Method for purifying methylal

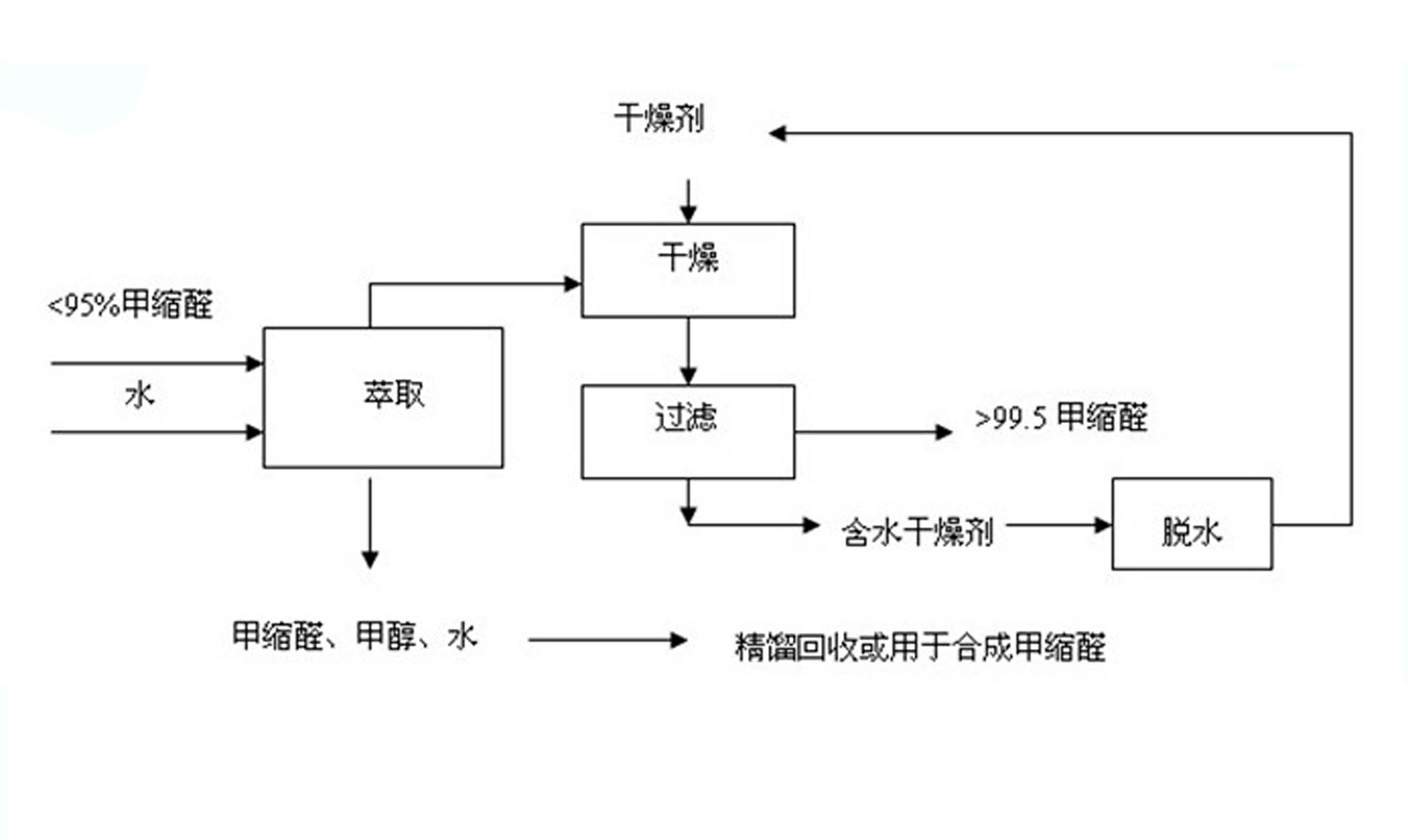

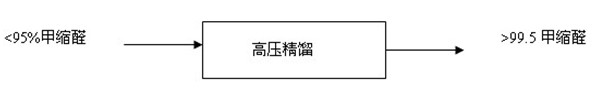

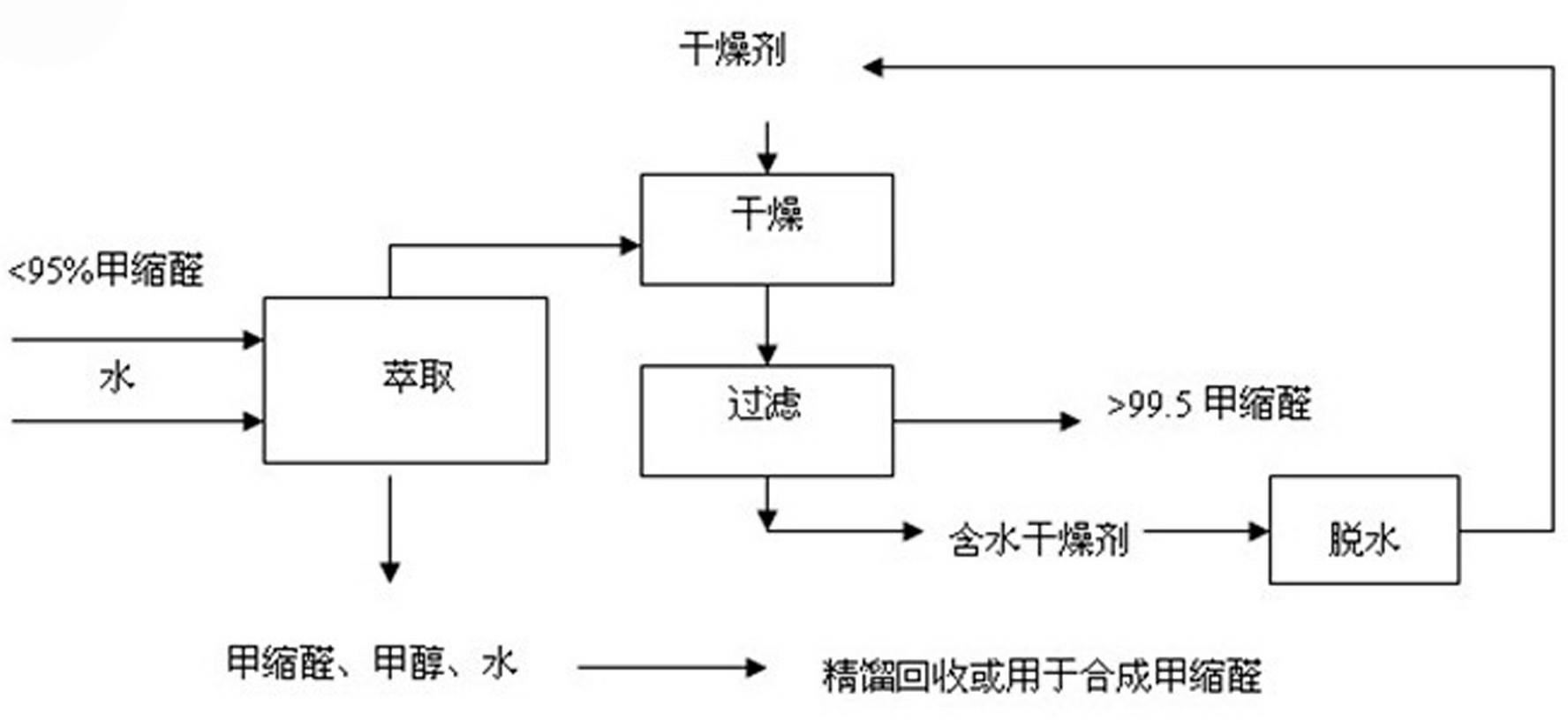

A purification method and methylal technology are applied in chemical instruments and methods, preparation of organic compounds, chemical industry and other directions, which can solve the problems of unsuitability for general application, unsuitable long-term use, complicated distillation process, etc. The effect of large-scale production, environmental protection and large amount of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 10kg of water to 100kg of methylal with a mass concentration of 91% and fully stir it. After standing still for 20 minutes, separate layers to obtain 63.5kg of the upper layer solution. Add 2.0kg of anhydrous magnesium sulfate (2.0kg of anhydrous The water absorption of magnesium sulfate is 2.0kg, and the water content of the upper layer of 63.5kg is about 1.9kg), and stirred for 5 minutes, after drying, the desiccant is filtered out to obtain 60.1kg of methylal with a mass concentration of 99.6%, and the obtained lower layer solution is methylal , a mixture of methanol and water, methylal and methanol can be recovered through rectification; hydrous magnesium sulfate can be recovered and reused after dehydration.

Embodiment 2

[0021] Add 30kg of water to 200kg of methylal with a mass concentration of 86% and stir well, stand still for 30 minutes, and separate layers to obtain 85.6kg of the upper layer solution. Add 10kg of anhydrous calcium chloride (10kg of anhydrous chloride Calcium water absorption is 9.7kg, 85.6kg upper layer solution has a water content of about 2.6kg), and stirred for 10 minutes, after drying, filter out the desiccant to obtain 81.1kg of methylal with a mass concentration of 99.7%, and the obtained lower layer solution is methylal The mixture of , methanol and water can be used for the synthesis of methylal; the calcium chloride in water can be reused after dehydration.

Embodiment 3

[0023] Add 150g of water to 500g of methylal with a mass concentration of 86% and stir well, let stand for 35 minutes, use a separatory funnel to separate layers, and obtain 393g of the upper layer solution, add 10g of molecular sieves to the upper layer solution, and stir for 5 minutes with a glass cup , Filter out the desiccant to obtain 381g of methylal with a mass concentration of 99.5%, and 257g of the resulting lower layer solution is a mixture of methylal, methanol and water; the water-containing molecular sieves are recycled after dehydration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com