter , add an appropriate amount of deionized water for dialysis, and then add a hollow composite reverse osmosis membrane to concentrate the permeated liquid. The concentrated solution is extracted 3 times with ethyl acetate, the aqueous phase is concentrated under reduced pressure, and vacuum-dried to obtain 232 products, of which 1-deoxynojiri The element content is 80.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com