Riding mower with noise reduction measure and hydraulic stepless speed change

A hydraulic stepless speed change, lawn mower technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of increased front and rear wheelbase, lengthened whole machine, increased cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

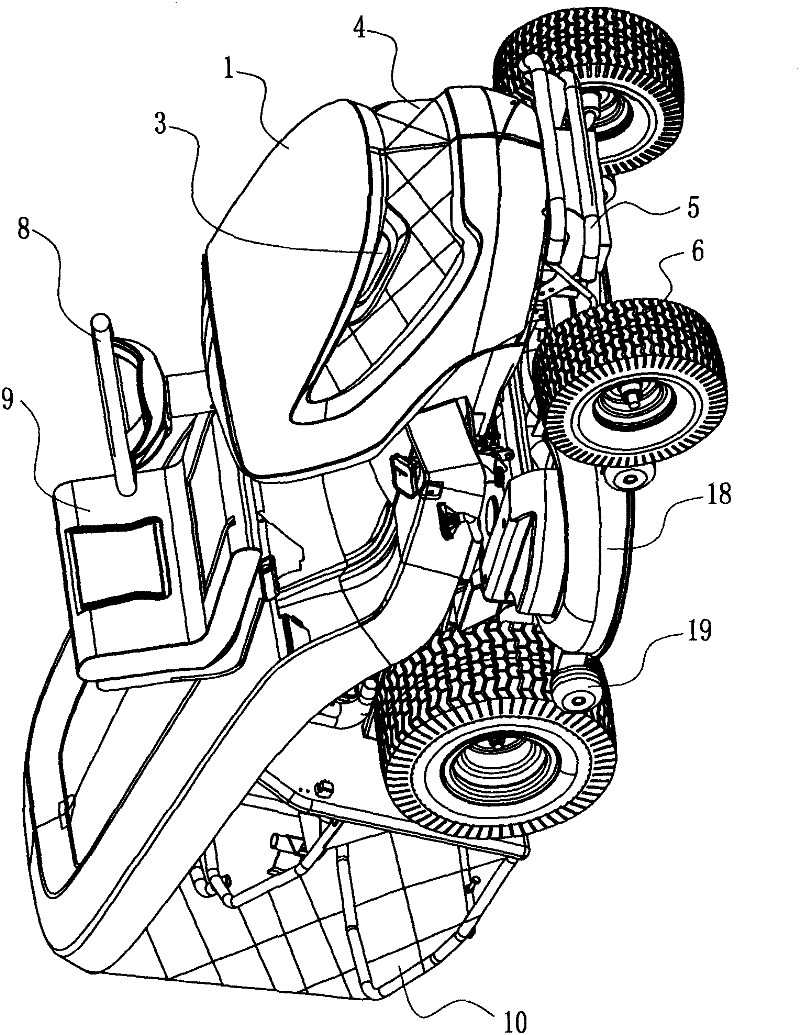

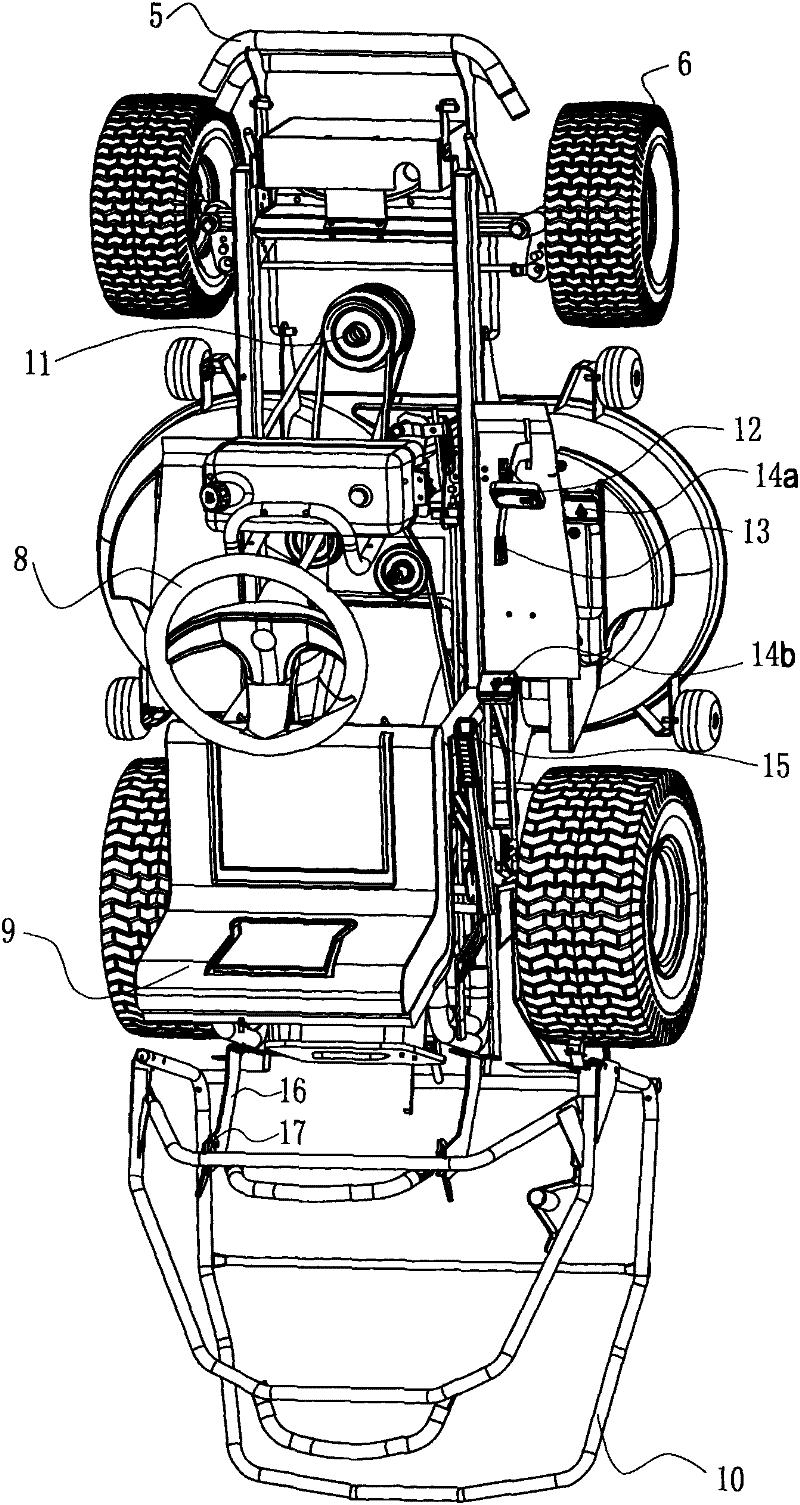

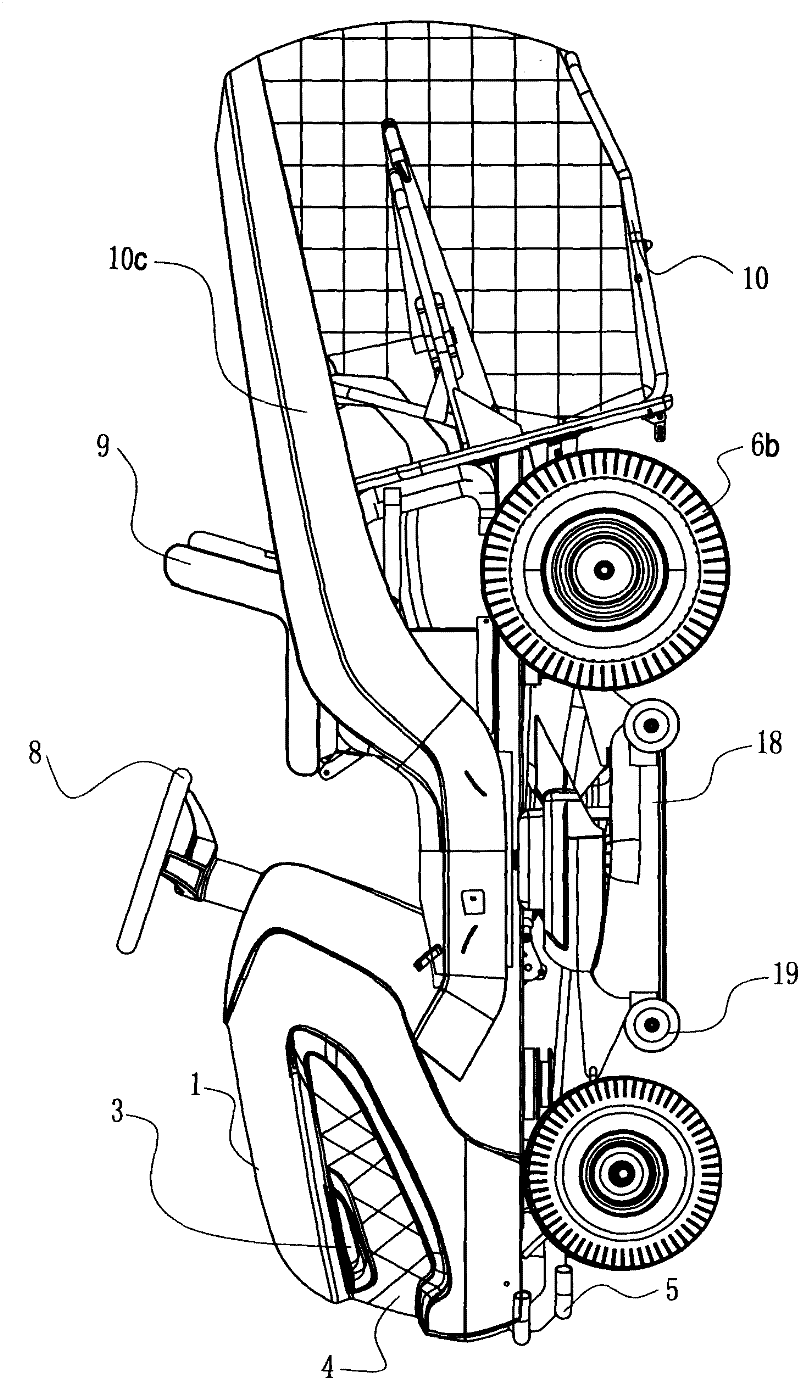

[0106] The invention relates to a riding lawnmower. The main purpose of improvement is to make the comprehensive effect not only favorable for wide mowing, comfortable operation, stepless speed change, but also favorable for noise reduction, environmental protection and safety. Because a variety of noise reduction measures and technical solutions and optimal graphic design methods have been adopted, the riding lawn mower with noise reduction measures and hydraulic stepless transmission includes a steerable front axle connecting two front wheels, connecting two Drivable rear axle with hydraulic continuously variable transmission at rear wheels, frame with double bumpers above all four wheels, noise-reducing lawn mower under frame, engine with sound-absorbing grooves above frame and forward And the noise-reducing head cover 1 and the noise-reducing air filter 4 are arranged, the vehicle seat with noise-reducing is arranged in the rear of the middle part above the vehicle frame, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com