Method for rapidly starting anaerobic ammonium oxidation reactor

A technology of anaerobic ammonium oxidation and quick start, applied in the field of quick start anaerobic ammonium oxidation reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

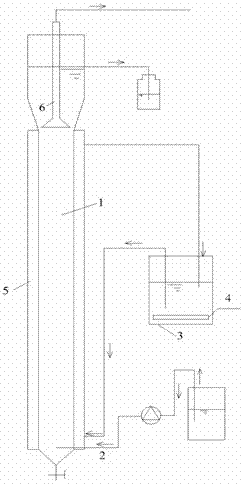

[0024] Anaerobic activated sludge was used as the inoculum, bamboo charcoal was used as the sludge carrier, and an upflow anaerobic sludge bed reactor was used as the reaction device to domesticate and cultivate anaerobic ammonium oxidation sludge under the condition of anaerobic shading.

[0025] Anaerobic nitrification sludge from a municipal sewage treatment plant and a brewery wastewater treatment plant were used as inoculation sludge, mixed 1:1 (3.5 L each) into the upflow anaerobic sludge bed reactor, and the mixing ratio was 10 L The reactor was fed with 70% anaerobic digested sludge. Bamboo charcoal is used as the starting carrier of anaerobic ammonium oxidation reaction, the addition amount is 4% (V / V), the diameter of bamboo charcoal particles is 3-5 mm, and the specific surface area is 14.0-31.2 m 2 / g, the density is 750 kg / m 3 , with a bulk density of 520 kg / m 3 . The operating conditions are: the concentration of ammonia nitrogen in the simulated wastewater is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com