Device for accelerating dynamic response of control system of diesel engine

A control system and dynamic response technology, applied in engine control, electrical control, fuel injection control, etc., can solve the problem of increasing the mechanical stress load of diesel engine parts, poor dynamic adjustment characteristics, and conflicting control indicators such as overshoot and stability. and other problems, to achieve the effect of speeding up dynamic adjustment and response speed, improving dynamic adjustment characteristics, and strengthening external performance capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

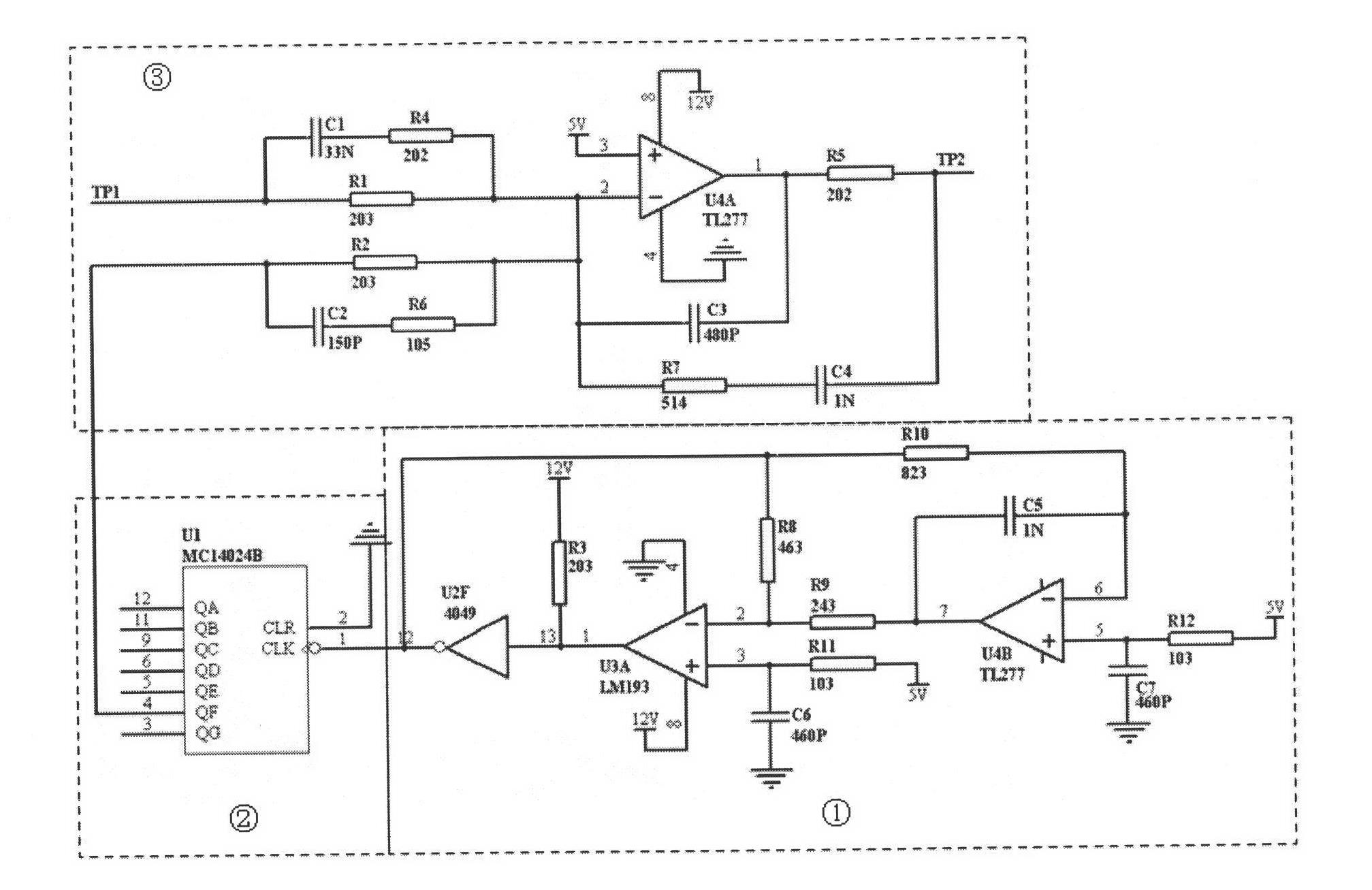

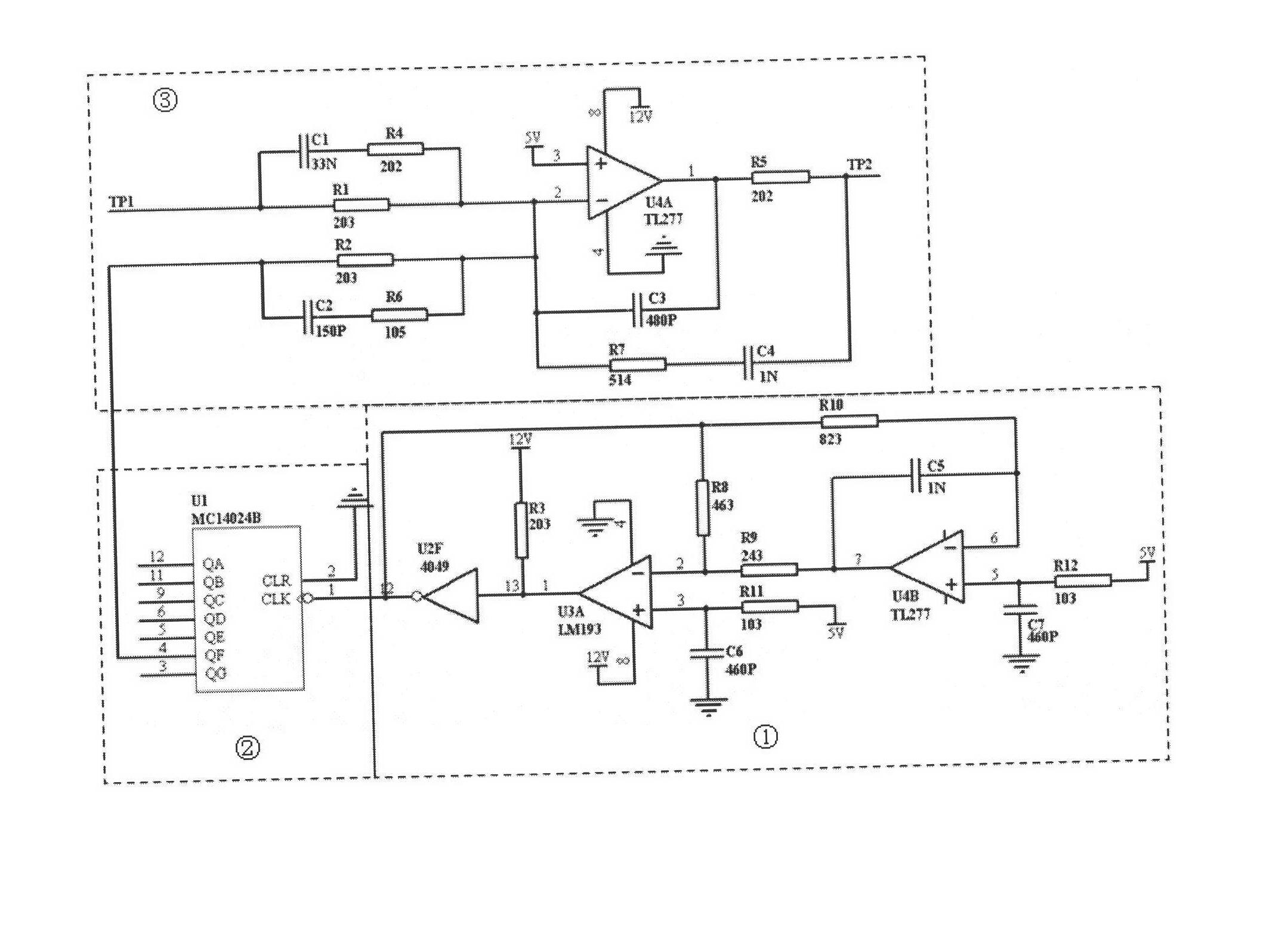

[0011] A device for accelerating the dynamic response of a diesel engine control system, which includes a comparator U3A, an operational amplifier (U4A, U4B), a logic inverter U2F, a binary counter (U1), a first resistor (R1), and a second resistor (R2) , the third resistor (R3), the fourth resistor (R4), the fifth resistor (R5), the sixth resistor (R6), the seventh resistor (R7), the eighth resistor (R8), the ninth resistor (R9), Tenth resistor (R10), eleventh resistor (R11), twelfth resistor (R12), first capacitor (C1), second capacitor (C2), third capacitor (C3), fourth capacitor (C4) , the fifth capacitor (C5), the sixth capacitor (C6), the seventh capacitor (C7) and the power supply, characterized in that the second pin of U3A is connected to the seventh pin of U4B through the ninth resistor (R9), U3A The second pin of U4B is connected to the sixth pin of U4B through the eighth resistor (R8) and the tenth resistor (R10) in series, and the 5V power supply is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com