Copper indium gallium selenide (CIGS) solar cell and making method thereof

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as settlement, unfavorable solar cell photoelectric conversion efficiency, focal length or point maximum, etc., to increase light absorption volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to illustrate the structure of the CIGS solar cell of the present invention more clearly, a preferred embodiment is given and described in detail with accompanying drawings as follows.

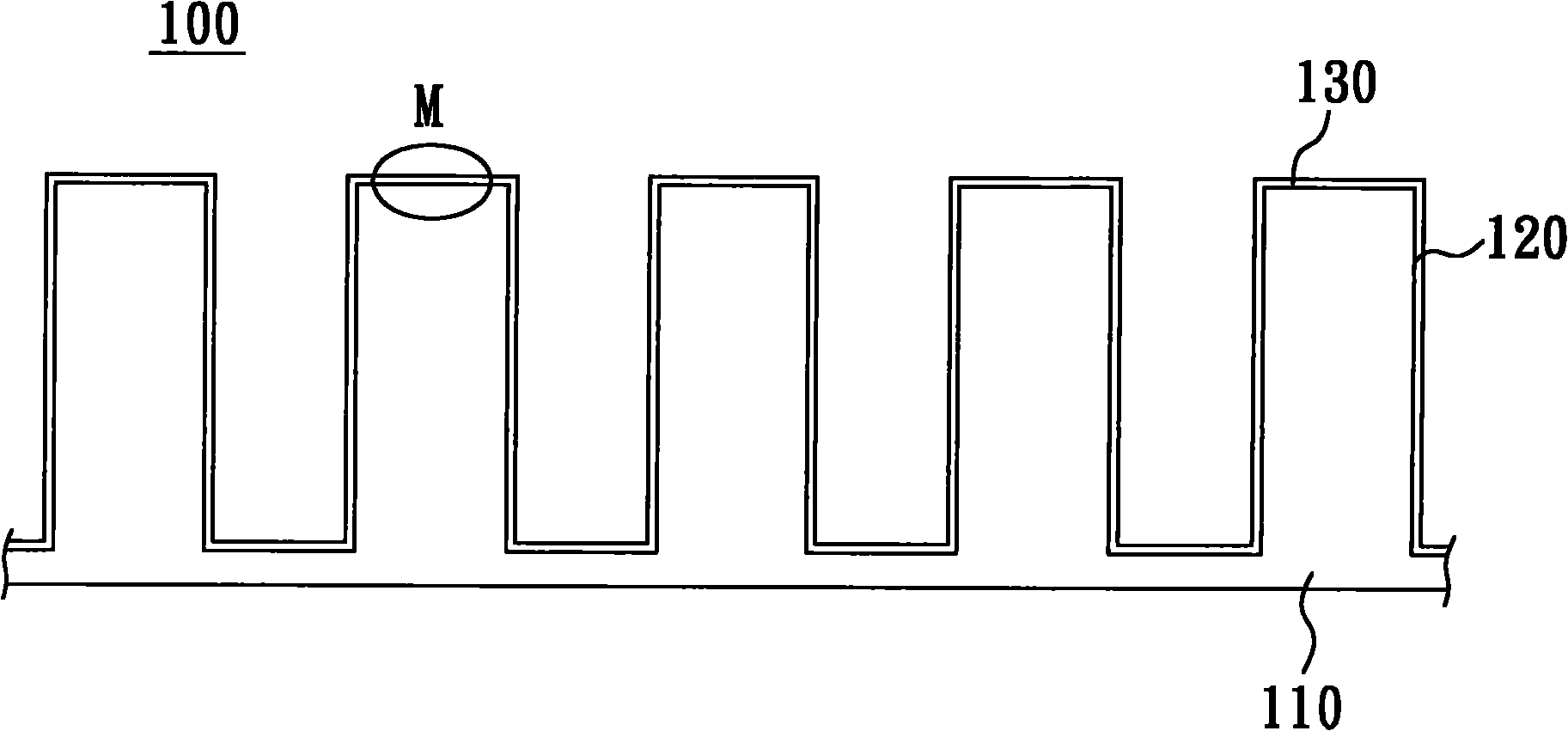

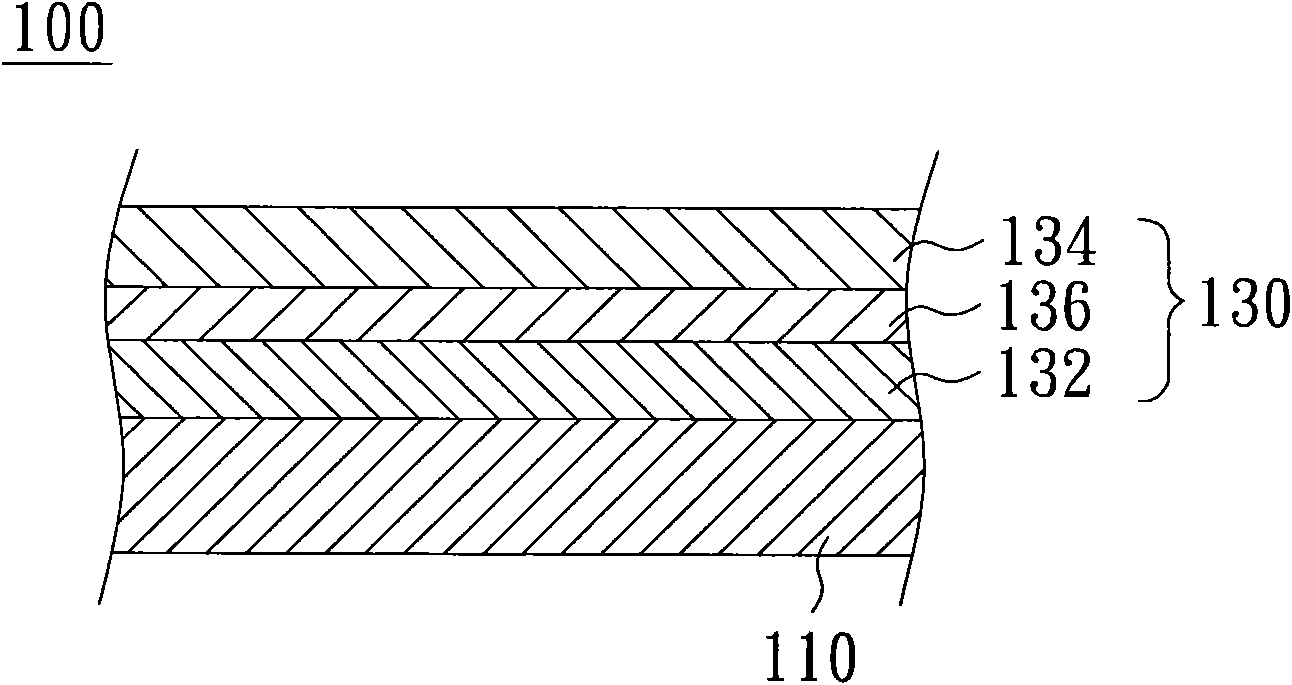

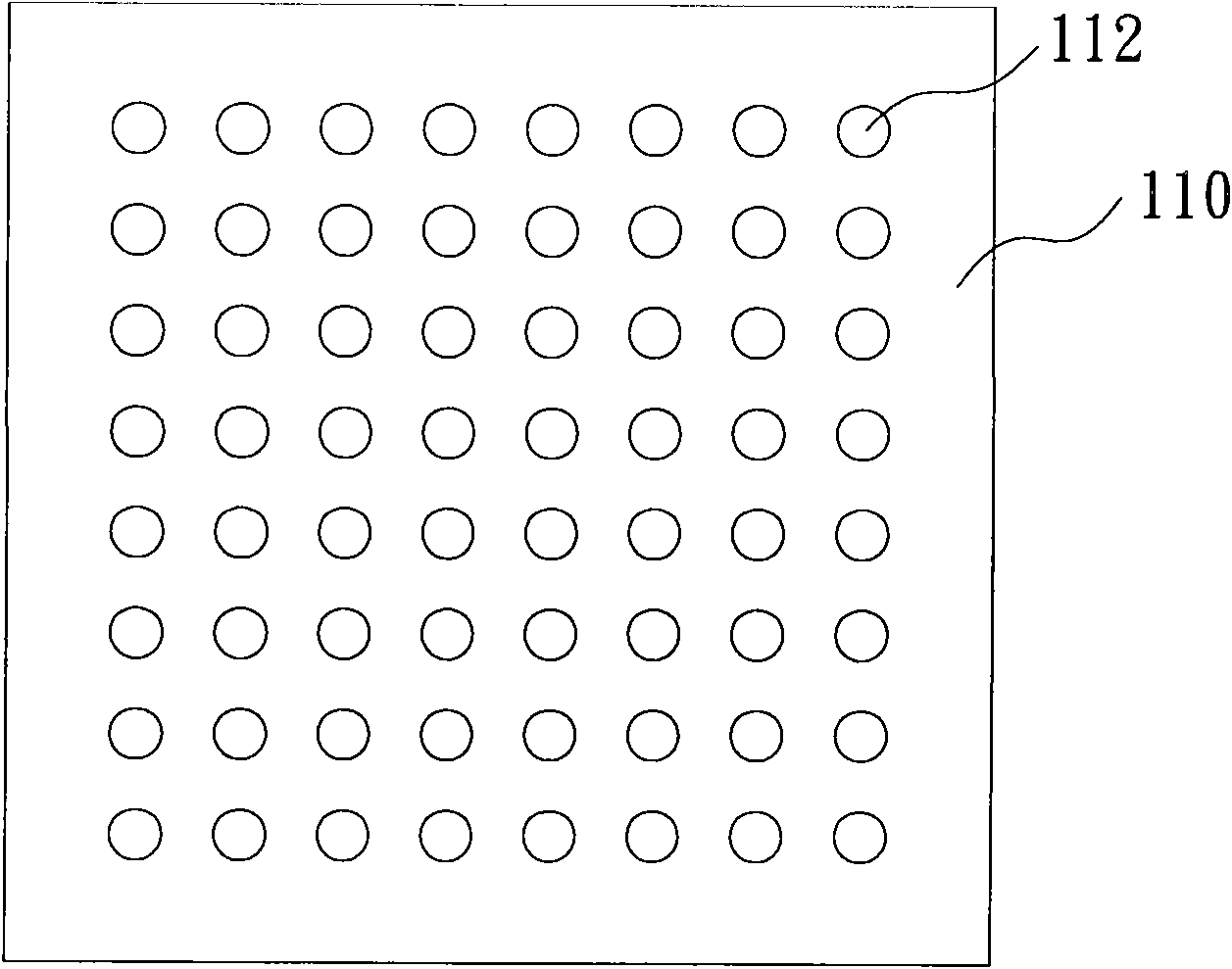

[0041] Please refer to Figure 1A , 1B , 2A and 2B are a preferred embodiment of the present invention, which respectively depict a schematic cross-sectional view of a CIGS solar cell of the present invention, a partial cross-sectional view, a top view of a glass substrate of the present invention, and Figure 2A Side view of the glass substrate. in:

[0042] The CIGS solar cell 100 includes a glass substrate 110 , a light absorbing surface 120 and a photoelectric conversion structure 130 . At least one surface of the glass substrate 110 includes a plurality of arrayed concave-convex portions 112, and the distance from the topmost to the bottommost end of each arrayed concave-convex portion 112 is a predetermined depth h. In this embodiment, the predetermined depth h is More...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com