Method for recovering gold from gold-containing barren solution and purifying gold-containing barren solution

A technology for recovering gold and barren liquid, applied in the direction of improving process efficiency, etc., can solve the problems of high processing cost, affecting gold cyanide leaching, increasing calcium ions, etc., and achieve the effect of reducing pollution coefficient and recycling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

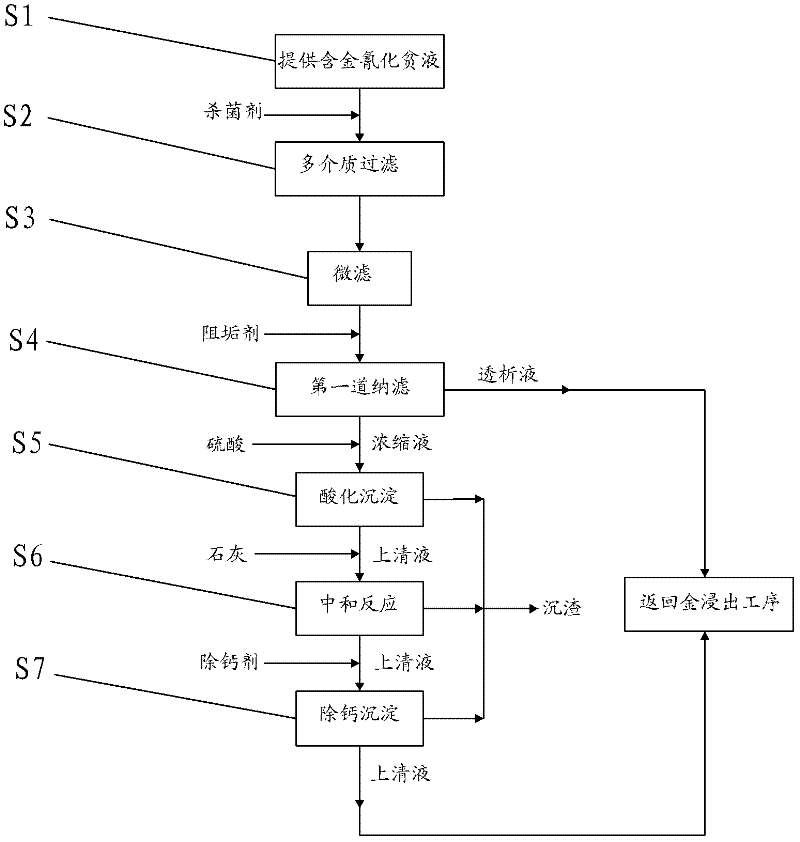

[0027] Such as figure 1 Shown, a kind of purification method of the present invention reclaims gold and barren solution thereof from gold-containing barren solution, realizes by following steps successively:

[0028] Step S1: providing a gold-containing cyanide poor solution as a feed solution.

[0029] Step S2: sieving and filtering through a multimedia filter after adding a bactericide to the gold-cyanide-containing barren solution.

[0030] Wherein, the bactericide is one or a mixture of isothiazolinone and bromo-containing aziramide, and the dosage is 0.5 ppm. Bactericides are non-oxidizing substances that inactivate and inhibit microbial contamination, including bacteria, fungi, and algae. Adding a bactericide before entering the microfiltration membrane and nanofiltration membrane system in the microfiltration step S3 and the first nanofiltration step S4 can inhibit microbial contamination of the microfiltration membrane and nanofiltration membrane.

[0031] The multi...

Embodiment 2

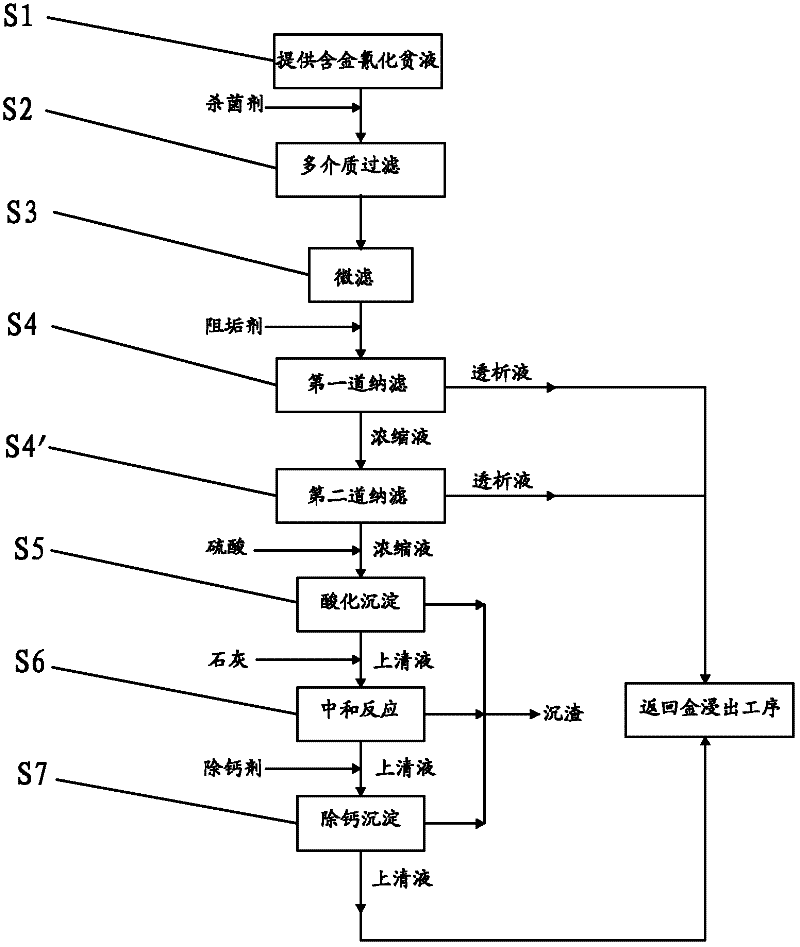

[0067] Such as figure 2 As shown, the main difference between embodiment two and embodiment one is to increase the second nanofiltration step S4' between the first nanofiltration step S4 and the acidification precipitation step S5, and other steps are all the same. Wherein, the second nanofiltration step S4' is specifically as follows, the concentrated solution obtained in the first nanofiltration step S4 is sieved and filtered through the second nanofiltration membrane, and the resulting dialysate is returned to the gold leaching process, and the resulting concentrated solution is Enter the next acidification precipitation step S5. In this embodiment, through the first nanofiltration step S4 and the second nanofiltration step S4', not only an effective interception effect can be achieved, the operating cost of the nanofiltration membrane equipment can be reduced, and the recovery of gold and cyanide in the gold-containing barren solution can be improved. The efficiency can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com