White-light LED (Light-emitting Diode) manufactured by utilizing quantum-dot fluorescent powder and manufacturing method thereof

A technology of quantum dots and phosphors, which is applied in the field of white LED and its preparation, can solve problems such as low color rendering, narrow color gamut, and poor stability, and achieve the effects of low operating temperature, short production time, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

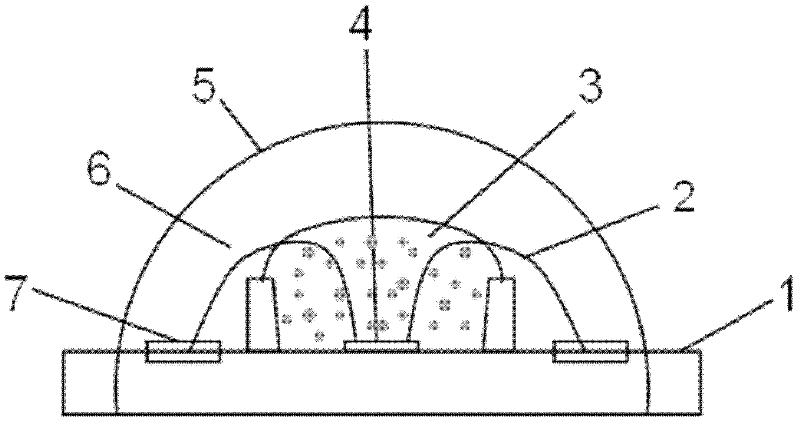

[0028] Such as figure 1 As shown, the white light LED manufactured by using quantum dot phosphor powder of the present invention includes a heat dissipation base 1, gold wire 2, quantum dot and silica gel mixture 3, purple or blue light chip 4, light-taking lens 5, filled silica gel 6 and electrodes 7. Two electrodes 7 are fixed on both ends of the heat dissipation base 1, and the purple or blue light chip 4 is fixed on the heat dissipation base 1 and between the two electrodes. The two electrodes are respectively connected to the purple or blue light chip 4 through gold wires 2, The quantum dot and silica gel mixture 3 is covered on the purple or blue light chip 4, and the silica gel 6 is filled. Two electrodes 7, the gold wire 2, the quantum dot and silica gel mixture 3 and the purple or blue light chip 4 are covered on the heat dissipation base 1, and the silica gel 6 is filled. A light-taking lens 5 is arranged on the outside. Among them, the quantum dots are carbon quant...

Embodiment 2

[0030] Its LED structure is the same as in Embodiment 1. The quantum dot fluorescent powder is a mixed quantum dot in which blue carbon quantum dots and yellow CdTe quantum dots are compounded at a ratio of 5:1, and then the quantum dot mixture is mixed in silica gel at a ratio of 10:90, and coated on the existing On the violet chip (the emission wavelength is 370nm) with the crystal bonded wire fixed, bake at 150°C for 60 minutes to cure, cover the lens, and fill the lens with high refractive index filling glue, and then place it in an oven at 150°C The white light LED can be prepared after the filling glue is cured by lower baking for 60 minutes.

Embodiment 3

[0032] Its LED structure is the same as in Embodiment 1. The quantum dot fluorescent powder is blue, yellow and red carbon quantum dots mixed with quantum dots in a ratio of 1:2:3, and then the quantum dot mixture is mixed in silica gel at a ratio of 15:85, and coated Bake at 150°C for 60 minutes on the violet chip (with an emission wavelength of 390nm) that has been fixed and bonded to make it solidify, cover the lens, and fill the lens with high refractive index filler, and then place it in the oven Baking at 150° C. for 60 minutes to cure the filler can produce a white LED.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com