Intelligent on-vehicle mobile type phase-change heat storage and supply system

A phase change heat storage and heat supply system technology, applied in heat storage equipment, vehicle components, indirect heat exchangers, etc., can solve problems such as difficult to find equipment maintenance, damage to heat exchange tubes, difficulties, etc., and achieve stable, safe and reliable operation , wide application market, simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

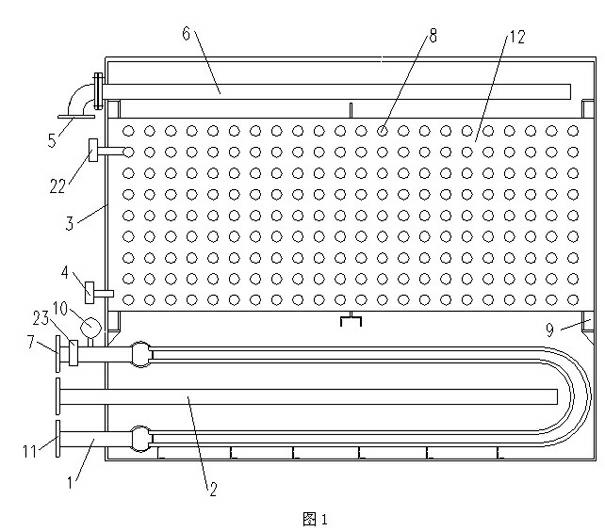

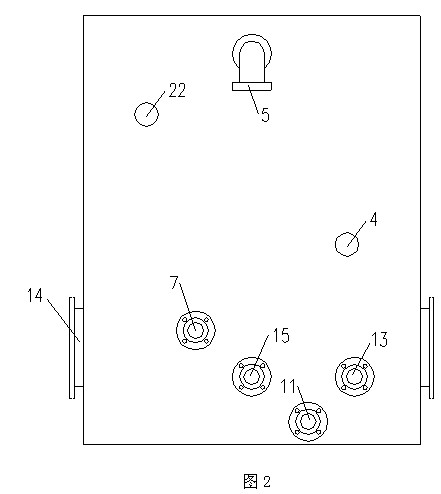

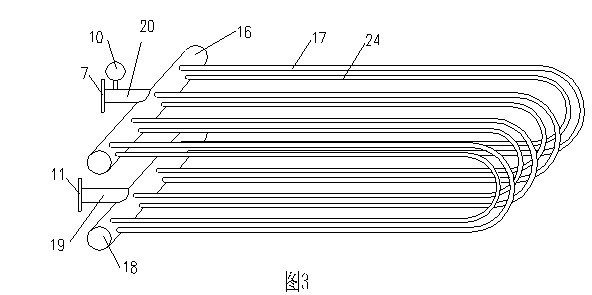

[0025]In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings.

[0026] The intelligent vehicle-mounted mobile phase-change heat storage heat supply system of the present invention includes a tractor and a phase-change heat storage heat exchange device, the phase change heat storage heat exchange device is fixedly installed on the tractor, and the phase change heat storage heat exchange device There is also an on-board monitoring unit.

[0027] The structure of the phase change heat storage heat exchange device is as follows: figure 1 and figure 2 As shown, the whole is a rectangular box structure, including a box body 3, and an insulation layer is set outside the box body 3 (not shown in the figure). Inside the box body 3, from bottom to top, there are heating tube group 1, cold water inlet pipe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com