Method for preparing super-hydrophobic nano-magnetic thin film

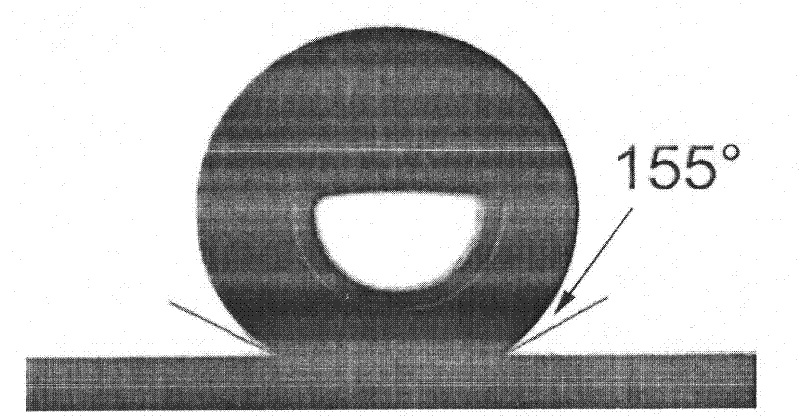

A nano-magnetic and super-hydrophobic technology, applied in the direction of the magnetic layer, can solve the problems of limiting the application range of super-hydrophobic nano-magnetic materials, high process requirements, and high cost, and achieve excellent super-hydrophobic performance, broad application prospects, and preparation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

