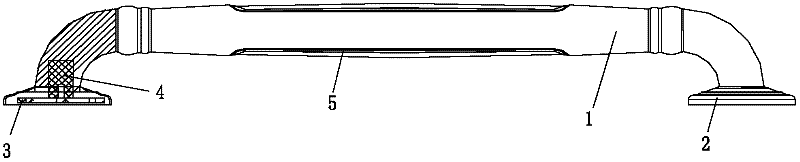

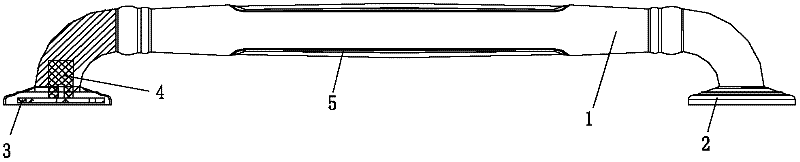

Anti-slip metal-like safety handrail and preparation method thereof

A technology of imitating metal and handrails, applied in sanitary equipment, household appliances, applications, etc., can solve the problems of reduced product versatility, easy to slip, single structure, etc., to increase safety, low cost and simple processing technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Mix 1300g of polyamide 6 material with 1000g of super-tough nylon material, 2000g of barium sulfate, and 20g of titanate coupling agent, add it to the extruder for granulation, and add 2500g of glass fiber during the granulation process to make a compound material particles. Install the safety armrest body mold on the injection molding machine, dry the granulated material and add it to the injection molding machine. Put the metal pin into the mold cavity first, and then inject the composite material into the mold cavity through the injection molding machine. After the product cools down, take out the blank of the composite material safety handrail body, and remove the gate and flash of the product. The processed blank is put into the vacuum electroplating furnace for vacuum electroplating conductive layer, and then chemical electroplating is carried out after taking it out. Make electroplated decorative layers with various metal textures, and electroplate parts. Put t...

Embodiment 2

[0035] Mix 1300g PBT (polybutylene terephthalate) material with 1000g PET (polyethylene terephthalate), 100g POE-g-MAH (maleic anhydride grafted ethylene-octene copolymer elastomer) , 2000g of ferrite and 20g of titanate coupling agent were mixed evenly, added to the extruder for granulation, and 2500g of glass fiber was added during the granulation process to make composite material granules. Install the safety armrest body mold on the injection molding machine, dry the granulated material and add it to the injection molding machine. Put the metal insert into the mold cavity first, and then inject the composite material into the mold cavity through the injection molding machine. After the product cools down, take out the blank of the composite material safety handrail body, and remove the gate and flash of the product. The processed blank is put into the vacuum electroplating furnace for vacuum electroplating conductive layer, and then chemical electroplating is carried out a...

Embodiment 3

[0038] Mix 1300g of polyamide 6 material with 1000g of polyamide 66 material, 2000g of barium sulfate, and 20g of titanate coupling agent, add them to the extruder for granulation, and add 2500g of glass fiber during the granulation process to make a compound material particles. Install the safety armrest body mold on the injection molding machine, dry the granulated material and add it to the injection molding machine. Put the metal insert into the mold cavity first, and then inject the composite material into the mold cavity through the injection molding machine. After the product cools down, take out the blank of the composite material safety handrail body, and remove the gate and flash of the product. The processed blank is put into the vacuum electroplating furnace for vacuum electroplating conductive layer, and then powder spraying is carried out after taking it out. Make decorative layers of various colors, handle the parts well, put the metal end caps into the armrest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com