Hdd pattern implant system

A substrate, processing chamber technology, applied in the field of hard disk drive media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

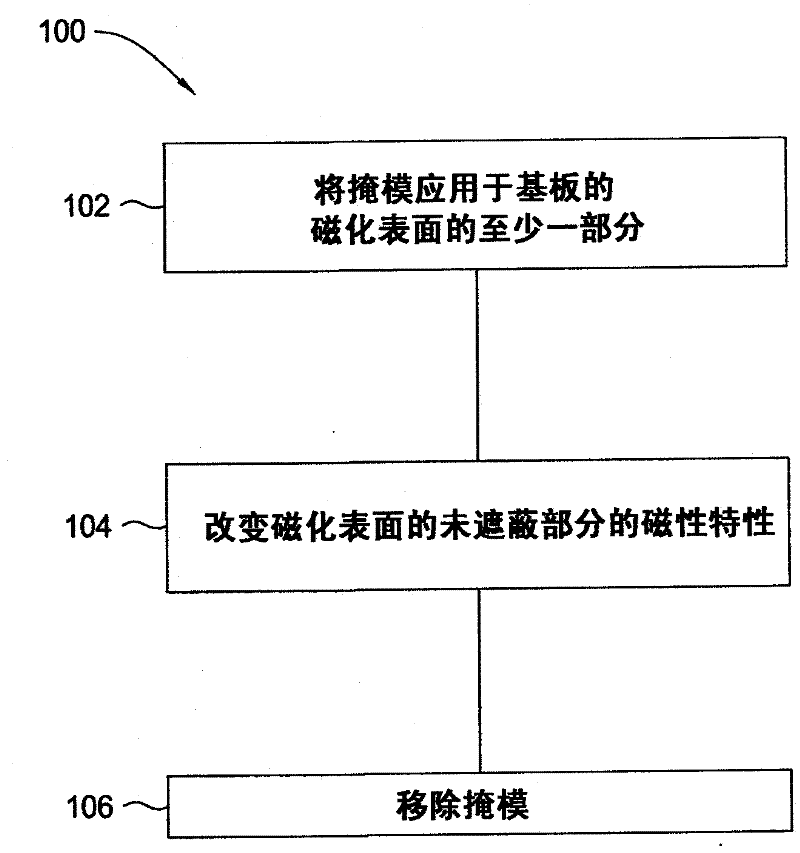

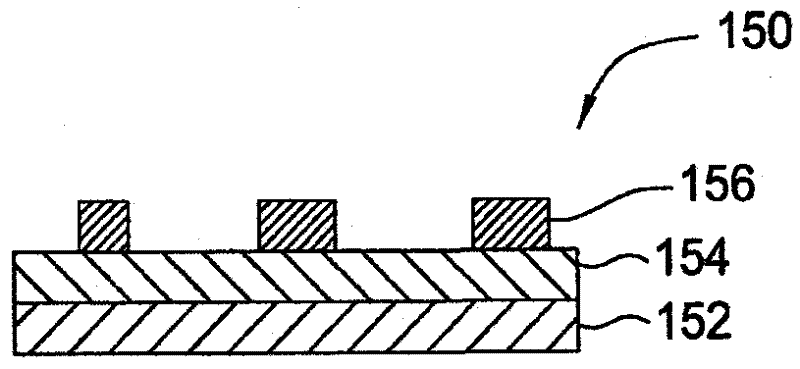

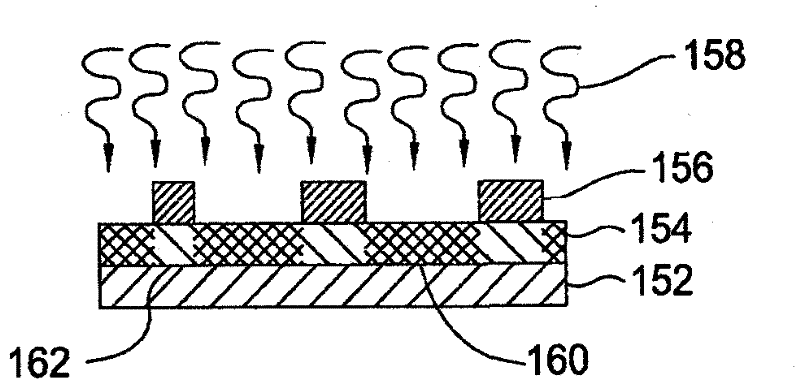

Method used

Image

Examples

example 1

[0121] Example 1 - Helium Injection

[0122] The glass substrate was sputtered with a soft magnetic layer of Fe-Ni alloy to a thickness of about 100 nm. The cobalt-chromium-platinum alloy magnetic film layer is sputtered on the iron-nickel alloy soft magnetic layer to a thickness of about 20nm. Samples prepared as described above were subjected to a plasma containing helium ions by providing helium gas into the processing chamber. The process chamber pressure was about 15 mTorr, the RF bias was about 2 kV, the power supply was about 500 W, helium was provided at a flow rate of about 300 sccm and the injection time was about 25 seconds. Helium ions were found to penetrate resist layers up to a thickness of about 85 nm. Implantation of helium ions in this manner reduces the saturation magnetic flux density of the exposed portion from 1.36 Tesla (T) to 0.1T. Although not used in this example, a second gas may be provided along with helium to aid in plasma formation. For examp...

example 2

[0124] Example 2 - Boron Implantation

[0125] A sample similar to that used in Example 1 was subjected to boron ion implantation. By providing BF to the processing chamber containing the sample 3 gas to subject samples prepared as described above to a plasma containing boron ions. The process chamber pressure was maintained at about 15 mTorr, the RF bias was about 9 kV, the power supply was about 500 W, and the BF was delivered at a flow rate of about 300 sccm 3 gas and the injection time is about 20 seconds. Boron ions were found to penetrate the resist layer up to a thickness of about 65 nm, and further penetrate the magnetic layer at a constant concentration up to a depth of about 10 nm, decreasing thereafter. As in Example 1, argon may also be used in this example to supplement plasma formation. The implanted boron ions reduced the saturation flux density of the sample from about 1.36 T to about 0.5 T, a reduction of more than 50%.

[0126] It is evident from the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com