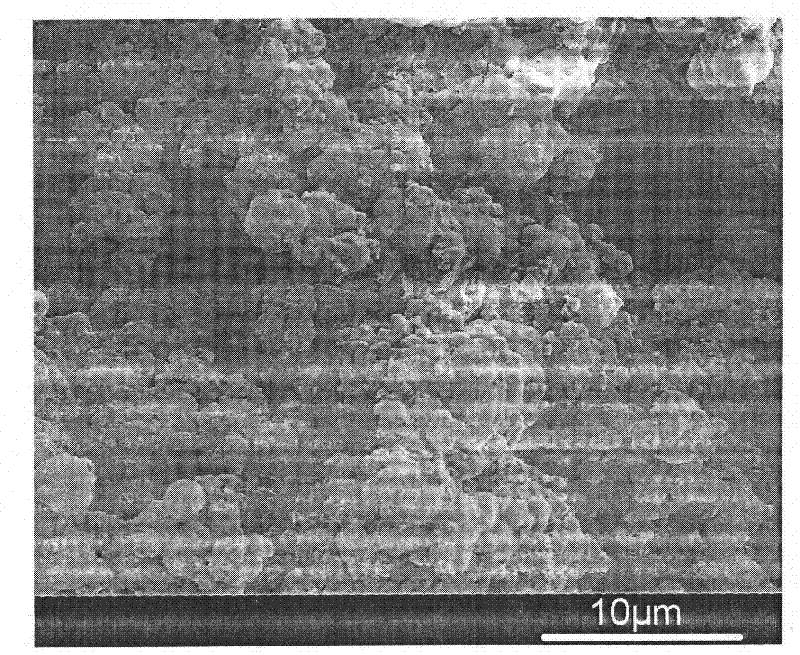

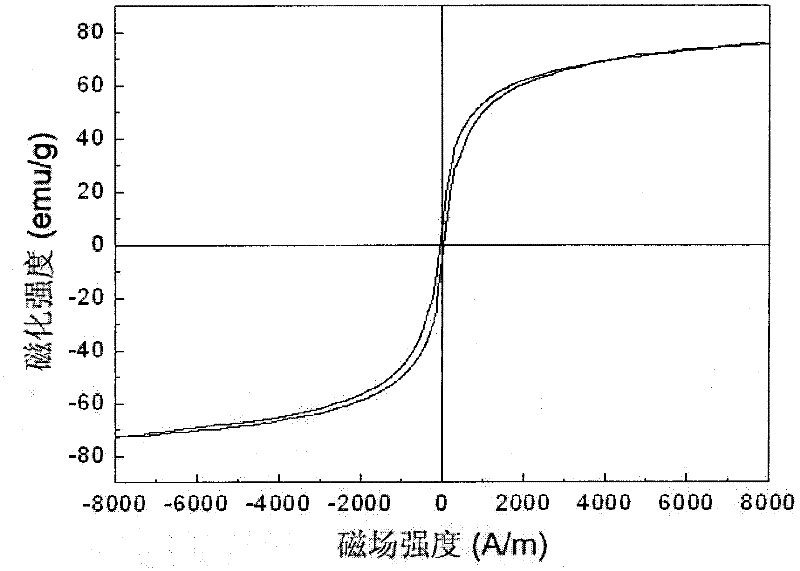

[0025] 1. Preparation of nano-iron oxide-silica core-shell particles

[0026] 1.5g γ-Fe 2 o 3 Put it into a three-necked flask, then add 25mL of ammonia water, 200mL of absolute ethanol and 50mL of distilled water, ultrasonically disperse for 10 minutes, then add 5mL of tetraethyl orthosilicate, stir and react for 12 hours at 30°C, wash and centrifuge 3 to 5 times , and then dried at 100°C for 3 hours to obtain nano-γ-Fe 2 o 3 - Core-shell nanoparticles of silica.

[0027] 2. For nanometer γ-Fe 2 o 3 - Silica core-shell particles for surface modification

[0028] Weigh the above nano γ-Fe 2 o 3 - Disperse 1g of silica core-shell particles into 100mL of absolute ethanol, then add 10mL of vinyltriethoxysilane and 10mL of ammonia water, react at 30°C for 24 hours, then centrifuge and dry to obtain a surface covered with vinyl Modified Nano γ-Fe 2 o 3 - Silica core-shell particles.

[0029] 3. Preparation of nanometer γ-Fe 2 o 3 - Silica-polystyrene composite

[003...

Embodiment 2

[0037] 1. Preparation of nano-iron oxide-silica core-shell particles

[0038] 1g Fe 3 o 4 Put it into a three-necked flask, then add 20mL of ammonia water, 150mL of absolute ethanol and 40mL of distilled water, ultrasonically disperse for 10 minutes, then add 4mL of ethyl orthosilicate, stir and react for 15 hours at 25°C, wash and centrifuge 3 times, and finally Dry at 100°C for 3 hours to prepare nano-Fe 3 o 4 - Silica core-shell particles.

[0039] 2. On nano Fe 3 o 4 - Silica core-shell particles for surface modification

[0040] Weigh the above nano-Fe 3 o 4 - Disperse 1g of silica core-shell particles into 120mL of absolute ethanol, then add 10mL of vinyltriethoxysilane and 10mL of ammonia water, react at 25°C for 24 hours, then centrifuge and dry to obtain a surface covered with vinyl modified nano-Fe3 o 4 - Silica core-shell particles.

[0041] 3. Preparation of nano-iron oxide-silica-polystyrene composites

[0042] Nano-Fe modified by vinyl group on the su...

Embodiment 3

[0046] 1. Preparation of nano-iron oxide-silica core-shell particles

[0047] 1g γ-Fe 2 o 3 Put it into a three-necked flask, then add 20mL of ammonia water, 150mL of absolute ethanol and 40mL of distilled water, ultrasonically disperse for 10 minutes, then add 4mL of ethyl orthosilicate, stir and react for 12 hours at 30°C, wash and centrifuge 3 times, and finally Dry at 100°C for 3 hours to prepare nanometer γ-Fe 2 o 3 - Core-shell nanoparticles of silica.

[0048] 2. Surface modification of nano-iron oxide-silica core-shell particles

[0049] Weigh the above nano γ-Fe 2 o 3 - 1g of core-shell nanoparticles of silica, dispersed in 120mL of absolute ethanol, then added 12mL of 3-(methacryloyloxy)propyltrimethoxysilane and 10mL of ammonia water, reacted at 30°C for 24 hours, and then centrifuged and dry to obtain surface-modified nano-γ-Fe 2 o 3 - Core-shell nanoparticles of silica.

[0050] 3. Preparation of nano-iron oxide-silica-polystyrene composites

[0051] Na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com