Ultralow-concentration fracturing fluid and preparation method thereof

An ultra-low concentration, fracturing fluid technology, applied in chemical instruments and methods, drilling composition, etc., can solve problems such as affecting the effect of fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

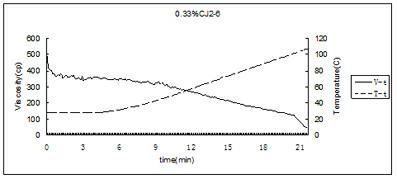

Image

Examples

preparation example Construction

[0048] The preparation method of the present invention is realized through the following steps:

[0049] (1) Preparation of solution A: Add water to the container, add water, and slowly add hydroxypropyl guar gum while stirring with a pump or a stirrer, and then add surfactant and clay stabilizer respectively , bactericide, temperature-resistant enhancer, continue to circulate or stir for 30 minutes, so that the liquid is fully mixed to form solution A;

[0050] (2) While pumping solution A, mix solution A and cross-linking agent according to the volume ratio of solution A:cross-linking agent=100:1~100:2 to form fracturing fluid.

Embodiment 1

[0051] Embodiment 1: Prepare each material by following consumption:

[0052] 93.35 parts of water

[0053] Hydroxypropyl guar gum 0.25 parts

[0054] Inorganic boron crosslinking agent 1.0 parts

[0055] Hydrocarbon emulsifier 0.4 parts

[0056] Trimethylhydroxypropyl quaternary ammonium salt clay stabilizer 0.2 parts

[0057] Dodecyl dimethyl benzyl ammonium chloride 0.05 part

[0058] Monoethanolamine 0.2 part

[0059] The material of above-mentioned batching is prepared by following steps:

[0060] (1) Preparation of solution A: Add water to the container, add water, and slowly add hydroxypropyl guar gum while stirring with a pump or a stirrer, and then add hydrocarbon emulsifier, trimethyl Hydroxypropyl quaternary ammonium salt clay stabilizer, dodecyl dimethyl benzyl ammonium chloride, monoethanolamine, continue to circulate or stir for 30 minutes, so that the liquid is fully mixed to form solution A;

[0061] (2) While pumping solution A, mix solution A and inorg...

Embodiment 2

[0062] Embodiment 2: each material is prepared according to the following consumption:

[0063] Water 95.375 parts

[0064] Hydroxypropyl guar gum 0.3 parts

[0065] Inorganic boron crosslinking agent 1.5 parts

[0066] 1.2 parts of alkyl sulfonate emulsifier

[0067] Trimethylhydroxypropyl quaternary ammonium salt clay stabilizer 0.6 parts

[0068] Isothiazolinone 0.275 parts

[0069]Triethanolamine 0.5 part

[0070] The material of above-mentioned batching is prepared by following steps:

[0071] (1) Preparation of solution A: Add water to the container, add water, and slowly add hydroxypropyl guar gum while stirring with a pump or stirrer, and then add alkyl sulfonate emulsification Agent, trimethylhydroxypropyl quaternary ammonium salt clay stabilizer, isothiazolinone, triethanolamine, continue to circulate or stir for 30 minutes, so that the liquid is fully mixed to form solution A;

[0072] (2) While pumping solution A, mix solution A and inorganic boron crosslink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com