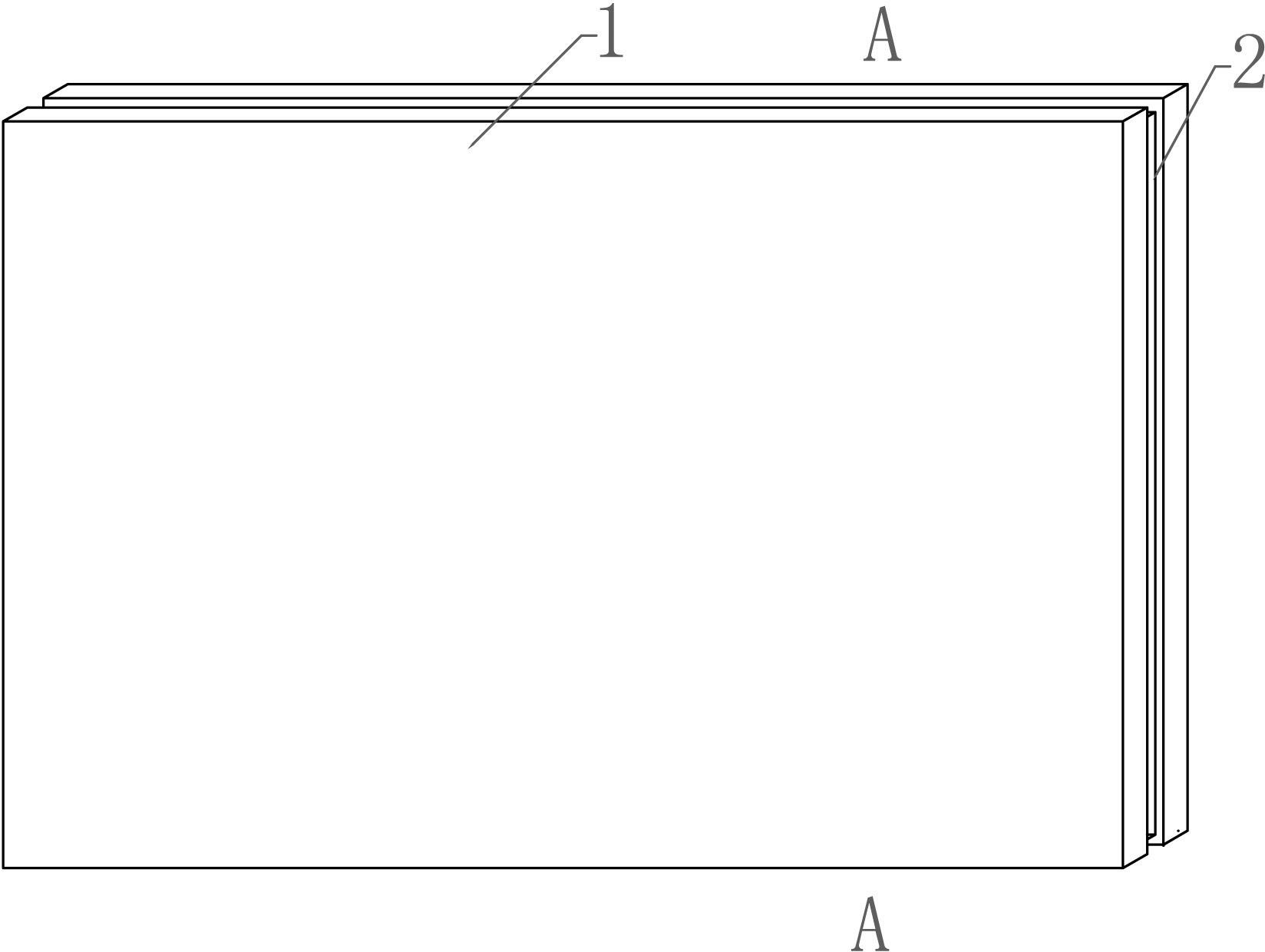

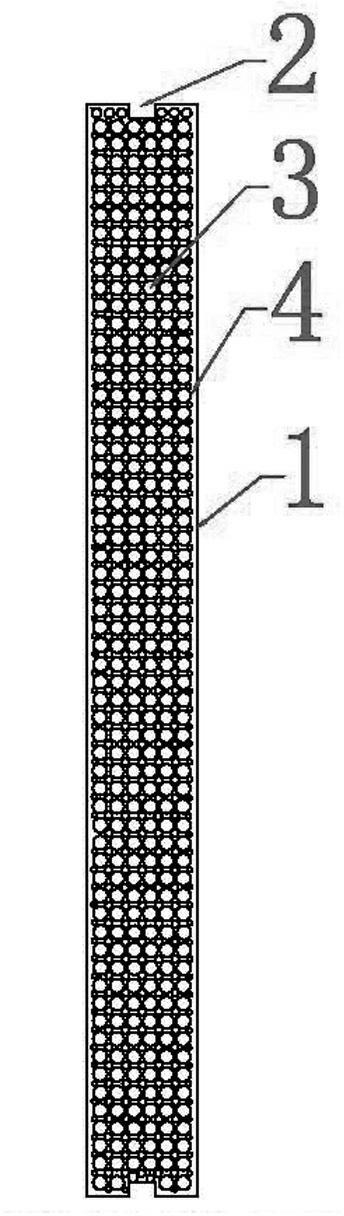

Flame repellent building heat insulation plate and manufacturing device and process thereof

A technology for building thermal insulation and thermal insulation boards, which is applied in thermal insulation, building components, manufacturing tools, etc., can solve the problems affecting the external wall thermal insulation and energy saving strategy of buildings, the combustion of external wall thermal insulation materials causing disasters, and the low strength of thermal insulation boards and unfavorable external wall decoration. and other problems, to achieve the effect of easy processing, simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] like Figure 4-9As shown, a device for producing the flame-resistant building insulation board of the present invention includes a device for producing gypsum shell bubbles for a flame-resistant building insulation board, and the device for producing gypsum shell bubbles for a flame-resistant building insulation board includes The water storage tank 16 with the air release valve 30, the air intake valve 33, the vacuum valve 18 of the water storage tank, the water inlet of the water storage tank and the water inlet valve 17, the water outlet and the water outlet valve 10 connected in sequence, and the water storage tank 16 with the refrigerant inlet 8. Refrigerant outlet 9, prilling tower vacuum pumping pipeline 12 and prilling tower 5 and ice prill coating drum 13 of ice pellet unloading valve 7, characterized in that:

[0037] The prilling tower 5 includes a tower body, a rotary water knife motor 6 arranged outside the top of the tower body, and the prilling tower 5 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com