Dual core-shell fluorescent material and preparation method thereof

A fluorescent material and core technology, applied in the field of core-shell structure fluorescent powder and its preparation, can solve the problems of poor thermal stability, difficulty in effective excitation in the visible light region, etc., and achieve improved electrical conductivity, excellent luminous performance, and high luminous intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

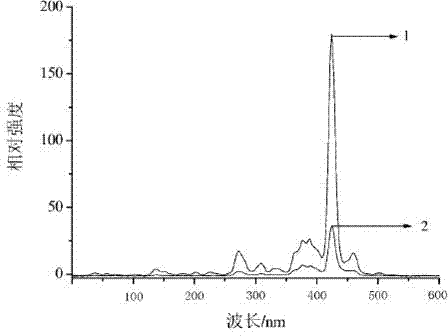

Image

Examples

Embodiment 1

[0027] 0.6Ba 2 Si 2 o 9 0.2SrF 2 :0.005HoSiO 2 Ag 0.00175

[0028] Dissolve 0.2g of PVP in 10mL of deionized water, stir for 15min, add 7mL to a concentration of 1×10 -3 mol / L Ag particle solution, stirred for 12h. Take the above-mentioned surface-treated Ag particle solution, and use the StOber method to coat the metal nanoparticles with SiO 2 , that is, 25 mL of absolute ethanol, 6 mL of ammonia water, 1 mL of tetraethyl orthosilicate (TEOS) and 5 mL of deionized water were added respectively, and the reaction was stirred for 6 h. Then add the Ba(NO 3 ) 2 Solution, SiO 2 , Sr(NO 3 ) 2 solution and holmium nitrate solution, stirred for 15 minutes, then added dropwise 15mL of 1M oxalic acid solution and HF in a stoichiometric ratio, and stirred for 15 minutes. Use ammonia water to adjust the pH value to 5, then stir for 10 min, filter the precipitate, wash the precipitate with deionized water, and dry.

[0029] The dried powder was ground, then sintered in air at...

Embodiment 2

[0032] 0.8Ba 2 Si 2 o 9 0.35SrF 2 :0.01HoSiO 2 Au 0.002

[0033] Dissolve 0.2g of PVP in 10mL of deionized water, stir for 15min, add 8mL to a concentration of 1×10 -3 mol / L Au particle solution, stirred for 12h. Take the above-mentioned surface-treated Au particle solution, and use the StOber method to coat metal nanoparticles with SiO 2 , that is, 25 mL of absolute ethanol, 6 mL of ammonia water, 1 mL of tetraethyl orthosilicate (TEOS) and 5 mL of deionized water were added respectively, and the reaction was stirred for 6 h. Then add the Ba(NO 3 ) 2 Solution, SiO 2 , Sr(NO 3 ) 2 solution and holmium nitrate solution, stirred for 15 minutes, then added dropwise 15mL of 1M oxalic acid solution and HF in a stoichiometric ratio, and stirred for 15 minutes. Use ammonia water to adjust the pH value to 5, then stir for 10 min, filter the precipitate, wash the precipitate with deionized water, and dry.

[0034] The dried powder was ground, then sintered in air at 140°C...

Embodiment 3

[0036] 0.7Ba 2 Si 2 o 9 0.45SrF 2 :0.07HoSiO 2 PD 0.0004

[0037] Dissolve 0.2g of PVP in 10mL of deionized water, stir for 15min, add 4mL to a concentration of 1×10 -3 mol / L Pd particle solution, stirred for 12h. Take the above-mentioned surface-treated Pd particle solution, and use the StOber method to coat metal nanoparticles with SiO 2 , that is, 25 mL of absolute ethanol, 6 mL of ammonia water, 1 mL of tetraethyl orthosilicate (TEOS) and 5 mL of deionized water were added respectively, and the reaction was stirred for 6 h. Then add the Ba(NO 3 ) 2 Solution, SiO 2 , Sr(NO 3 ) 2 solution and holmium nitrate solution, stirred for 15 minutes, then added dropwise 15mL of 1M oxalic acid solution and HF in a stoichiometric ratio, and stirred for 15 minutes. Use ammonia water to adjust the pH value to 5, then stir for 10 min, filter the precipitate, wash the precipitate with deionized water, and dry.

[0038] The dried powder was ground, then sintered in air at 130°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com