Flora construction method for residual oil gasification exploitation of oil deposit

A construction method and reservoir technology, applied in the direction of using microorganisms, chemical instruments and methods, bacteria, etc., to achieve the effect of overcoming bias and one-sidedness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

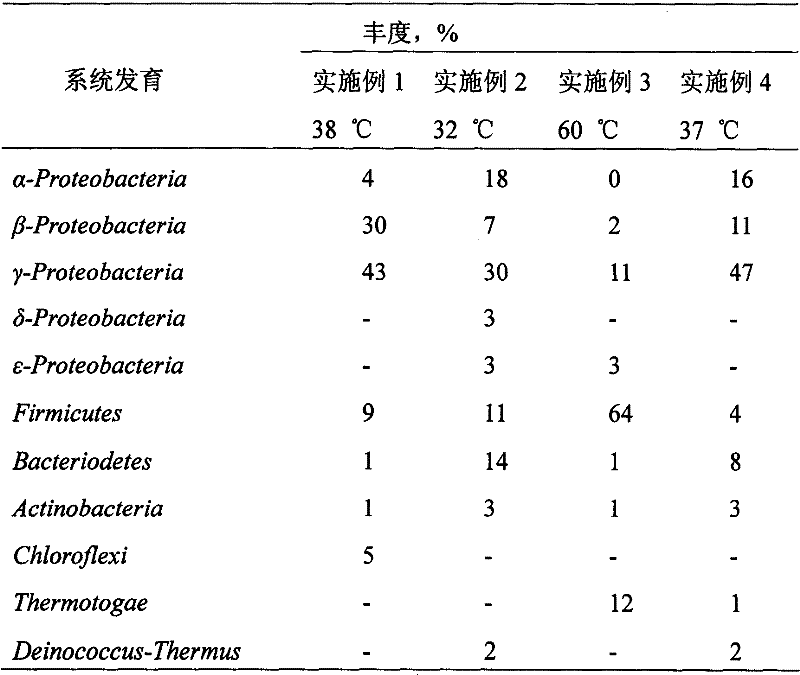

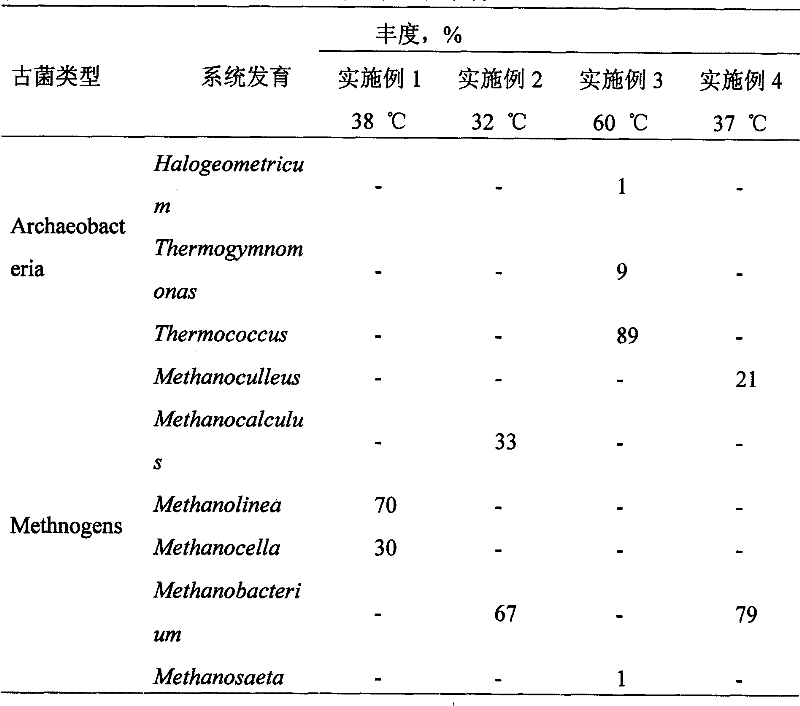

Embodiment 1

[0017] The sample comes from the fluid produced by an oil well in Huabei Oilfield, and the reservoir temperature is 38°C. 30 μL of mixed alkanes (n-pentadecane, n-hexadecane, n-heptadecane, n-octadecane, n-nonadecane and n-eicosane are uniformly mixed in equal volumes), vitamin solution 0.2mL (vitamin B121.0mg / L, biotin 20.0mg / L, folic acid 20.0mg / L, niacin 50.0mg / L, D-Ca-pantothenate 50.0mg / L, p-aminobenzoic acid 50.0mg / L, vitamin B6-hydrochloric acid 100.0mg / L, riboflavin 50.0mg / L, vitamin B1-hydrochloric acid (2H 2 (2) 50.0mg / L, lipoic acid 50.0mg / L) and trace element solution 0.1mL (CoCl 2 ·6H 2 O 0.50g / L, CuCl 2 2H 2 O 0.10g / L, FeCl 2 4H 2 O 7.50g / L, H 3 BO 3 1.00g / L, MnCl 2 4H 2 O 0.50g / L, Na 2 MoO 4 2H 2 O 0.10g / L, NiCl 2 ·6H 2 O 0.10g / L, ZnCl 2 ·6H 2 O 0.50g / L) and inorganic salt solution 45mL (NaCl0.50g / L, MgCl 2 ·6H 2 O 0.10g / L, CaCl 2 2H 2 O 0.10g / L, NH 4 Cl 0.25g / L, KH 2 PO 4 0.20g / L, KCl0.30g / L, NaHCO 3 2.50g / L, Na 2 S·9H 2 O 0.5g / L)...

Embodiment 2

[0019] The sample comes from the fluid produced from an oil well in Xinjiang Oilfield, and the reservoir temperature is 32°C. 70 μL of mixed alkanes (n-pentadecane, n-hexadecane, n-heptadecane, n-octadecane, n-nonadecane and n-eicosane are uniformly mixed in equal volumes), vitamin solution 0.2mL (vitamin B121.0mg / L, biotin 20.0mg / L, folic acid 20.0mg / L, niacin 50.0mg / L, D-Ca-pantothenate 50.0mg / L, p-aminobenzoic acid 50.0mg / L, vitamin B6-hydrochloric acid 100.0mg / L, riboflavin 50.0mg / L, vitamin B1-hydrochloric acid (2H 2 (2) 50.0mg / L, lipoic acid 50.0mg / L) and trace element solution 0.1mL (CoCl 2 ·6H 2 O 0.50g / L, CuCl 2 2H 2 O 0.10g / L, FeCl 2 4H 2 O 7.50g / L, H 3 BO 31.00g / L, MnCl 2 4H 2 O 0.50g / L, Na 2 MoO 4 2H 2 O 0.10g / L, NiCl 2 ·6H 2 O 0.10g / L, ZnCl 2 ·6H 2 O 0.50g / L) and inorganic salt solution 45mL (NaCl0.50g / L, MgCl 2 ·6H 2 O 0.10g / L, CaCl 2 2H 2 O 0.10g / L, NH 4 Cl 0.25g / L, KH 2 PO 4 0.20g / L, KCl0.30g / L, NaHCO 3 2.50g / L, Na 2 S·9H 2 O 0.5g / ...

Embodiment 3

[0021] The sample comes from a well produced fluid in Shengli Oilfield, and the reservoir temperature is 60°C. 100 μL of mixed alkanes (n-pentadecane, n-hexadecane, n-heptadecane, n-octadecane, n-nonadecane and n-eicosane are uniformly mixed in equal volumes), 0.2 mL of vitamin solution (vitamin B12 1.0 mg / L, biotin 20.0mg / L, folic acid 20.0mg / L, niacin 50.0mg / L, D-Ca-pantothenate 50.0mg / L, p-aminobenzoic acid 50.0mg / L, vitamin B6-hydrochloric acid 100.0mg / L, riboflavin 50.0mg / L, vitamin B1-hydrochloric acid (2H 2 (2) 50.0mg / L, lipoic acid 50.0mg / L) and trace element solution 0.1mL (CoCl 2 ·6H 2 O 0.50g / L, CuCl 2 2H 2 O 0.10g / L, FeCl 2 4H 2 O 7.50g / L, H 3 BO 3 1.00g / L, MnCl 2 4H 2 O 0.50g / L, Na 2 MoO 4 2H 2 O 0.10g / L, NiCl 2 ·6H 2 O 0.10g / L, ZnCl 2 ·6H 2 O 0.50g / L) and inorganic salt solution 45mL (NaCl0.50g / L, MgCl 2 ·6H 2 O 0.10g / L, CaCl 2 2H 2 O 0.10g / L, NH 4 Cl 0.25g / L, KH 2 PO 4 0.20g / L, KCl0.30g / L, NaHCO 3 2.50g / L, Na 2 S·9H 2 O 0.5g / L) to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com