Oxide up-conversion light-emitting material of perovskite structure and preparation method thereof

A technology of perovskite structure and luminescent materials, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve the effects of controllable size, easy synthesis, and high up-conversion luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

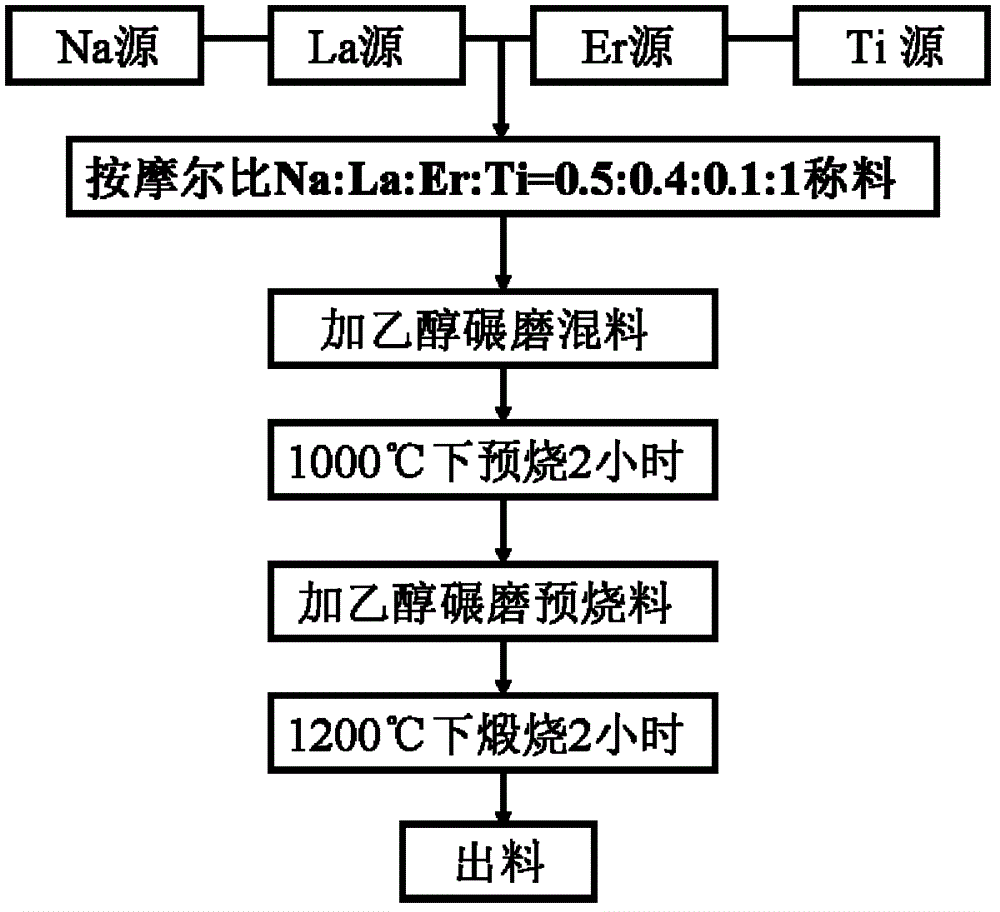

[0047] like figure 1 As shown, the up-conversion luminescent material Na was prepared by solid-state reaction method 0.5 La 0.4 Er 0.1 TiO 3 .

[0048] Raw material selection Na 2 CO 3 , La 2 o 3 、Er 2 o 3 and TiO 2 , press Na 0.5 La 0.4 Er 0.1 TiO 3 The stoichiometric ratio of Na, La, Er and Ti elements in the formula takes the selected raw materials, mixes them, adds absolute ethanol, grinds them in a mortar and mixes them well to get powder X 1 , wherein the mass ratio of absolute ethanol to the raw material mixture is 3:1. Powder X 1 Pre-fired in an alumina crucible, the pre-fired temperature is 1000°C, the heating rate is 3°C / min, keep warm for 2 hours and cool naturally to get the pre-fired powder X 2 . The pre-fired powder X 2 After grinding, it was calcined at 1200°C for 4 hours, the heating rate was 3°C / min, and after natural cooling, it was ground to obtain powder X 3 , the powder X 3 The up-conversion luminescent powder material Na obtained in t...

