Treatment method of anti-ultraviolet aromatic high-performance fiber

A technology of high-performance fiber and treatment method, applied in the direction of fiber treatment, light-resistant fiber, fiber type, etc., can solve the problems of initial fiber strength drop, inability to meet the requirements of use, clogging of spinneret holes, etc., to improve the strength retention rate, Long-lasting anti-ultraviolet function, the effect of broadening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

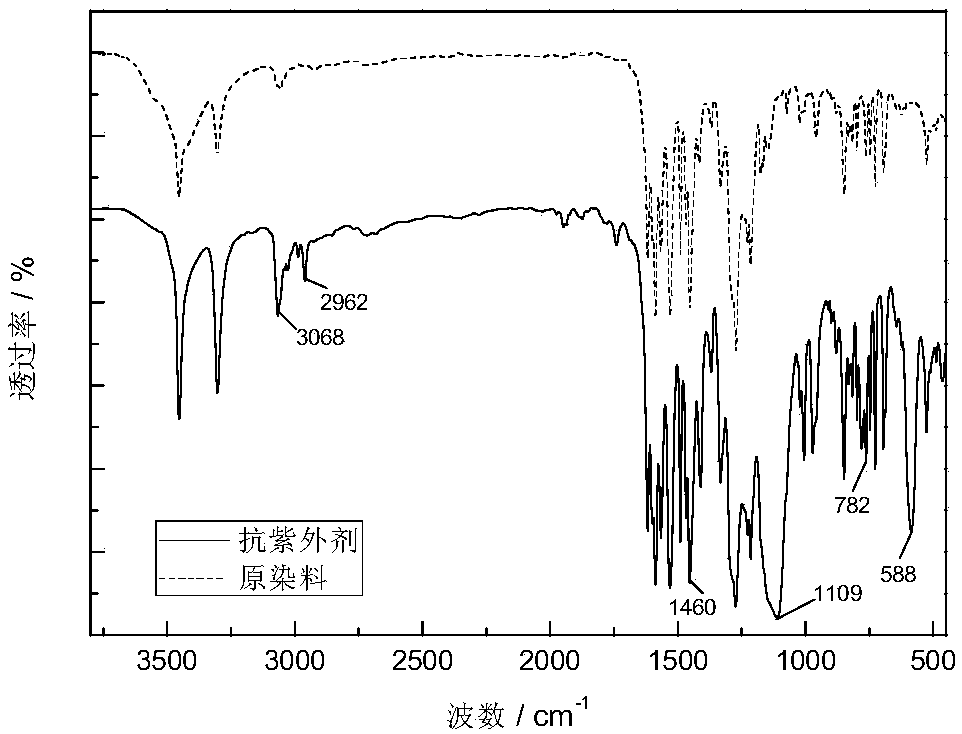

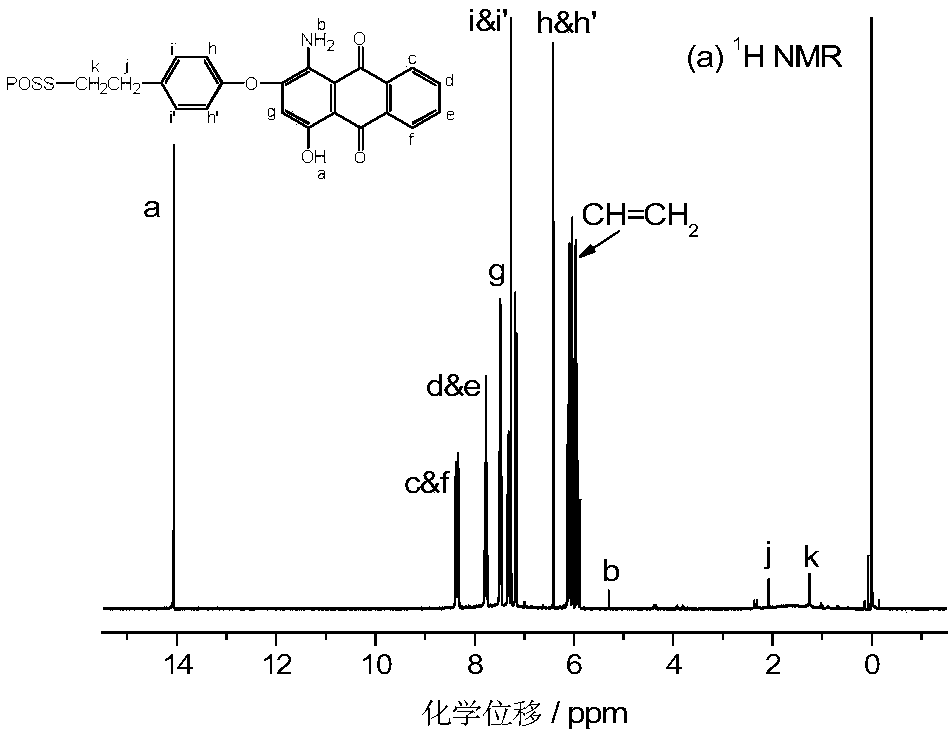

[0044] 0.3 parts of octavinyl silsesquioxane, 0.3 parts of octapropenyl silsesquioxane, and 0.8 parts of Disperse Red 60 dye which were ground into powders with a particle size of 0.5-1μm were mixed uniformly. Under nitrogen atmosphere, together with 0.15 Add parts of anhydrous aluminum chloride to 60 parts of carbon disulfide and 60 parts of carbon tetrachloride and stir until fully dissolved, then heat up to the boiling point of the mixed solvent, keep refluxing for 24 hours; after stopping heating, cool the mixed liquid to 0 with ice water ℃, then add 0.4 parts of triethylamine and 0.3 parts of diethylamine mixed solution and stir evenly, filter under reduced pressure to remove insoluble catalyst, the filtrate is distilled under reduced pressure to remove the solvent to obtain the crude product of anti-ultraviolet treatment agent; add the crude product to 250 parts In dichloromethane, reflux extraction in a Soxhlet extractor for 18 hours, followed by vacuum filtration to remo...

Embodiment 2

