Calcium stearate fusion production process and calcium stearate reaction kettle thereof

A technology of calcium stearate and production process, applied in the field of calcium stearate melting method production technology, can solve problems such as uneven stirring, uneven reaction, difference in quality of upper and lower products, and achieve stable product quality and speed up reaction rate. , the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

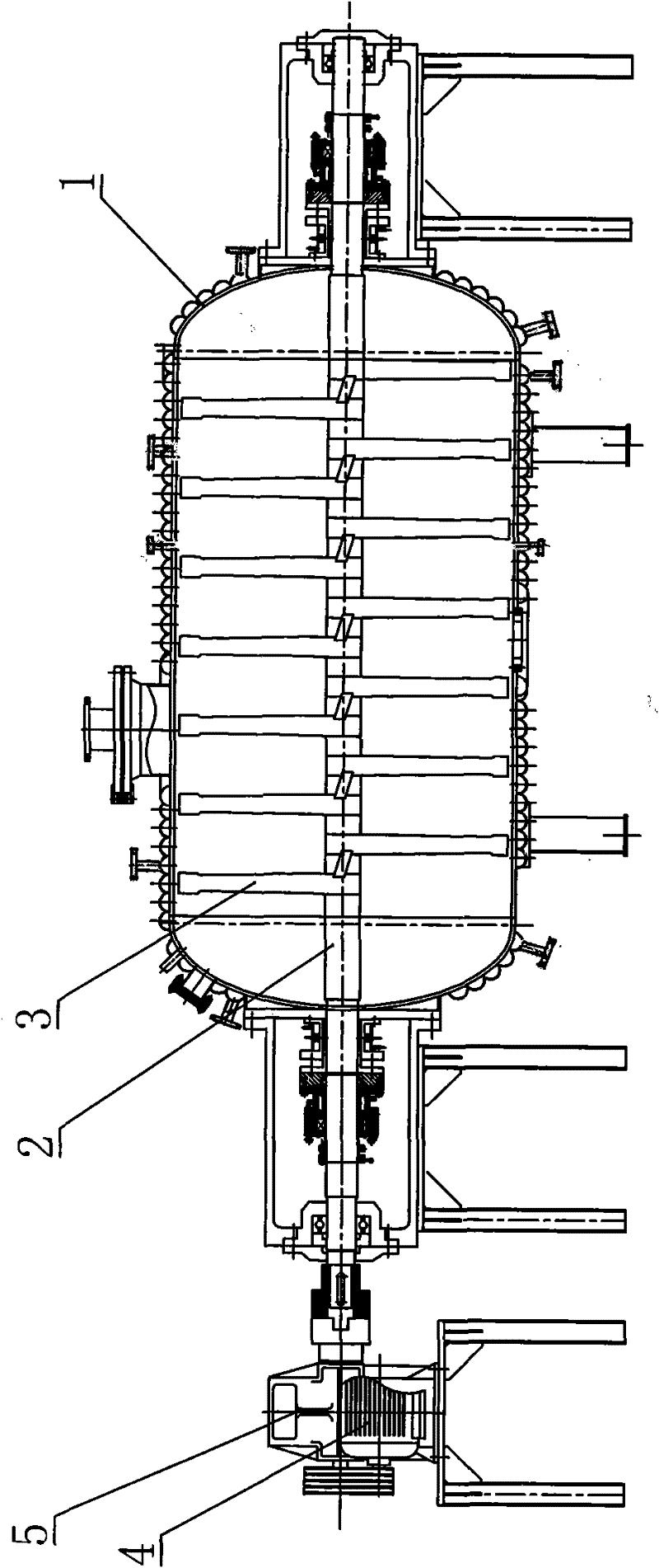

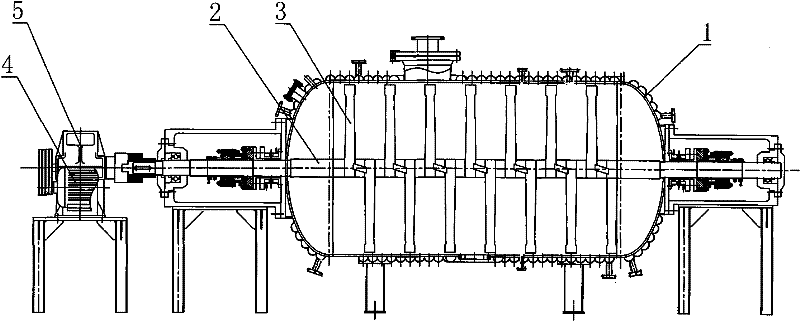

[0015] First, preheat the stearic acid: transport the stearic acid in the liquid state into the calcium stearate reactor through the pump and the pipeline, control the addition amount of the stearic acid through the flow meter installed on the pipeline, and put the stearic acid The stearic acid in the calcium reactor is heated to 150-180°C. The calcium stearate reactor involved in the present invention includes a kettle body 1, a stirring shaft 2, a stirring paddle 3, a motor 4, and a reducer 5. The kettle body 1 is a horizontal kettle body arranged horizontally, and a horizontal stirring shaft 2 is arranged inside the kettle body 1. Seven sets of stirring paddles 3 are installed on the stirring shaft 2, and each group of stirring paddles 3 is two vertically arranged The scraper type paddle; Kettle body 1 is provided with motor 4, and it is connected with stirring shaft 2 through reducer 5;

[0016] Add calcium hydroxide and catalyst, add calcium hydroxide and catalyst in thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com