Embodiment 2

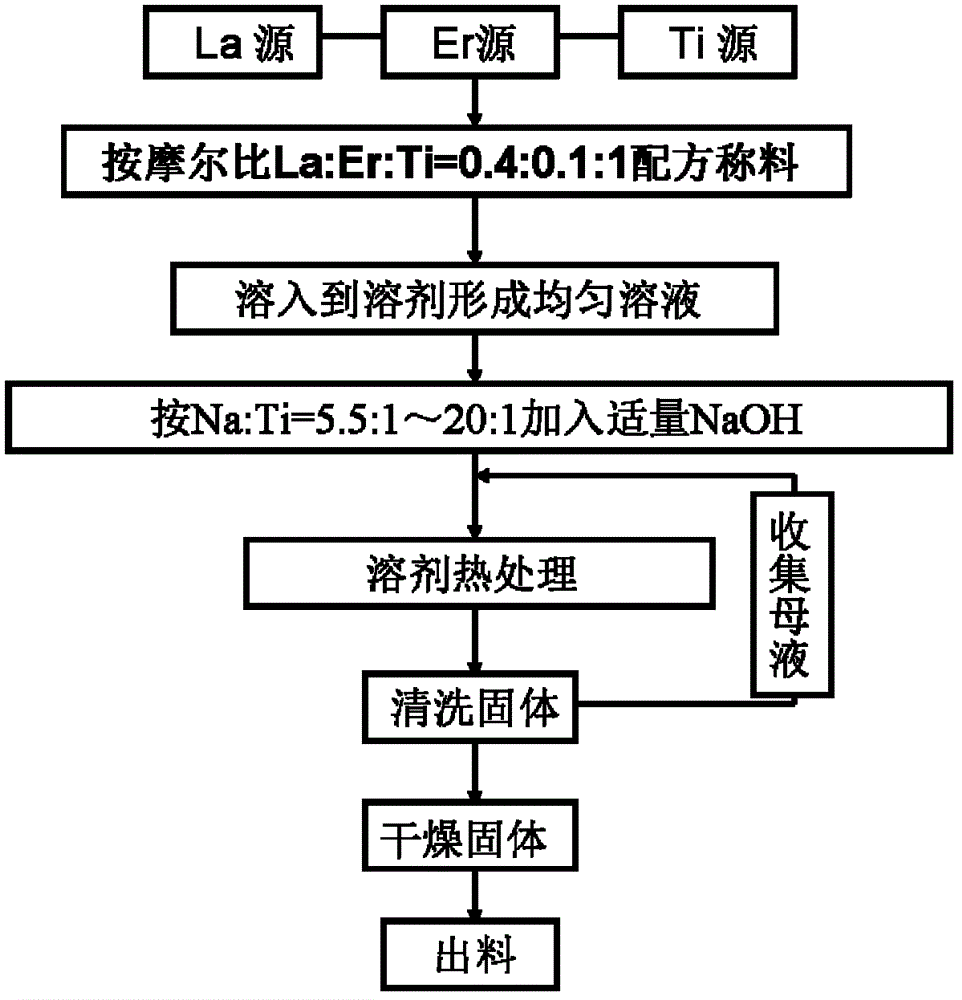

[0051] like figure 2 As shown, the solvothermal method was used to prepare Na 0.5 La 0.4 Er 0.1 TiO 3 Preparation of up-conversion luminescent materials.

[0052] The raw materials are NaOH, La(NO 3 ) 3 ·6H 2 O, Er(NO 3 ) 3 ·6H 2 O and C 16 h 36 o 4 Ti (tetrabutyl titanate), according to Na 0.5 La 0.4 Er 0.1 TiO 3 The stoichiometric ratios of La, Er and Ti elements are respectively selected as raw materials: La(NO 3 ) 3 ·6H 2 O: 1.73g, Er(NO 3 ) 3 ·6H 2 O: 0.46g, C 16 h 36 o 4 Ti: 3.40g, add the above raw materials into 40ml of deionized water, stir magnetically for 0.5h until they are uniformly dissolved, then add an appropriate amount of NaOH to it, add 4g of NaOH according to the molar ratio of Na:Ti=10:1, and then magnetically stir Or after ultrasonic vibration for 0.5h~1h, finally fill it into a stainless steel reactor with a polytetrafluoroethylene liner, the filling amount accounts for 3 / 5~4 / 5 of the volume of the polytetrafluoroethylene liner,...