[0046] Mix 0.6 parts of octapropenyl silsesquioxane and 1.2 parts of Disperse Red 60 dye respectively ground into powders with a particle size of 0.5-1μm. Under nitrogen atmosphere, add 60 parts of benzene together with 0.15 parts of anhydrous ferric chloride. Stir in medium until it is fully dissolved, then heat to the boiling point of the mixed solvent, keep refluxing for 30 hours; after stopping heating, cool the mixed liquid to 2°C with ice water, then add 1.9 parts of diethylamine and stir evenly, filter under reduced pressure to remove Insoluble catalyst, the filtrate is distilled under reduced pressure to remove the solvent to obtain the crude product of anti-ultraviolet treatment agent; add the crude product to 65 parts of dichloromethane and 65 parts of toluene, reflux extraction in a Soxhlet extractor for 30 hours, and then perform vacuum filtration. The undissolved original dye is removed, and the filtrate is finally distilled under reduced pressure to obtain a refine...

Embodiment 3

[0048] Mix 0.6 parts of octabutenyl silsesquioxane and 3.2 parts of Disperse Yellow 42 dye which are respectively ground into powders with a particle size of 0.5-1μm. Under nitrogen atmosphere, together with 0.22 parts of anhydrous ferric chloride and 0.23 parts of anhydrous Magnesium chloride was added to 300 parts of carbon disulfide and 200 parts of benzene and stirred until fully dissolved, then heated to the boiling point of the mixed solvent, kept refluxed for 18 hours; after the heating was stopped, the mixture was cooled to 4°C with ice water, and then 1.5 parts of diethyl Stir the mixture of amine and 1.5 parts of dichloromethane evenly, filter under reduced pressure to remove the insoluble catalyst, and distill the filtrate under reduced pressure to remove the solvent to obtain the crude product of anti-ultraviolet treatment agent; add 450 parts of dichloromethane and 340 parts of trichloride to the crude product The methane is refluxed and extracted in a Soxhlet extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com