Guar meal fermented protein feed additive, preparation method and feed containing guar meal fermented protein feed additive

A technology of fermented protein feed and guar soybean meal, which is applied in the field of microbial technology application, can solve the problems of low digestibility, difficult digestion and absorption, etc., and achieve the effects of improving nutritional value, reducing feed-to-egg ratio, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. After pulverizing 200g of guar soybean meal, pass it through a 20-mesh analytical sieve, then sterilize at 121°C for 30 minutes, and cool it for later use; another 200g of guar soybean meal is directly sterilized at 121°C for 30 minutes without crushing, and cool it for later use.

[0034] 2. Seed cultivation:

[0035] a. Preparation of seed medium: take 3% soybean meal, 1% glucose and tap water, sterilize at 121° C. for 30 minutes, and cool for later use;

[0036] b. Cultivation of Lactobacillus plantarum and Streptococcus faecalis: Take out the frozen glycerol tube strains of Lactobacillus plantarum and Streptococcus faecalis from the refrigerator. In the Erlenmeyer flask, culture at 40°C for 12 hours.

[0037] c. Culture of Saccharomyces cerevisiae:

[0038] Activation of active dry Saccharomyces cerevisiae starts 1 hour before inoculation: the amount of yeast used is 0.02% of the fermentation material, activated with 2% sugar aqueous solution at 40°C for 1 hour...

Embodiment 2

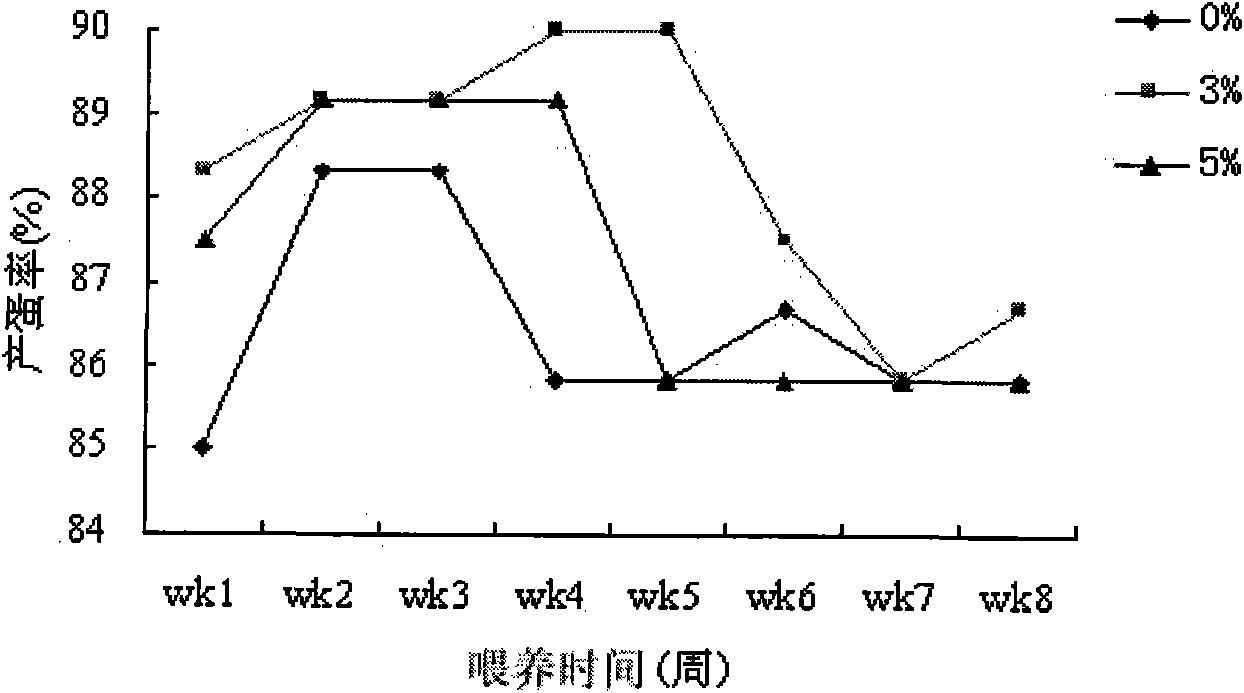

[0065] Experimental investigation was carried out on the protein feed added with the additive, and the production indicators such as the feed intake, egg production rate, egg weight, eggshell color, morbidity rate and death rate of laying hens at the peak laying period of the additive were investigated. Impact.

[0066] The protein feed, including the compound feed, also contains 3-5% of the additive by weight percentage.

[0067] The compound feed is 846s, provided by Haian Yuanyao Feed Co., Ltd.

[0068] (1) Experimental grouping: The experiment adopts single-factor experimental design, selects 360 Hainan gray laying hens that are 32 weeks old and are healthy and with similar body weight, and are randomly divided into three groups, one of which is the control group, and two groups are the experimental group, There were 120 chickens in each group, and three repetitions were set up for each experimental group. The principle of experimental design followed that the experiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com