Embodiment 3

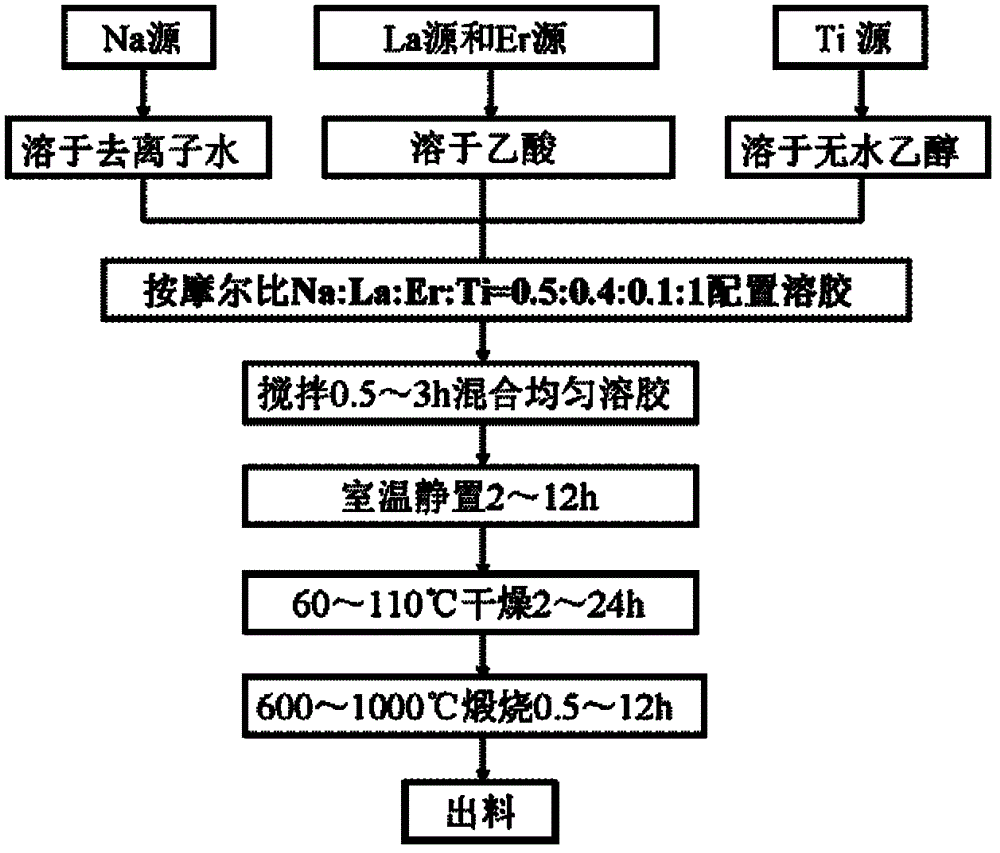

[0055] like image 3 As shown, using sol-gel to prepare Na 0.5 La 0.4 Er 0.1 TiO 3 Preparation of up-conversion luminescent materials.

[0056] Raw material selection NaNO 3 , La(NO 3 ) 3 ·6H 2 O, Er(NO 3 ) 3 ·6H 2 O and C 16 h 36 o 4 Ti (tetrabutyl titanate), according to Na 0.5 La 0.4 Er 0.1 TiO 3 The stoichiometric ratio of Na, La, Er and Ti elements will be 0.43g of NaNO 3 Dissolved in 10ml of deionized water, 1.73g of La(NO 3 ) 3 ·6H 2 O and 0.46g of Er(NO 3 ) 3 ·6H 2 O dissolved in 20ml of acetic acid, 3.40gC 16 h 36 o 4 Ti was mixed in 20ml of absolute ethanol, and stirred to obtain three homogeneous solutions, then, the three homogeneous solutions were mixed, and a transparent sol system was formed after magnetic stirring or ultrasonic oscillation for 3 hours, and the obtained transparent sol system was heated at room temperature for 20 The wet gel was obtained after standing at ~25°C for 12 hours, and the dry gel powder was obtained after dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com