Method for treating waste water containing acid and ammonia

A treatment method and wastewater technology, applied in the direction of heating water/sewage treatment, degassed water/sewage treatment, etc., can solve the problems of difficult control of process conditions, energy loss, high cost, etc., and achieve mature equipment, energy saving, and treatment costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

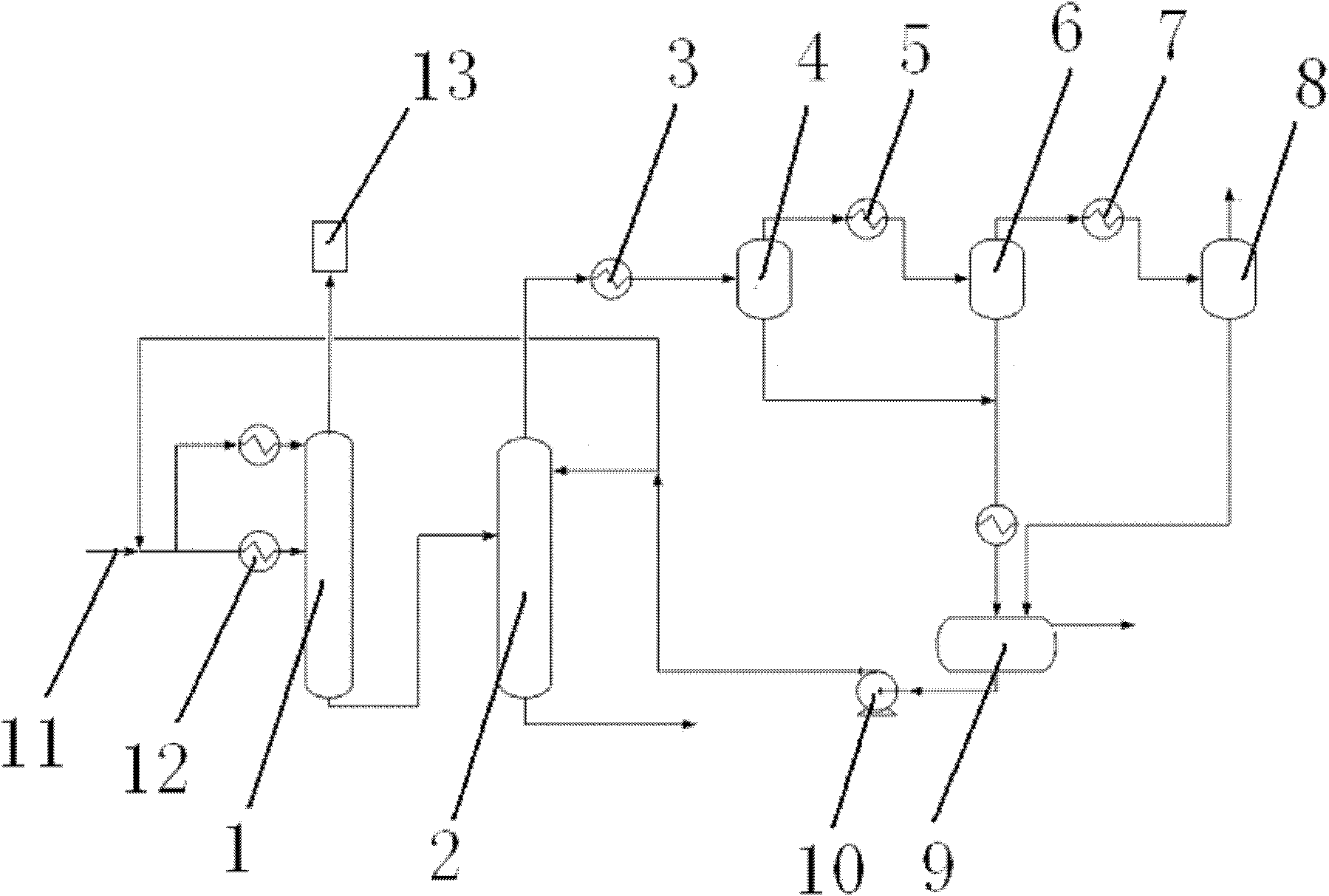

[0010] In this embodiment, the industrial wastewater containing acidic substances and ammonia gas discharged from industrial production is selected. First, the industrial wastewater to be treated is divided into two streams, cold and hot, and enters the tower from the upper part and the upper middle part of the deacidification tower respectively, and the control tower is adjusted. The top pressure is 0.1-0.4MPa, the tower top temperature is 40-80°C, the tower bottom pressure is 0.12-0.42Mpa, and the tower bottom temperature is 110-155°C, so that the acid gas is stripped continuously from the top of the tower, and then passes through the top of the tower After condensation and liquid separation, the acid gas enters the sulfur recovery unit, and the acid gas is incinerated by torch or directly put into the atmosphere; at the same time, the kettle liquid wastewater is extracted from the bottom of the deacidification tower through pipelines or pumps; The still liquid waste water en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com