Method for treating aluminum lug

A processing method and a technology for a pole lug are applied in the processing field of aluminum pole lugs, which can solve the problems of increasing cost, increasing the process of converting aluminum strips to nickel, and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

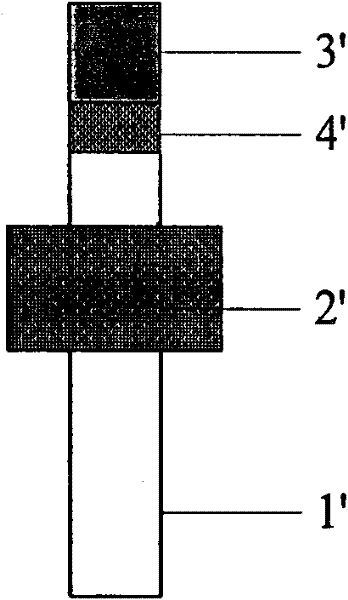

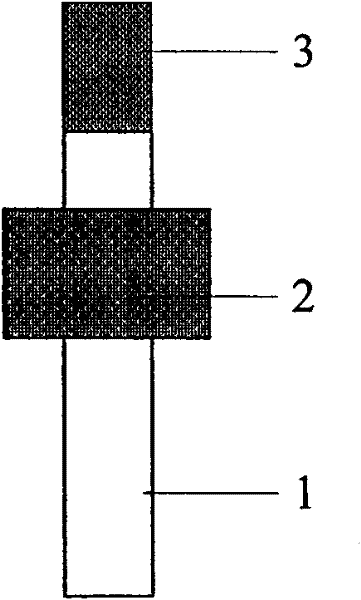

Method used

Image

Examples

Embodiment 1

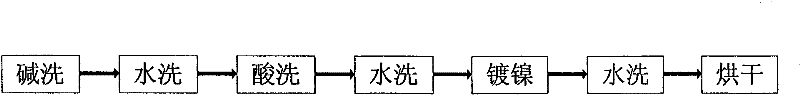

[0031] 1. Drug preparation

[0032] (1) Preparation of lye: Measure 500ml of distilled water and put it into a beaker, weigh 5g of potassium carbonate and 2g of potassium hydroxide into the water, stir with a strong mixer for about 5min until the solution becomes clear and transparent;

[0033] (2) Acid solution preparation: measure 500ml of distilled water and put it into a beaker, weigh 100g of concentrated hydrochloric acid and put it into the water;

[0034] (3) Preparation of treatment solution: Measure 1000ml of distilled water and put it into a beaker, weigh 33.0g of nickel sulfate, 33.0g of sodium hypophosphite, 9.3g of boric acid, 25g of sodium citrate, 30g of sodium acetate, and 3.0g of potassium iodate. Stir with a strong mixer for 10 minutes, adjust the pH value with sodium hydroxide, and keep the pH value of the treatment solution at about 9.0.

[0035] 2. Nickel-plated aluminum lugs

[0036] Electroless nickel plating is carried out according to the nickel plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com